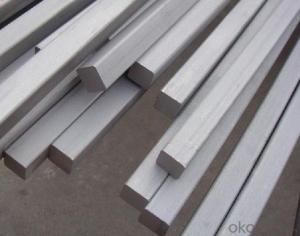

3sp,5sp chrome alloy square steel billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

square steel billets 3sp & 5sp grade

Specifications

square steel billets

1)We procure world class quality steel billets which meets the specific requirements of the clients

The Billets produced by the company can be broadly divided into three main types i.e.

1 M.S. Billets

2 CRS Billets

3 Special Alloy Billets

M.S. Billets are used for rolling of TMT Re-Bars of Fe415 and Fe500 Grade and various other structural steel products.

CRS Billets are used fro rolling of CRS TMT Re-Bars.

Special Alloy Billets are used for rolling of any special grade TMT Re-Bars like Earthquake resistant TMT Re-Bars and for special grade structural steel products.

The following are the sizes of Billets available with Shyam Steel Industries Ltd.:

100 X 100

125 X 125

150 X 150

Physical Properties:

Description | As per IS 2830 | Shyam Billets |

Bend (max.) | 5 mm per meter | >= 5 mm per meter |

Carbon (max.) | 3mm per meter | >= 3 mm per meter |

Length | 3 mt - 13 mt | 3 mt - 9 mt |

Chemical Properties:

Ladle Analysis: | ||

Designation | Carbon | Manganese |

C15 | 0.12-0.18 | 0.30-0.60 |

C18 | 0.15-0.21 | 0.30-0.60 |

C20 | 0.17-0.23 | 0.30-0.60 |

C15 MMn | 0.12-0.18 | 0.60-1.00 |

C18 MMn | 0.15-0.21 | 0.60-1.00 |

C20 MMn | 0.17-0.23 | 0.60-1.00 |

C15 HMn | 0.12-0.18 | 1.00-1.50 |

C18 HMn | 0.15-0.21 | 1.00-1.50 |

C20 HMn | 0.17-0.23 | 1.00-1.50 |

Billets of different designations are manufactured in three different grades namely A, B, C having sulphur, phosphorous content (on ladle analysis) and carbon equivalent as follows:

Chemical Analysis: | |||

Grade | Sulphur | Phosphorous | Carbon Equivalent (CE)1 |

Max | Max | Max | |

A | 0.05 | 0.05 | 0.42 |

B | 0.045 | 0.045 | 0.41 |

C | 0.04 | 0.04 | 0.39 |

The Detail of Product

Name: | steel billets |

LENGTH: | 6 meter to 12 meter (+ 50mm) |

Size: | 100*100, 120*120, 150*150, 200*200 |

Grade: | 3SP,5SP,Q235,20MnSi. |

Shape: | Square, Round |

Technique: | Hot-Rolled |

Standard: | ASTM/GB |

BENDING | No more than 5mm in 1 meter |

ANGULAR TWIST | No more than 1 degree per meter and not more than 6 degree over 12 meter length. |

Chemical composition | C, Si, Mn, P, S, N, etc |

Chemical Properties

Size | 60*60/90*90/100*100/120*120/150*150 |

Length | 6000mm-12000mm |

Standard | GB |

Applicaton | To produce bars or other applications |

Grade | Q195/Q235/Q275/3SP/5SP/20MnSi |

Packing terms | TT/LC |

Package | Mill's standard packing or as client's requirment |

Delivery time | Within 10-30 days after receiving the deposit or LC |

Chemical Comosition

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

- Q: How do steel products contribute to the construction of theme-based amusement parks?

- Steel products play a crucial role in the construction of theme-based amusement parks by providing structural support, safety, and aesthetic appeal. Steel is widely used in the fabrication of roller coasters, water slides, and other thrill rides, ensuring their stability and durability. Additionally, steel frameworks and trusses are employed to construct large-scale structures such as theme park entrances, iconic landmarks, and indoor pavilions. The versatility and strength of steel enable designers to create intricate and gravity-defying structures, enhancing the overall experience and visual appeal of theme parks.

- Q: How is steel different from iron?

- Steel is different from iron primarily because of its carbon content. While iron is a pure metal with a relatively low carbon content, steel is an alloy of iron and carbon, usually with a carbon content ranging from 0.2% to 2.1%. This carbon content gives steel its enhanced strength, hardness, and durability compared to iron. Steel also possesses better corrosion resistance and can be easily manipulated into various shapes and forms, making it more versatile for a wide range of applications.

- Q: How are steel sheets used in the manufacturing of solar panels?

- Steel sheets are used in the manufacturing of solar panels as a base material for the panel structure. They provide strength and durability to support the various components of the solar panel, such as the photovoltaic cells, glass cover, and electrical connections. The steel sheets also aid in protecting the internal components from external elements and provide a stable platform for installation.

- Q: What are the different grades of steel and their respective applications?

- There are several grades of steel, each with unique properties and applications. Some common grades include carbon steel, which is widely used in construction and manufacturing; stainless steel, which is resistant to corrosion and commonly used in kitchen appliances and medical equipment; tool steel, which is known for its high hardness and used in cutting tools; and alloy steel, which contains different elements to enhance specific properties and is used in automotive and aerospace industries.

- Q: How are steel tubes used in the fabrication of hydraulic systems?

- Steel tubes are commonly used in the fabrication of hydraulic systems due to their strength, durability, and resistance to high pressure. These tubes serve as conduits for hydraulic fluid, allowing it to flow efficiently and safely between components such as pumps, cylinders, and valves. Steel tubes also provide stability and support, ensuring the system operates smoothly and reliably.

- Q: What are the safety precautions to be taken while handling steel products?

- When handling steel products, it is important to follow several safety precautions. These include wearing appropriate personal protective equipment, such as gloves and safety glasses, to protect against cuts and eye injuries. It is also crucial to use proper lifting techniques and equipment, as steel products can be heavy and pose a risk of strain or muscle injury. Additionally, ensuring a clean and organized workspace can help prevent slips, trips, and falls. Finally, being aware of potential hazards, such as sharp edges or falling objects, and practicing caution and awareness when handling steel products can help minimize the risk of accidents and injuries.

- Q: What is the role of steel in the manufacturing of appliances?

- The role of steel in the manufacturing of appliances is crucial as it provides strength, durability, and resistance to heat and corrosion. Steel is used in various components of appliances, such as the outer shells, frames, and internal structures, to ensure they can withstand the rigors of everyday use and maintain their integrity over time. Additionally, steel's malleability allows for the creation of complex shapes and designs, making it a versatile material for appliance manufacturing.

- Q: What are the different types of steel bolts and their uses?

- There are various types of steel bolts, each designed for specific applications. Some common types include hex bolts, carriage bolts, anchor bolts, and eye bolts. Hex bolts are the most versatile and widely used, typically for general fastening purposes. Carriage bolts have a round head and are commonly used in wood-to-wood connections. Anchor bolts are used to secure structures to concrete or masonry. Eye bolts have a looped head and are ideal for lifting heavy objects. The choice of bolt depends on the specific requirements of the project and the type of materials being fastened.

- Q: What are the different types of steel products used in the manufacturing of cleaning equipment?

- There are several different types of steel products commonly used in the manufacturing of cleaning equipment. Some of these include stainless steel, which is highly resistant to corrosion and staining, making it suitable for applications where cleanliness is essential. Carbon steel is another commonly used type, known for its strength and durability. It is often used for heavy-duty cleaning equipment that requires a strong and robust construction. Additionally, galvanized steel can be used for cleaning equipment exposed to moisture or harsh environments, as it is coated with a protective layer that prevents rusting.

- Q: How do steel products contribute to the construction of theme-based water parks?

- Steel products play a crucial role in the construction of theme-based water parks. They are used in various structural and architectural components, such as roller coaster tracks, water slides, support beams, and framework for buildings and attractions. The strength and durability of steel ensure the safety and stability of these structures, allowing for thrilling rides and unique water features. Additionally, steel can be shaped and molded into intricate designs, enhancing the aesthetic appeal of the park and creating a visually captivating experience for visitors.

Send your message to us

3sp,5sp chrome alloy square steel billet

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords