Mild Steel Billet for Selling in 3SP,4SP,5SP

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Mild Steel Billet for Selling in 3SP,4SP,5SP

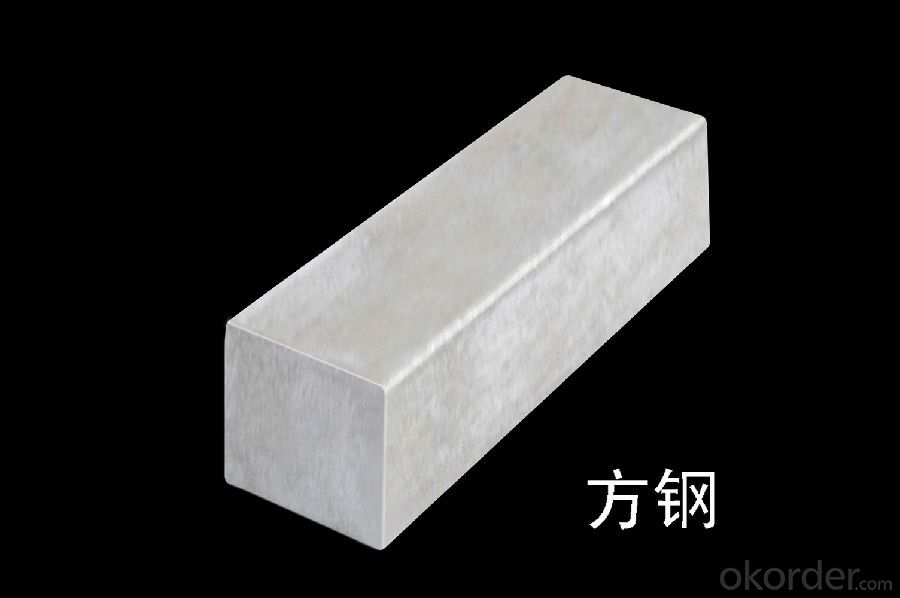

Structure of Mild Steel Billet

Grade: mild steel 3sp 4sp 5sp

Dimensions: 100mmx100mm

Standard: AISI, ASTM, BS, DIN, GB, JIS, steel billet

Steel billet length:: 3m-12m

billet steel grade:: 3sp 4sp 5sp q235 q195 q255 q275 20mnsi

Main Features of Mild Steel Billet

Type : | Square steel billet |

Steel Grade: | 3sp 5sp q195 q235 q255 q275 20mnsi ,astm a615 gr.60 |

Size: | 60x60mm-150x150mm |

Length: | 2m-12m . |

Processing: | Hot rolled continous cast. |

Application: | Wire rod , rod , deformed bars , profile steel , mechine parts , and steel mould ect . |

Packing: | Loose Packing. |

MOQ: | 1000Tons |

Delivery Time: | 25days |

Payment: | T/T , L/C,West Union , Cash . |

Trade term: | FOB, CFR, CIF ,EXW. |

Trans term: | FIO ,FILO ,FLT. |

Datas and Detail Information for Mild Steel Billet

Steel billet | |||||

Steel Grade | C(%) | Mn(%) | Si(%) | P(%) | S(%) |

Q235 | ≤0.20 | ≤1.40 | ≤0.35 | ≤0.045 | ≤0.045 |

Q275 | ≤0.22 | ≤1.50 | ≤0.35 | ≤0.045 | ≤0.045 |

20MnSi | 0.17-0.25 | 1.20-1.60 | 0.40-0.80 | ≤0.050 | ≤0.050 |

3SP | 0.18-0.22 | 0.60-0.85 | 0.05-0.30 | ≤ 0.040 | ≤0.050 |

5SP | 0.28-0.37 | 0.80-1.00 | 0.15-0.30 | ≤ 0.040 | ≤0.050 |

Above list some chemical components were other customers requested , pls let us know what steel grade you required?

we can produce according to your needed.

FAQ

Q:Why should choose us?

A:Stable quality ----continous casting hot rolled production techenic, strictly quality control system.

Lower price -------Not the cheapest but the lowest price at the same quality .

Good service -----Satisfactory service within 24hours.

Delivery time ------15-25days for the mass production .

Discount---------------discount base on monthly large quantity purchase in long term.

Pictures:

- Q: What is the primary purpose of steel pipes?

- The primary purpose of steel pipes is to transport fluids and gases, such as water, oil, and natural gas, over long distances in a safe and efficient manner.

- Q: How much is the wall thickness standard of building 48?

- According to the "construction of fastener type steel pipe scaffold safety technical specifications JGJ130-2011" stipulates that the specification of steel pipe should be Phi 48.3 * 3.6, that is, wall thickness is 3.6mm.

- Q: Can steel pipes be used for underground fuel pipelines?

- Yes, steel pipes can be used for underground fuel pipelines. Steel pipes are commonly used for various types of pipelines due to their durability, strength, and resistance to corrosion. When it comes to underground fuel pipelines, steel pipes are a popular choice due to their ability to withstand high pressure and temperature fluctuations. Additionally, steel pipes provide excellent protection against external elements, such as soil movement or chemical reactions, ensuring the safety and integrity of the fuel transportation system. Proper insulation and coating can further enhance the corrosion resistance of steel pipes, making them a reliable option for underground fuel pipelines.

- Q: What are the factors that affect the lifespan of steel pipes in different environments?

- The factors that affect the lifespan of steel pipes in different environments include the presence of corrosive substances, such as chemicals or saltwater, which can corrode the steel and lead to degradation over time. Other factors include temperature fluctuations, which can cause expansion and contraction of the steel, leading to stress and potential cracking. The quality of the protective coating on the pipes also plays a role, as a strong and durable coating can provide better resistance against corrosion and prolong the lifespan of the pipes. Additionally, the maintenance and regular inspection of the pipes, including cleaning and repairs, can help identify and address any issues early on, preventing further damage and extending their lifespan.

- Q: How are steel pipes used in the agriculture sector?

- Steel pipes are commonly used in the agriculture sector for various purposes such as irrigation, drainage systems, and the transportation of water, chemicals, and fertilizers. They are also used in the construction of greenhouse structures and livestock enclosures, providing durability and strength to withstand harsh agricultural environments. Additionally, steel pipes are employed for post and pole applications, supporting fences and gates on farms.

- Q: How are steel pipes protected against ultraviolet (UV) radiation?

- Steel pipes can be protected against ultraviolet (UV) radiation through the application of coatings or paints that act as a barrier between the pipe surface and the UV rays. These coatings are specifically designed to resist the damaging effects of UV radiation, such as fading, chalking, or degradation of the steel material. One common method of protection is the use of UV-resistant paints or polymeric coatings that contain special additives or pigments that reflect or absorb UV rays. These coatings not only shield the steel from UV radiation but also provide an additional layer of corrosion protection, extending the lifespan of the pipes. Another method used for UV protection is the application of thermal insulation materials. These insulating materials, such as foam or coatings with reflective properties, are capable of reducing the impact of UV radiation on the steel pipes. They act as a shield, preventing direct exposure to the UV rays and minimizing the potential damage caused by prolonged exposure. It is important to note that the choice of UV protection method depends on various factors, including the specific application, environmental conditions, and the required durability of the steel pipes. Consulting with experts in the field can help determine the most suitable UV protection solution for a particular project or application.

- Q: What is the difference between hot-finished and cold-finished steel pipes?

- Hot-finished steel pipes are produced by heating the steel to a high temperature and then passing it through a series of rollers to give it the desired shape and size. This process results in a smooth surface finish and improved mechanical properties. On the other hand, cold-finished steel pipes are produced by cold drawing the steel through a die, resulting in a smaller diameter and improved dimensional accuracy. Cold-finished pipes have a smoother surface finish and tighter tolerances compared to hot-finished pipes.

- Q: How are steel pipes used in the manufacturing of wind turbines?

- Steel pipes are used in the manufacturing of wind turbines primarily for constructing the tower, which provides structural support and stability to the turbine. These steel pipes are typically large in diameter to withstand the strong winds and carry the weight of the turbine components. Additionally, steel pipes are also utilized for the transmission of electrical cables within the turbine, ensuring efficient power generation.

- Q: What are the factors to consider when selecting the right steel pipe for a specific application?

- There are several factors to consider when choosing the appropriate steel pipe for a particular application. These factors encompass: 1. Compatibility with materials: Ensuring that the steel pipe is compatible with the substance it will transport or contain is crucial. Different materials may necessitate specific types of steel pipes to prevent corrosion or contamination. 2. Pressure and temperature requirements: The pressure and temperature conditions that the steel pipe will face should be taken into account. This will determine the necessary thickness and strength of the pipe to ensure it can withstand the intended operating conditions. 3. Size and dimensions: Selecting the size and dimensions of the steel pipe should be based on the flow rate, volume, and available installation space. It is vital to choose a pipe with the appropriate diameter and wall thickness to prevent flow restrictions or leaks. 4. Environmental conditions: The environment in which the steel pipe will be installed must be considered. Factors such as exposure to moisture, chemicals, or extreme temperatures may necessitate the use of specific coatings or materials to enhance the longevity and durability of the pipe. 5. Cost considerations: The cost of the steel pipe and its installation should be taken into account. Striking a balance between desired quality and available budget is essential to ensure the most cost-effective solution. 6. Regulatory compliance: Depending on the application, there may be specific industry regulations or standards that must be adhered to. Choosing a steel pipe that meets these requirements is important to ensure compliance and avoid any legal or safety issues. 7. Maintenance and lifespan: The maintenance requirements and expected lifespan of the steel pipe should also be considered. Some applications may require regular inspections or replacements, while others may require a more durable and long-lasting pipe. By carefully considering these factors, it is possible to select the appropriate steel pipe for a specific application that meets the desired performance, durability, and safety requirements.

- Q: How are steel pipes used in bridge construction?

- Steel pipes are commonly used in bridge construction for various purposes. They are often used as piles to provide structural support to the bridge foundation, ensuring stability against soil movement and water pressure. Additionally, steel pipes are used as structural components in the bridge's superstructure, such as for trusses and beams, due to their high strength and durability. Steel pipes also play a crucial role in carrying utilities, such as water and gas pipelines, across the bridge. Overall, steel pipes are an essential element in bridge construction, providing strength, stability, and functionality to the structure.

Send your message to us

Mild Steel Billet for Selling in 3SP,4SP,5SP

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords