All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the tin coating affect the corrosion resistance of electrolytic tinplate sheet?

The tin coating on electrolytic tinplate sheet enhances its corrosion resistance by acting as a protective barrier between the metal substrate and the surrounding environment. The tin layer prevents direct contact between the iron or steel base and moisture, oxygen, or other corrosive agents, thereby reducing the likelihood of rust or corrosion. Additionally, the tin coating can also provide sacrificial protection, meaning that even if the coating is compromised, the tin will corrode first before the base metal, further safeguarding the sheet from degradation.

What are the different printing techniques suitable for electrolytic tinplate sheet?

Some of the different printing techniques suitable for electrolytic tinplate sheet include offset printing, flexographic printing, and digital printing. These methods allow for high-quality and durable prints on the tinplate surface, ensuring excellent visual appeal and branding opportunities for various packaging and promotional materials.

Can electrolytic tinplate sheet be used for packaging canned baked goods?

Yes, electrolytic tinplate sheet can be used for packaging canned baked goods. It provides a protective barrier against moisture and oxygen, ensuring the freshness and shelf life of the baked goods. Additionally, it is resistant to corrosion, making it suitable for food packaging.

What are the safety considerations when handling electrolytic tinplate sheet?

When handling electrolytic tinplate sheet, it is important to consider several safety measures. First, proper personal protective equipment (PPE) should be worn, including gloves, safety glasses, and protective clothing to prevent cuts, burns, or exposure to chemicals. Additionally, workers should be trained on safe handling techniques, such as lifting with proper body mechanics and avoiding sharp edges. It is crucial to store the sheets in a well-ventilated area to prevent the buildup of harmful gases. Lastly, fire safety precautions should be taken, such as keeping the sheets away from open flames or sparks.

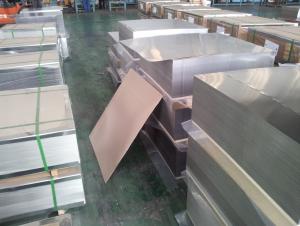

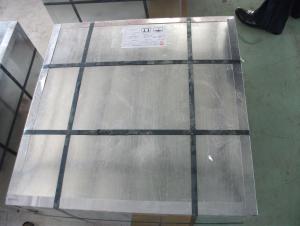

Wholesale Electrolytic Tinplate Sheet from supplier in Malawi

Whether you are in need of Electrolytic Tinplate Sheets for packaging, canning, or any other application, we have you covered. Our team of experts is dedicated to understanding your specific requirements and providing tailored solutions to meet your needs. We offer competitive prices and flexible payment terms to ensure that you receive the best value for your investment.

In addition to our sales services, we also provide comprehensive technical support to assist you throughout the procurement process. Whether you have questions about product specifications, application guidelines, or any other technical aspect, our knowledgeable team is ready to assist you.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver efficient and reliable services. Our strong global network enables us to source high-quality products and ensure timely delivery to your location in Malawi.

We understand the unique challenges and opportunities in the Malawi market, and our experience allows us to offer valuable insights and expertise. We can help you navigate through local regulations, market trends, and other factors to optimize the success of your projects.

Contact us today to discuss your Electrolytic Tinplate Sheets requirements in Malawi. We are committed to providing you with exceptional products, services, and support to help you achieve your goals.

In addition to our sales services, we also provide comprehensive technical support to assist you throughout the procurement process. Whether you have questions about product specifications, application guidelines, or any other technical aspect, our knowledgeable team is ready to assist you.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to deliver efficient and reliable services. Our strong global network enables us to source high-quality products and ensure timely delivery to your location in Malawi.

We understand the unique challenges and opportunities in the Malawi market, and our experience allows us to offer valuable insights and expertise. We can help you navigate through local regulations, market trends, and other factors to optimize the success of your projects.

Contact us today to discuss your Electrolytic Tinplate Sheets requirements in Malawi. We are committed to providing you with exceptional products, services, and support to help you achieve your goals.