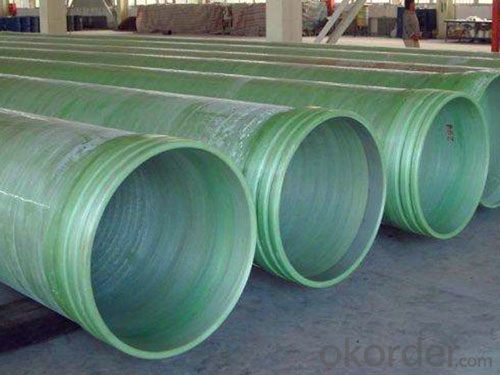

Composite FRP Process Pipe/Light Weight and High Strength FRP Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of FRP Process Pipe Description

1) Antifouling, anti-moth, non-rust, keeping water from pollution; It also apply to carry the polluted water, slurry and seawater;

2) The ability of water resistance and corrosion resistance can prolong product service life;

3) The connection of insert makes airproof excellent; project cost can be reduced without building concrete protect layer;

4) Few joint and various of joint methods not only reduce water resistance but also project cost;

5) Good insulation, heat resistance, combustration resistance; No distortion in high temperature of 80-100 degree;

6) With light weight, high strength, the hoisting cost can be decreased, also expedite installation proceeding;

7) Low maintenance expense: no need for antirust, anti-pollution, insulation, heat preservation and the relative examination and repair; cathode protection free also can save the project maintenance cost.

2. Main Features of FRP Process Pipe

1) Corrosion resistance

2) Lightweighta high strength

3) Easy installation

4) Low temperature-perform

3. FRP Process Pipe Images

4. FRP Process Pipe Specification

1)Small specific gravity, light weight: FRP pipe’s specific gravity is 1.65-2.0 and one 1/4 compared with steel; hoop flexible tensile strength for FRP pipe is 150-420 MPa and axis tensile strength is 60-150MPa, similar to alloy steel. FRP pipe’s strength/specific gravity is 2 or 3 times compared with alloy steel so it can be designed according to customers different requirements for various pips bearing inside and outside pressure. For the same diameter pipe, FRP pipe’s weight is 1/2.5 compared with carbon steel pipe, 1/3.5 compared with cast iron pip, 1/8 compared with reinforced concrete pipe, so it’s easy for construction and transporting.

2) Fewer joints and efficient installment: Usual pipe’s length is 4-12 meters(other special length is also available according to customer demands). Single pipe is long with few joints to accelerate installment speed and reduce the fault possibility then improve efficiency of quality of construction of whole pipe.

5. FAQ of FRP Process Pipe

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

One of the leading manufacturers and suppliers specializing in FRP pipe products in China. The integrated sales & service ensures customers with various demands an easier access for purchasing management.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: How can I replace the valve on the water supply pipe?

- According to the position of the branch pipe, the position of the opening is reasonably determined, and the position of the socket of the glass steel pipe is avoided as far as possible, and a better position is selected in the middle of the pipe body;

- Q: Mending method for glass fiber reinforced plastic pipe

- The method for mending and mending the glass fiber reinforced plastic pipe is hand paste, and the repairing steps are as follows:The stones must be taken away so that the pipes are restored to their original shape.Into the pipe, grinding first and lining the lining. If you can't get into the pipe, polish it from the outside, polish it to the lining, and then make a new lining.Reinforce the structure with a cloth.

- Q: Glass fiber reinforced plastic sand pipe backfill 5m, how much kg pressure?

- In general, glass steel pressure refers to the internal pressure, the conveying pressure of water, and you said the backfill produces is the external pressure, often say that the stiffness parameter.

- Q: The difference between GRP cable duct and PVC cable pipe

- PVC cable pipe refers to various kinds of rigid PVC pipes made of PVC resin as main raw material and various stabilizers.

- Q: Underground garage inorganic glass fiber reinforced plastic wind pipe water out of the way?

- Condensate water leaking from the interface of the pipe flange: when the pipe carries the airflow, it condenses the water molecules in the air and is concentrated at the lower part of the pipe due to speed, compression and other reasons. When the flange facing the gap is encountered at the low point, it will leak out of the pipe.

- Q: What are the specifications of glass fibre reinforced plastic cable pipes? What are they?

- FRP cable pipe is a new type of composite material, it mainly resin as adhesive, glass fiber as reinforcing agent, quartz sand as the supplementary material, formed by microcomputer control winding machine manufacturing, it has the strength of resistance to high pressure, weight, easy installation, safe and reliable, strong performance of insulation, corrosion can be anti corrosive the items, the anti parameter Water Leakage ability, but also has the advantages of long service life, can reach more than 50 years, because the FRP cable protection pipe set has various advantages of the industry, the performance has exceeded the same industry plastic pipe performance, it becomes popular industry engineering personnel.

- Q: Would like to ask about the plastic lined steel pipe, steel pipe, glass steel skeleton, the advantages and disadvantages of each ceramic pipe, to know a friend told, very grateful!

- Plastic lined steel pipe of strong corrosion resistance, heavy quality, need to be made, on-site installation, if the size deviation cannot be installed. The price is more than 5 times more expensive than that of FRP

- Q: What epoxy resin is used for anticorrosion of pipeline glass fiber reinforced plastics?

- General glass fiber reinforced plastic, no corrosion protection.If buried with epoxy coal pitch can be, anti rust grade Sa2.5, six oil four cloth can.

- Q: What is the compressive strength of all kinds of FRP materials?

- Anti fouling and anti moth: unsaturated polyester resin surface clean and smooth, will not be ocean or sewage in the shellfish, fungi and other microorganisms stained, moth, so as to increase roughness, reduce water cross section, increase maintenance costs. FRP pipes are free from these pollution and are clean for a long time. At the same time, because of its smooth inner wall and excellent corrosion resistance, it will not cause scale and microbial growth, effectively guarantee water quality and maintain the stability of water resistance. But the traditional pipe still exist after water resistance increases and the surface fouling phenomenon.

- Q: What are FRP pipes used for making? What raw materials?

- So people began to think, if you can make a kind of glass has both hardness, high temperature resistance, corrosion resistance of the nature, but also with steel as hard, not broken characteristics, then this material will be of great use. People have made such a composite material after research and experiment. It is a glass pipe and steel, can stand shoulder to shoulder.

Send your message to us

Composite FRP Process Pipe/Light Weight and High Strength FRP Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords