Patio Door Window Treatments

Patio Door Window Treatments Related Searches

Door Stops For Patio Doors Norco Patio Doors Patio Hooks Patio Blocks Sale Indoor Window Insulation Protective Paints Decorative Interior Doors Flat Roof Window Installation Roof Window Shades Indoor Window Insulator Classic Car Window Rubbers Insulating Paint Exterior Textured Wall Coatings Offset Patio Umbrellas On Sale Door Shutter Designs Texture Coating Exterior Walls Garden Decorations For Sale Replacement Window Sash Locks Front Entry Doors Repairing A Slate Roof Shop Front Awnings Yard Decorations For Sale Indoor Plantation Shutters Garden Awnings For Sale House Decorations For Sale Interior Composite Doors Attic Insulation Removal Insulating Aluminum Window Frames Glass Corner Protectors Sunbrella Patio Umbrellas Best PricePatio Door Window Treatments Supplier & Manufacturer from China

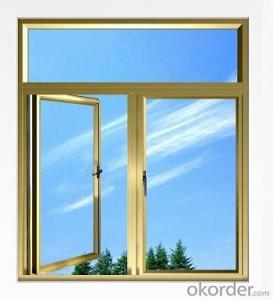

Patio Door Window Treatments encompass a variety of products designed to enhance the aesthetics and functionality of patio doors. These treatments come in different styles, materials, and designs, catering to various preferences and ensuring privacy, light control, and insulation. They are essential for homeowners looking to improve the ambiance and energy efficiency of their outdoor living spaces.Patio Door Window Treatments are widely used in residential and commercial settings, providing a range of benefits such as blocking harsh sunlight, reducing heat transfer, and increasing privacy. They can be applied to sliding glass doors, French doors, and large picture windows, making them versatile for various architectural styles. These treatments can also help in reducing noise pollution and protecting furniture from direct sunlight, ensuring the longevity and comfort of indoor spaces.

Okorder.com is a leading wholesale supplier of Patio Door Window Treatments, boasting a vast inventory that caters to diverse customer needs. With a commitment to quality and customer satisfaction, Okorder.com offers competitive prices and a wide selection of products, making it an ideal choice for those seeking to purchase Patio Door Window Treatments in bulk.

Hot Products