Prepainted Galvanized Steel

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

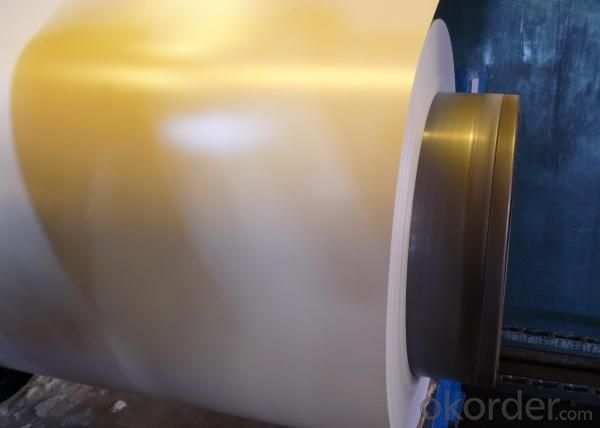

Prepainted Galvanized Steel

With galvanized steel as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Brand Name: HBSTEEL

Specifications OfPrepainted Galvanized Steel

|

Thickness 0.20-1.2mm (BMT) Width 600-1250mm |

|

Zinc Coating 100-275g/m2 |

|

Color According to RAL color fan or as per request |

|

Internal Diameter 508mm or 610mm |

|

Coil Weight 3-6MT |

|

Quality Commercial and structural quality |

|

Paint Polyester paint for topside, epoxy for reverse |

|

Standard JIS G 3312, ASTM A755M, EN 10169 |

|

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD,S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

|

C |

Si |

Mn |

P |

|

0.04-0.06% |

0.01-0.03% |

0.18-0.22% |

0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

|

Yield Strength |

(Mpa) 280-320 |

|

Tensile Strength |

(Mpa) 340-390 |

|

Elongation |

20%-30% |

|

Reverse Impact |

9J |

|

T-bending |

≥2T |

|

Pencil Hardness |

≥2H |

|

Duration Of Salt Spray Test |

500 H |

|

Bending At 180 Degree |

No crack, purling and fraction |

Applications OfPrepainted Galvanized Steel

It can be widely used in transportation, light industry, civil usage and farming. It is also the perfect building material in construction for making steel roofing,insulation panel, corrugate sheet, facade wall,shutters,T-bar and home appliance.

Packaging & Delivery Of Prepainted Galvanized Steel

The packing of coils consists of anti-damp paper, PVC film, hardboard paper, steel box, strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye to the side) or wooden pallets(eye to the sky).

Production Flow Of Prepainted Galvanized Steel

Production flow of hot sell prepainted galvanized steel include dual uncoiler,stitcher, bridles, entry accumulater, degreasing & chemical section, prime coater, prime oven, prime water quench, finish coating, finish back coater, finish oven, finish water quench, exit accumulater and recoiler.

- Q: How does steel sheet metal fabrication work?

- Steel sheet metal fabrication involves the process of shaping and manipulating steel sheets into desired forms and structures using various techniques such as cutting, bending, and assembling. This is typically done through the use of specialized machinery and tools, such as laser cutters, press brakes, and welders. The steel sheets are first cut into the required shape, either manually or through automated processes. Then, they are bent or formed using press brakes to achieve the desired angles or curves. Finally, the individual parts are assembled together through welding, fastening, or other joining methods, resulting in a finished steel sheet metal product.

- Q: How are steel coils used in manufacturing processes?

- Steel coils are used in manufacturing processes as a primary material for various applications such as construction, automotive, appliances, and machinery. These coils are typically unwound and processed through different machines to be shaped, cut, and formed into the desired products. The versatility and strength of steel coils make them an essential component in many manufacturing industries.

- Q: What are the different types of steel wire ropes and their uses?

- There are several different types of steel wire ropes, including galvanized, stainless steel, and vinyl-coated ropes. Galvanized steel wire ropes are commonly used in outdoor applications as they have a protective zinc coating that helps prevent rust and corrosion. Stainless steel wire ropes are highly resistant to corrosion and are ideal for marine, industrial, and food processing applications. Vinyl-coated steel wire ropes are often used in gym equipment, playgrounds, and other applications where a smooth and protective covering is required to prevent damage. Each type of steel wire rope has its own specific uses and benefits depending on the intended application.

