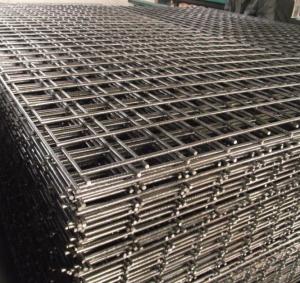

Steel Bar Welded Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Description:

Steel mesh and said: welded steel mesh, welded mesh, welded wire mesh, welded wire mesh, steel mesh, etc.. Is the longitudinal and transverse reinforcement of a certain distance, and each other into a right angle, all the cross points are welded together in the network.

Steel mesh used in industrial and civil buildings beam floor, roof, wall, concrete pavement, bridge deck pavement, airport runway, tunnel lining, box culvert, dock floor, prefabricated units, and other fields.

2. Product Characteristic:

1. Significantly improve the engineering quality of steel

2. Obviously improve the construction speed

3. Reinforced concrete anti cracking ability

4. Have better comprehensive economic benefits

1. QUALITY:

GB/T1499.3-2002

AS/NZS 4671:2001

BS 4483︰2005

A185-02

2. RAW MATERIAL:

A.cold-rolled deformed bar GRADE:CRB550

B.hot-rolled deformed bar GRADE:HRB400

3.Specification :

size | 4-16 | |||

Reinforcement spacing(mm) | Portrait | 100、150、200、300 | ||

Landscape | 100-400 | |||

Mechanical and process property | Meet “GB/T1499.3-2002” standard;AS/NZS 4671; 2001,BS 4483:2005,A185-02 | |||

Mesh size(mm) | wide | max 3300,By transportation limited:trucks≦2350;train≦2750 |

long | ≦12000 |

4. Reference Picture:

- Q:im installing a line out converter on my 2006 avalnche and i need to know which wires go to the right and left rear speakers so i can install it, do you know which is wire goes to where?

- Avalanche Diagram

- Q:Does anyone have a schematic?

- on the wires it should tell you want the wires are four you should have a red wire black wire.the red is live wire and the back wire is earth wire.and the four you got left is speaker wires

- Q:wire diagram and manual

- a small boats wiring cant be very complicated. If you're needing to replace it get a book called Small Boat Wiring or a similar. If you're trying to find a fault with existing wiring simply trace the existing wires remake all the connections as you go. I suggest you pull the lot out redo it properly. Except for the electric start you dont need super heavy cabling for a small boat. Tinned multi strand wire with a core diameter of about 2 mm is fine. Get a roll of red one of black ( or use red/black figure 8 cable) From the battery fit a service fuse of about 15 - 20 amp in line with the positive cable right near the battery. Use only properly crimped screwed or soldered connections. If the connection is ever likely to get wet then cover the connection with a piece of heatshrink tubing with a good smear of neutral cure silicone inside it. The silicone should squeeze out both ends of the tube when you shrink it. Dont make any joints mid run ( never in the bilges). Make sure the wiring is secured where it is out of the way is neat. Support the wire near the connections. Run from the switch panel to each item as a separate circuit, dont daisy chain. Give each item its own cable including the return (black wire) brought back to the panel. Be neat make a permanent record of what you've done. Fuse each circuit with a fuse rated about 50% above what that item should draw. Always carry plenty of spare fuses.

- Q:Theirs a green ground wire, a white neutral wire and for some reason 3 black wires.

- If the ceiling fan has three speeds, those would be wired to a 3 position switch as low, medium and high. Normally the wires would be labeled if they use the same color. If they aren't tagged, and you want to put in a speed control switch, you'll need to experiment; either at the fixture, or just wire them down to the wall switch and make your temporary connections there to see which wires go with which speeds (then TAG them!).

- Q:i have some ikea wall lights that are wired to plug but i would like to wire them into exsiting wall points. Is this possibleSandra

- yes as long as any fuses that you remove along with the plug are equalled by fuses in the spur outlet you are using, and the wires are secured so they cannot be pulled down , the plug is the weak point in the circuit if the wire snags it pulls the plug out if you secure the wire the weak point is most likely the wire if it breaks you will have a live wire dangling about so if its not secure its dangerous

- Q:does bigger power, ground, speaker wires give more power 2 the amplifier?

- Bigger power and ground wires will help, up to a point. If your wires are already big enough that you don't have a significant voltage drop between the battery and the amp, then bigger cables won't help anything.

- Q:I have a very old house. I was unhooking the fluorescent light in our kitchen to put a round ceiling light in and the old fluorescent light was plugged into the ceiling (like any regular two pronged electrical plug). How do I wire the ground wire, the line voltage wire, and the neutral wire from the new light so I can plug it into the plug in my ceiling?

- Your question was answered here except what to do with the ground and it sounds like you dint have one so just coil it and maybe some day when you rewire you can hook it up

- Q:Hi,I have an issue with wiring in house. This is in Paris, France. I will share a foto so you can have a clearer picture what my question is.

- Got a meter? On the output side Wht/Grn = ground Brown = 'Hot' (230 V.) Blue = Neutral Test out what you've got in the French outlet box.

- Q:dont know which wires are which, trying to install after market stereo

- 2002 Nissan Frontier Stereo Wiring Diagram Car Radio Battery Constant 12v+ Wire: Pink Car Radio Accessory Switched 12v+ Wire: Blue Car Radio Ground Wire: Gray or Chassis Car Radio Illumination Wire: Red/Blue Car Stereo Dimmer Wire: Red/Yellow Car Stereo Antenna Trigger: N/A Car Stereo Amp Trigger Wire: N/A Car Stereo Amplifier Location: N/A Car Audio Front Speakers Size: N/A Car Audio Front Speakers Location: N/A Left Front Speaker Positive Wire (+): Pink Left Front Speaker Negative Wire (-): Blue Right Front Speaker Positive Wire (+): White Right Front Speaker Negative Wire (-): Black Car Audio Rear Speakers Size: N/A Car Audio Rear Speakers Location: N/A Left Rear Speaker Positive Wire (+): Light Green Left Rear Speaker Negative Wire (-): Violet Right Rear Speaker Positive Wire (+): Blue Right Rear Speaker Negative Wire (-): Pink

- Q:ok so the passenger side back floorboard was getting wet and i believe the water to have corroded the wiring to my radio i've taken care of the water problem and know how to reconfigure the wiring but do i need to be worried about the security system while tinkering with the wiring see as how sensitive the security in these cars are i figured id check and see what you guys have to say about this pls also give resources as to how you know

- you can go to best buy and order a new wiring harness, for your car. all you do is plug it in, to your car and SOUND system and alarm

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Bar Welded Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords