GRP FRP Flange Adaptor Sea Water Pipe Series DN 600

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features & Benefits of GRP FRP Flange Adaptor sea water pipe series

Corrosion-resistant

•Long, effective service-life materials

•No need for linings, coatings, cathodic protection, wraps or other forms of corrosion protection

•Low maintenance costs

•Hydraulic characteristics essentially constant over time

Light weight

(1/4 weight of ductile iron; 1/10 weight of concrete)

•Low transport costs (nestable)

•Eliminates need for expensive pipe handling equipment

Long standard lengths

(6, 12 metres)

•Fewer joints reduce installation time

•More pipe per transport vehicle means lower delivery costs

Extremely smooth bore

•Low friction loss means less pumping energy needed and lower operating costs

•Minimum slime build-up can help lower cleaning costs

Precision sealability

With elastomeric rubber rings

•Tight, efficient joints designed for bell & spigot to eliminate infiltration and ex-filtration

•Ease of joining, reducing installation time

• Accommodates small changes in line direction without fittings or differential settlement

Flexible manufacturing

•Custom diameters can be process manufactured to provide maximum flow volumes with ease of installation for rehabilitation

lining projects

High technology pipe design

•Lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures

High technology pipe manufacturing system producing pipe that complies to stringent performance standards (AWWA, ASTM, DIN, EN, etc.)

•High and consistent product quality worldwide which ensures reliable product performance

Control Testing of GRP FRP Flange Adaptor sea water pipe series

Raw Materials

Raw materials are delivered with vendor certification demonstrating their compliance with Zhongfu Lianzhong quality requirements. In addition, all raw materials are sample tested prior to their use. These tests ensure that the pipe materials comply with the specifications as stated

Physical Properties

The manufactured pipe’s hoop and axial load capacities are verified on a routine basis. In addition, pipe construction and composition are confirmed.

Finished Pipe

All pipes are subjected to the following control checks:

• Visual inspection

• Barcol hardness

• Wall thickness

• Section length

• Diameter

• Hydrostatic leak tightness test to 1.5 rated pressure (only PN6 and above)

On a sampling basis, the following control checks are performed:

• Pipe stiffness

• Deflection without damage or structural failure

• Axial and circumferential tensile load capacity

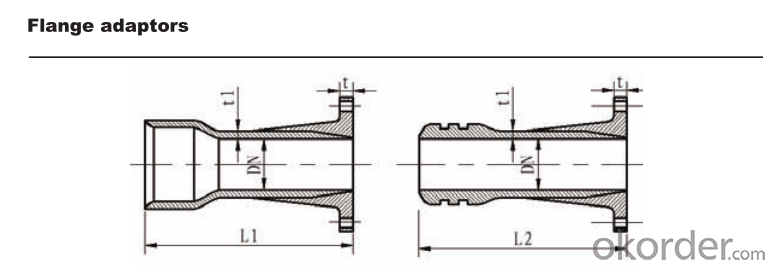

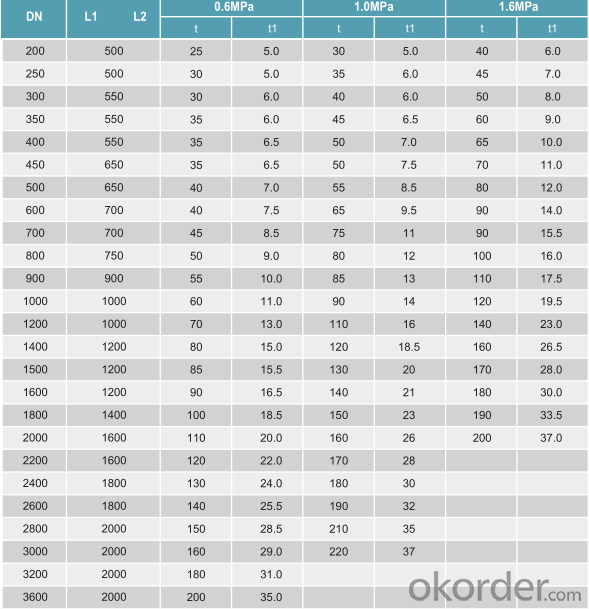

Model of GRP FRP Flange Adaptor sea water pipe series

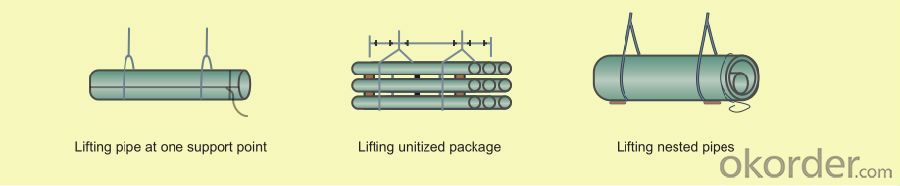

Unloading,Handling,Transportation and Storage of GRP pipe sea water pipe series

Unloading and Handling Pipes

Unloading the pipe is the responsibility of the customer. Be sure to maintain control of the pipe during unloading. Guide ropes attached to pipes or packages will enable easy manual control when lifting and handling. Do not drop, impact, or bump the pipe, particularly at pipe ends.

If at any time during handling or installation of the pipe, any damage such as a gouge, crack or facture occurs, the pipe should be repaired before the section is installed.

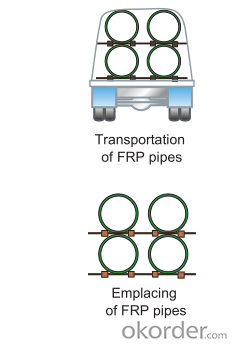

Transporting Pipes

Strap pipe to the vehicle over the support points using pliable straps or rope. Never use steel cables or chains without adequate padding to protect the pipe from abrasion. Bulges, flat areas or other abrupt changes of curvature are not permitted. Transport of pipes outside of these limitations may result in damage to the pipes.

Site Pipe Storage

It is generally advantageous to store pipe on flat timber to facilitate placement and removal of lifting slings

around the pipe.

When storing pipe directly on the ground, be sure that the area is relatively flat and free of rocks and other

potentially damaging debris. Placing the pipe on mounds of backfill material has been found to be an effective

way of site storing the pipe. All pipes should be chocked to prevent rolling in high winds.

FAQ of GRP FRP Flange Adaptor sea water pipe series

Q1: What’s the performance standards?

Lianzhong pipe is designed to meet all of these ASTM , AWWA, BS, DIN standards.

Q2: What’s the qualification testing for the products?

Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and DIN 16868 requirements

Q3: How long can I receive my goods?

A: Usually, we will deliver products within 20 days after the contract is signed. Delivery time is negotiable when necessary.

- Q:Designed to support FRP pipes, is it m or mm?

- Glass fiber reinforced plastic cable protection tube, a resin based, continuous glass fiber reinforced fabric as reinforced material, through computer control, winding process or pultrusion process of forming a pipeline. The glass steel production process, high strength, good toughness, electrical insulation, flame retardant, good heat resistance, can not deform, at 100 degrees high temperature corrosion resistance, erosion resistance and long service life, acid salt and various organic solvents with corrosive media, with a life span of 50 years. Applicable to a wide range of glass for cable laying underground steel cable protection tube, play a protective role, but also can be used for cable bridge, stone and of high demand

- Q:Glass fiber reinforced plastic sand pipe backfill 5m, how much kg pressure?

- In general, glass steel pressure refers to the internal pressure, the conveying pressure of water, and you said the backfill produces is the external pressure, often say that the stiffness parameter.

- Q:What are the main points for the installation of FRP ducts?

- Underground parking, commercial and residential buildings, shopping malls, civil air defense projects, office buildings and so on

- Q:How can I replace the valve on the water supply pipe?

- According to the position of the branch pipe, the position of the opening is reasonably determined, and the position of the socket of the glass steel pipe is avoided as far as possible, and a better position is selected in the middle of the pipe body;

- Q:What are FRP pipes?

- The glass steel base material and reinforcing material composition, because of different base material we have called GRE, some called GRP, the matrix material is generally resin reinforced material is glass fiber, adding other raw materials in the production process to obtain more excellent performance, such as adding graphite or carbon fiber can be obtained antistatic, using phenolic resin as matrix material, can obtain very high temperature resistant ability, can withstand instantaneous temperature of 3000 degrees celsius. The glass steel pipe in recent years in the shipbuilding industry is very popular and special attention, such as ship oil tankers, chemical tankers, offshore platform and ship ballast system, at the request of foreign shipowners in the use of glass steel pipes and fittings, its advantages in addition to the static electricity can guide, there are many advantages. Such as light weight, FRP pipe the same general size is only 35% of the weight of the steel pipe, is resistance to seawater corrosion, general steel and glass pipe manufacturers can promise: 50 years. Its disadvantage is that the pressure can bear the bottom and the modulus of elasticity is low. But it's enough in the ballast system. The GRE tube is better than the GRP tube in tensile strength and pressure resistance, so some people refer to the GRE tube as the high-pressure FRP pipe.

- Q:How can I make up the broken glass fiber?

- If you have to repair it, it is not impossible. Resin selection of good points, the general also line, as well as accelerators, curing agents, high-quality glass fiber cloth.

- Q:What are the advantages of glass fiber reinforced plastic sand pipe than HDPE pipe?

- Advantages of HDPE tubes:1. It is easy to form the closed anti-seepage system by butt welding and electrofusion welding. When laying along the trench, the excavation of the trench can be reduced and the amount of the fittings can be reduced.2 、 light weight and easy to install;3 、 strong abrasion resistance and excellent hydraulic performance, the buried pipeline can be protected without outer layer. The utility model can be applied to the earthquake and the soil subsidence area of the mining area, and can be laid on the bottom of the river by immersion method.4 、 chemical resistance, resistance to internal, external and microbiological corrosion, corrosion resistance, and health. The utility model is suitable for conveying acid and alkaline substances, conveying sewage, natural gas, gas and other substances;5, good environmental adaptability and frost resistance. It can be used in indoor and outdoor water supply pipelines.6, long service life, with more than almost 50 years of service life;7, easy to recycle

- Q:Are FRP pipes still developing?

- Glass steel complex (or perhaps not, but not absolutely continuous production mishap) manufacturing process, and China quality is not strictly controlled, low cost of pipeline as well as PVC and other engineering plastics, the high demand of the field of steel as reliable, is now used for chemical terminal treatment, city drainage etc..

- Q:How can FRP tanks be connected to steel tubes?

- Field bonding process is usually provided by glass fiber reinforced plastic manufacturers, if there is no way, I can provide some experience for reference, there is little information, experience only.

- Q:How to install FRP pipe correctly

- And glass fiber reinforced plastic parts (three, elbow, etc.) in general, the best way is on-site bonding, quality stability and convenience.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

GRP FRP Flange Adaptor Sea Water Pipe Series DN 600

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords