All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

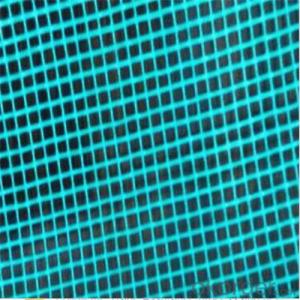

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What are the steps for integrating fiberglass mesh into concrete countertops?

The steps for integrating fiberglass mesh into concrete countertops are as follows:

1. Prepare the countertop surface by cleaning it thoroughly and ensuring it is free of any dust or debris.

2. Cut the fiberglass mesh to fit the dimensions of the countertop, leaving a slight overlap on the edges.

3. Apply a thin layer of concrete mix or slurry onto the countertop surface.

4. Carefully place the fiberglass mesh onto the wet concrete, ensuring it is evenly distributed and covers the entire surface.

5. Use a trowel or float to press the mesh into the concrete, ensuring it is fully embedded and any air pockets are eliminated.

6. Apply another layer of concrete mix or slurry over the mesh, completely covering it and smoothing out any imperfections.

7. Allow the concrete to cure according to the manufacturer's instructions.

8. Once cured, sand the countertop surface to achieve a smooth finish.

9. Apply a sealer or finish to protect the countertop and enhance its appearance.

10. Allow the sealer to dry completely before using the countertop.

Can fiberglass mesh be used for reinforcing decks?

Yes, fiberglass mesh can be used for reinforcing decks. It is commonly used to add strength and durability to the surface of the deck, preventing cracks and minimizing movement.

How does fiberglass mesh improve the bonding of surfaces?

Fiberglass mesh improves the bonding of surfaces by providing a strong, stable, and textured surface for adhesives or coatings to adhere to. The mesh creates a mechanical bond with the adhesive, enhancing its strength and durability. Additionally, the mesh helps distribute the stress and weight evenly across the surface, preventing cracks and delamination.

Can fiberglass mesh be used for reinforcing fiberglass sculptures?

Yes, fiberglass mesh can be used for reinforcing fiberglass sculptures. It provides strength and stability to the sculpture, helping it withstand external forces and prevent cracking or breaking.

Wholesale Fiberglass Mesh from supplier in Malawi

Whether you are in the construction, agriculture, or industrial sector, our Fiberglass Mesh products are designed to meet your specific requirements. Our team of experts can assist you in selecting the right product for your application, ensuring optimal performance and durability.

In addition to providing high-quality products, we are committed to delivering exceptional customer service. Our dedicated sales team is available to assist you with any inquiries, provide detailed quotations, and offer technical support throughout your project. We strive to establish long-term relationships with our customers, built on trust and reliability.

As a subsidiary of CNBM, a global leader in building materials and construction industries, we have access to state-of-the-art manufacturing facilities and cutting-edge technology. This enables us to consistently deliver superior Fiberglass Mesh products that meet international quality standards.

Furthermore, our extensive network and presence in the Malawi market allow us to understand the unique challenges and requirements of the local industry. We can provide valuable insights and expertise to help you make informed decisions and optimize your projects.

Whether you need Fiberglass Mesh for reinforcement, insulation, or filtration purposes, we have the right solution for you. Contact us today to discuss your requirements and let us be your trusted partner for all your Fiberglass Mesh needs in Malawi.

In addition to providing high-quality products, we are committed to delivering exceptional customer service. Our dedicated sales team is available to assist you with any inquiries, provide detailed quotations, and offer technical support throughout your project. We strive to establish long-term relationships with our customers, built on trust and reliability.

As a subsidiary of CNBM, a global leader in building materials and construction industries, we have access to state-of-the-art manufacturing facilities and cutting-edge technology. This enables us to consistently deliver superior Fiberglass Mesh products that meet international quality standards.

Furthermore, our extensive network and presence in the Malawi market allow us to understand the unique challenges and requirements of the local industry. We can provide valuable insights and expertise to help you make informed decisions and optimize your projects.

Whether you need Fiberglass Mesh for reinforcement, insulation, or filtration purposes, we have the right solution for you. Contact us today to discuss your requirements and let us be your trusted partner for all your Fiberglass Mesh needs in Malawi.