All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

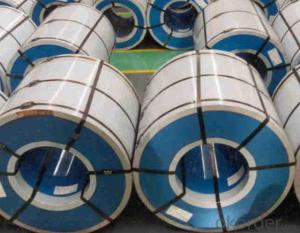

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does cold-rolled steel perform in high-temperature environments?

Cold-rolled steel generally performs well in high-temperature environments due to its ability to retain strength and resist deformation. However, its resistance to oxidation and corrosion may be compromised at extremely high temperatures, making it less suitable for prolonged exposure in such conditions.

How is cold-rolled steel typically transported and stored?

Cold-rolled steel is typically transported and stored in flatbed trucks or shipping containers to ensure its safety during transportation. Once it arrives at the storage facility, it is stored indoors in a controlled environment to protect it from moisture, extreme temperatures, and other elements that can cause corrosion or damage. Additionally, the steel is often stacked in neat piles or placed on racks to maximize space and facilitate easy access for retrieval when needed.

What are the key differences between cold-rolled and cold-forged steel?

The key differences between cold-rolled and cold-forged steel lie in their manufacturing processes and resulting properties. Cold-rolled steel undergoes a process where it is rolled at room temperature to achieve a desired thickness, resulting in improved dimensional accuracy and a smooth surface finish. On the other hand, cold-forged steel is shaped through a compression process where it is subjected to high pressure and force, resulting in increased strength and toughness. While cold-rolled steel is more suitable for applications requiring precise dimensions and a polished appearance, cold-forged steel is preferred for applications that demand greater strength and durability.

Wholesale Cold Rolled Steel from supplier in Liberia

We guarantee prompt delivery, competitive pricing, and exceptional customer satisfaction. Contact us today to discuss your Cold Rolled Steel requirements and let us provide you with the best solutions for your business.