- Q: How are steel products used in the construction of government buildings and administrative centers?

- Steel products are commonly used in the construction of government buildings and administrative centers due to their durability, strength, and versatility. Steel beams and columns provide structural support, ensuring the stability of the building. Steel roofing and cladding offer protection against external elements and enhance the building's energy efficiency. Additionally, steel is often used for doors, windows, and interior partitions, providing security and flexibility in design. Overall, steel products play a critical role in constructing government buildings and administrative centers by contributing to their longevity, safety, and functionality.

- Q: What are the different types of steel channels?

- There are several different types of steel channels, including C channels, U channels, and J channels. Each type has its own unique shape and dimensions, making them suitable for various applications in construction, manufacturing, and structural engineering.

- Q: What are the different grades of steel?

- There are several different grades of steel, classified based on their composition and properties. Some common grades include mild steel, stainless steel, high-strength low-alloy steel, and tool steel. Each grade is designed for specific applications and offers varying levels of strength, corrosion resistance, hardness, and other desirable characteristics.

- Q: What are the different types of steel chains and their uses in lifting equipment?

- There are several types of steel chains used in lifting equipment, each with its own specific uses. Some common types include: 1. Grade 80 Chains: These chains are made from alloy steel and are known for their high strength and durability. They are commonly used in heavy-duty lifting applications such as construction and mining. 2. Grade 100 Chains: Similar to Grade 80 chains, Grade 100 chains offer even higher strength and are suitable for more demanding lifting tasks. They are often used in applications that require extra safety measures, such as overhead lifting. 3. Stainless Steel Chains: These chains are made from corrosion-resistant stainless steel, making them ideal for lifting equipment used in environments with high humidity or exposure to chemicals. They are commonly used in marine, food processing, and pharmaceutical industries. 4. Proof Coil Chains: These chains are made from low-carbon steel and are designed for general-purpose lifting applications. They are widely used in industries such as agriculture, warehousing, and manufacturing. 5. Transport Chains: Also made from low-carbon steel, transport chains are specifically designed for securing and transporting heavy loads. They are commonly used in the transportation industry for securing cargo on trucks, trailers, and flatbeds. Overall, the choice of steel chain depends on the specific lifting application, load capacity requirements, and environmental conditions, ensuring the safety and efficiency of the lifting equipment.

- Q: What are the different types of steel fencing materials?

- There are several types of steel fencing materials available, including wrought iron, galvanized steel, aluminum, and stainless steel. Wrought iron is known for its durability and ornate designs, while galvanized steel offers excellent corrosion resistance. Aluminum is lightweight and low-maintenance, making it a popular choice for residential fencing. Stainless steel is highly resistant to rust and offers a sleek, modern look.

- Q: What are the different types of steel pipes and their uses?

- There are several types of steel pipes, including seamless, welded, galvanized, and ductile iron pipes. Seamless pipes are commonly used in high-pressure applications, such as oil and gas pipelines, due to their strength and ability to withstand extreme conditions. Welded pipes, on the other hand, are more cost-effective and suitable for less demanding applications like plumbing and structural support. Galvanized pipes are coated with zinc to prevent corrosion and are often used in outdoor plumbing systems. Ductile iron pipes, known for their durability and flexibility, are mainly used in water distribution systems and underground applications.

- Q: What are the different types of steel forgings and castings available?

- There are several different types of steel forgings and castings available, including open die forgings, closed die forgings, rolled ring forgings, investment castings, sand castings, and shell mold castings. These different processes result in steel components with varying shapes, sizes, strengths, and surface finishes, allowing for a wide range of applications in industries such as automotive, aerospace, construction, and manufacturing.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2008 |

| Annual Output Value | |

| Main Markets | Asia |

| Company Certifications | ISO9001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin Port |

| Export Percentage | 50% |

| No.of Employees in Trade Department | 50 |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Over 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Average |

Send your message to us

Prepainted Galvanized Steel

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50mt m.t.

- Supply Capability:

- 5000 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords