All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

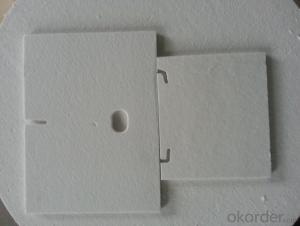

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

What are the common refractory materials used for lining tundishes?

The common refractory materials used for lining tundishes include alumina, magnesia, and zirconia-based refractories.

What are the common shapes and sizes of refractory bricks?

The common shapes of refractory bricks include rectangular, square, trapezoidal, and circular. The sizes of refractory bricks vary depending on their intended application, but they are typically available in dimensions ranging from standard sizes like 9" x 4.5" x 2.5" to larger sizes such as 9" x 9" x 4.5".

What are the advantages of using refractory insulation materials?

There are several advantages of using refractory insulation materials. Firstly, they have high heat resistance capability, allowing them to withstand extremely high temperatures without degradation. This makes them suitable for applications in industries such as metal processing, glass manufacturing, and cement production. Secondly, refractory insulation materials have excellent thermal insulation properties, reducing heat transfer and improving energy efficiency. They can effectively retain heat within furnaces, kilns, and other equipment, resulting in lower energy consumption and cost savings. Additionally, these materials offer good chemical resistance, protecting against corrosion and erosion caused by harsh chemicals and molten metals. Lastly, refractory insulation materials have a long lifespan and require minimal maintenance, making them a cost-effective choice in the long run.

What are the challenges faced by refractory materials in the heating and ventilation industry?

One of the main challenges faced by refractory materials in the heating and ventilation industry is their ability to withstand high temperatures. These materials need to be able to withstand the extreme heat generated by heating systems without cracking or deteriorating. Additionally, refractory materials need to have good thermal conductivity to efficiently transfer heat, while also being resistant to thermal shocks and chemical corrosion. Another challenge is finding refractory materials that are cost-effective and have a long lifespan, as frequent replacements can be costly and time-consuming. Overall, the challenges lie in balancing durability, thermal resistance, and cost-effectiveness in order to meet the demanding requirements of the heating and ventilation industry.

Wholesale Refractory Materials from supplier in France

With our specialization in supplying Refractory Materials in France, we are dedicated to offering a wide range of products to meet your needs. Our services go beyond just sales and quotation; we also provide technical support to ensure that you have all the necessary information and guidance for your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with a complete one-stop solution. Whether you are looking for basic refractory materials or specialized products for specific industries, we have you covered.

Our extensive product portfolio caters to various industries, including steel, cement, glass, petrochemical, and more. We understand the unique requirements and challenges of each industry, and our years of market presence in France have allowed us to develop a deep understanding of the local market dynamics.

By choosing us as your supplier, you can benefit from our experience and expertise. We can provide valuable insights and support to help you make informed decisions and enhance the success of your ventures. Whether you need assistance with product selection, technical specifications, or project planning, our team is here to help.

We invite you to explore our offerings and discover the quality and reliability of our refractory materials. Contact us today to discuss your requirements and let us be your trusted partner for all your Refractory Materials procurement needs in France.

As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and capabilities to provide you with a complete one-stop solution. Whether you are looking for basic refractory materials or specialized products for specific industries, we have you covered.

Our extensive product portfolio caters to various industries, including steel, cement, glass, petrochemical, and more. We understand the unique requirements and challenges of each industry, and our years of market presence in France have allowed us to develop a deep understanding of the local market dynamics.

By choosing us as your supplier, you can benefit from our experience and expertise. We can provide valuable insights and support to help you make informed decisions and enhance the success of your ventures. Whether you need assistance with product selection, technical specifications, or project planning, our team is here to help.

We invite you to explore our offerings and discover the quality and reliability of our refractory materials. Contact us today to discuss your requirements and let us be your trusted partner for all your Refractory Materials procurement needs in France.

Hot Search

- Monolithic Refractories in Swaziland

- Ceramic Fiber Products in Jordan

- Refractory Bricks in Iran

- Raw Materials For Refractory in Mexico

- Ceramic Fiber Products in Benin

- Raw Materials For Refractory in Barbados

- Ceramic Fiber Products in Madagascar

- Monolithic Refractories in Serbia

- Ceramic Fiber Products in Dominican

- Raw Materials For Refractory in British