FRP Molded Grating /GRP Grating / FRP Grating with Great Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

- Aging Resistance

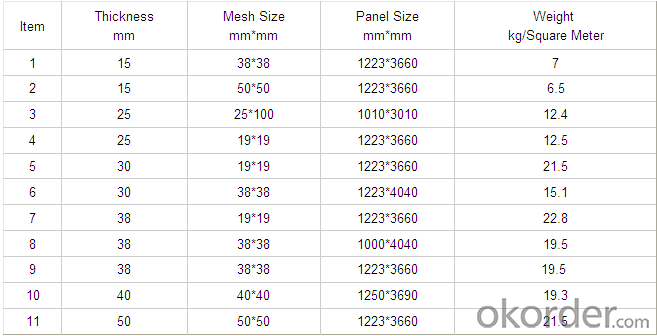

Specification

Advantage

coated with prevent aging layer

- high strength

long service life

easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

- All kinds of building maintenance section

FAQ

1. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

2. How is the package?

Usually, we arrange the standard out-package for exporting.

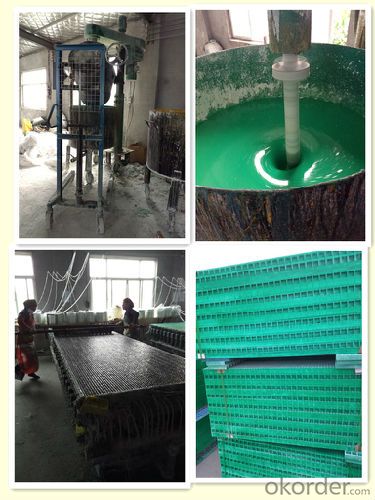

PROCESS

FACTORY

- Q:Are FRP pultrusion profiles resistant to UV degradation?

- Yes, FRP pultrusion profiles are generally resistant to UV degradation. The combination of the materials used in pultrusion, such as fiberglass and resin, provides inherent UV resistance, making them suitable for outdoor applications where exposure to sunlight is a concern. However, it is always recommended to consult the manufacturer's specifications and guidelines to ensure optimal UV protection and longevity.

- Q:What types of materials are commonly used in FRP pultrusion?

- The manufacturing process of FRP pultrusion involves pulling continuous fibers through a resin bath and then through a heated die, resulting in a composite material with high strength and stiffness. Different types of materials are commonly used in FRP pultrusion, depending on the specific application and desired properties. 1. Fibers: Fiberglass (glass-reinforced polymer) and carbon fibers are the most commonly used in FRP pultrusion. Fiberglass is cost-effective, lightweight, and offers good strength and corrosion resistance. Carbon fibers, on the other hand, are more expensive but provide exceptional strength, stiffness, and lightweight properties. 2. Resins: The resin matrix used in FRP pultrusion provides rigidity and protection against environmental factors. Polyester resin is the most commonly used due to its low cost, ease of handling, and good mechanical properties. Vinyl ester resin is another popular choice, offering improved chemical resistance and heat tolerance compared to polyester. Epoxy resin is used when high strength and durability are required. 3. Additives: The resin matrix can be enhanced with various additives to improve specific properties of the FRP pultruded product. UV stabilizers are commonly used to protect against ultraviolet degradation. Flame retardants can be added to increase fire resistance. Other additives like pigments, fillers, and mold release agents may also be used to achieve desired aesthetics and processing characteristics. By selecting the appropriate combination of fibers, resins, and additives, FRP pultrusion can produce a wide range of composite materials with tailored properties to meet specific application requirements. This versatility in material selection is one of the key advantages of FRP pultrusion, making it suitable for industries such as construction, infrastructure, aerospace, automotive, and marine.

- Q:Can FRP pultrusion profiles be used in the water treatment industry?

- Yes, FRP pultrusion profiles can be used in the water treatment industry. FRP (Fiber Reinforced Plastic) offers excellent corrosion resistance and durability, making it suitable for various applications in water treatment plants. FRP pultrusion profiles can be used in the construction of water tanks, pipes, pumps, and other equipment, providing a lightweight and high-strength alternative to traditional materials like steel. Additionally, FRP profiles are non-conductive and have low thermal conductivity, making them ideal for applications involving chemicals and extreme temperature variations commonly found in water treatment processes.

- Q:Are FRP pultrusion profiles resistant to nitric acid?

- FRP pultrusion profiles exhibit a general resistance to nitric acid. Nitric acid, being a potent oxidizing agent, has the ability to corrode various materials, including metals. However, the construction of FRP pultrusion profiles involves the use of composite materials that are specifically engineered to withstand the effects of corrosive substances, including nitric acid. The resilience of FRP pultrusion profiles against corrosion is attributed to the combination of reinforcing fibers, such as fiberglass or carbon fiber, and a resin matrix that securely binds these fibers together. The resin matrix, typically a thermosetting polymer like polyester or epoxy, forms a protective barrier that shields the profiles from corrosive substances. Nitric acid is renowned for its capacity to corrode and deteriorate metals. Nonetheless, FRP pultrusion profiles exhibit exceptional resistance to nitric acid due to the inert nature of the composite materials employed. The reinforcing fibers utilized in FRP profiles do not react with nitric acid, while the resin matrix effectively prevents the acid from reaching and corroding the fibers by acting as a barrier. It is essential to acknowledge that the specific resistance of FRP pultrusion profiles to nitric acid may vary depending on the precise composition of the composite materials utilized, as well as the concentration and temperature of the nitric acid. Therefore, it is always advisable to consult the manufacturer or supplier of FRP profiles to ensure their compatibility with nitric acid in specific applications.

- Q:Can FRP pultrusion profiles be used in wastewater or sewage treatment plants?

- FRP pultrusion profiles are applicable for use in wastewater or sewage treatment plants. These materials possess exceptional resistance against corrosion, making them an ideal option for environments that frequently encounter chemicals, moisture, and harsh conditions, such as wastewater treatment plants. Compared to conventional materials like steel or concrete, FRP pultrusion profiles offer numerous advantages. They are lightweight, yet incredibly sturdy and long-lasting, facilitating easy installation while maintaining resistance against damage or degradation over time. Additionally, FRP profiles possess non-conductive properties and display good thermal insulation, which can prove advantageous in specific applications within wastewater treatment plants. Moreover, FRP materials exhibit immunity to corrosion and rust, even when exposed to aggressive chemicals and gases commonly present in wastewater or sewage treatment plants. This corrosion resistance significantly prolongs the lifespan of FRP pultrusion profiles, thereby reducing the necessity for frequent maintenance and replacement. To summarize, owing to their corrosion resistance, durability, and other favorable properties, FRP pultrusion profiles are an appropriate choice for a variety of applications in wastewater or sewage treatment plants, including walkways, platforms, handrails, grating, and structural supports.

- Q:Are FRP pultrusion profiles resistant to moisture or humidity?

- FRP pultrusion profiles boast exceptional resistance to moisture and humidity. Through the pultrusion process, continuous fibers are thoroughly saturated with a polymer resin, resulting in a steadfast and enduring composite material. This composite possesses inherent moisture resistance, differing from conventional materials like wood or metal, as it does not absorb water. Moreover, FRP pultrusion profiles exhibit a minimal coefficient of thermal expansion, minimizing the likelihood of expansion or contraction in response to varying humidity levels. This moisture and humidity resistance render FRP pultrusion profiles suitable for a diverse array of applications, including outdoor structures, marine environments, and other areas prone to moisture.

- Q:Are FRP pultrusion profiles fire resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are fire resistant. The combination of the reinforcing fibers and the polymer matrix used in FRP pultrusion profiles provide them with excellent fire resistance properties. These profiles are manufactured using a process known as pultrusion, which involves impregnating reinforcing fibers such as fiberglass or carbon fiber with a thermosetting resin. This resin undergoes a curing process, resulting in a strong and durable composite material. One of the key advantages of FRP pultrusion profiles is their inherent fire resistance. The thermosetting resin used in the manufacturing process has properties that make it highly resistant to fire. When exposed to flames or high temperatures, the resin does not melt or burn easily, thus preventing the spread of fire. Additionally, the reinforcing fibers in FRP profiles also contribute to their fire resistance. Fiberglass, for example, is an inorganic material that does not burn. It acts as a barrier against heat transfer and helps to minimize the spread of flames. Furthermore, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating additional fire retardant additives or using specialized resin systems, the fire resistance of these profiles can be further enhanced. It is important to note that while FRP pultrusion profiles are fire resistant, their exact fire rating may vary depending on the specific composition and design. Therefore, it is essential to consult with manufacturers or suppliers who can provide detailed information about the fire resistance properties of their FRP pultrusion profiles.

- Q:Can FRP pultrusion profiles be used in the construction of wastewater treatment tanks?

- Indeed, wastewater treatment tanks can effectively utilize FRP pultrusion profiles. These profiles are renowned for their exceptional strength-to-weight ratio, resistance to corrosion, and longevity, making them an optimal option for harsh environments such as wastewater treatment facilities. To manufacture FRP pultrusion profiles, continuous fibers like glass or carbon are drawn through a resin bath and subsequently through a heated die to attain the desired shape. This process yields profiles with consistent cross-sections and outstanding mechanical properties. In the construction of wastewater treatment tanks, FRP pultrusion profiles can serve various purposes. They can function as structural components, like beams, columns, and bracing systems, offering the necessary strength and rigidity to support the tank structure. Additionally, FRP profiles can reinforce concrete structures, bolstering their durability and resistance against chemical attack from the wastewater. Moreover, FRP pultrusion profiles can be engineered to endure the corrosive impact of the chemicals and gases found in wastewater treatment tanks. Unlike conventional materials such as steel or concrete, FRP exhibits a high resistance to corrosion, guaranteeing an extended service life and reduced maintenance expenses. Furthermore, FRP profiles provide advantages in terms of installation and transportation. They are lightweight, enabling easier handling and diminished labor requirements during construction. The modular nature of FRP profiles also facilitates swift assembly and disassembly, simplifying maintenance and modifications. Overall, incorporating FRP pultrusion profiles in the construction of wastewater treatment tanks offers numerous benefits, including superior strength, corrosion resistance, durability, and ease of installation. These advantages render FRP a dependable and cost-effective choice for wastewater treatment facilities.

- Q:Can FRP pultrusion profiles be used in the construction of solar panel frames?

- Yes, FRP pultrusion profiles can be used in the construction of solar panel frames. FRP (Fiber Reinforced Polymer) pultrusion profiles have excellent strength-to-weight ratio, corrosion resistance, and durability, making them suitable for supporting and protecting solar panels. Additionally, FRP profiles can be customized to meet specific design requirements, providing flexibility in constructing solar panel frames.

- Q:Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical manufacturing?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to chemicals used in pharmaceutical manufacturing. FRP profiles are made by impregnating fibers with a resin matrix, typically polyester or vinyl ester, which provides excellent chemical resistance. These profiles are designed to withstand exposure to a wide range of chemicals including acids, alkalis, solvents, and various cleaning agents commonly used in pharmaceutical manufacturing processes. The combination of the fiber reinforcement and the chemical-resistant resin matrix makes FRP pultrusion profiles an ideal choice for applications where exposure to aggressive chemicals is a concern. Unlike traditional materials like steel or wood, FRP profiles do not corrode or react chemically with the substances they come into contact with. Furthermore, FRP pultrusion profiles offer several other advantages for pharmaceutical manufacturing applications. They have exceptional strength-to-weight ratio, are non-conductive, and have high mechanical resistance. Additionally, FRP is a non-porous material, preventing the absorption or release of chemicals, which is crucial for maintaining strict hygiene and avoiding contamination in pharmaceutical processes. Overall, FRP pultrusion profiles are a reliable and durable choice for pharmaceutical manufacturing environments, providing excellent resistance to the chemicals commonly used in these processes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP Molded Grating /GRP Grating / FRP Grating with Great Shape

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords