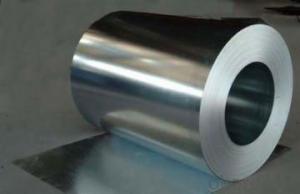

Aluzinc coated galvanized steel sheet AFP SGCL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Galvalume should not be used on, in, or around concrete or mortar. Concrete and mortar are highly

alkaline environments. Bare Galvalume and painted Galvalume sheets suffer rapid corrosion when

in contact with mortar and concrete. Bare Galvanized and painted Galvanized perform better in this

type of environment.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

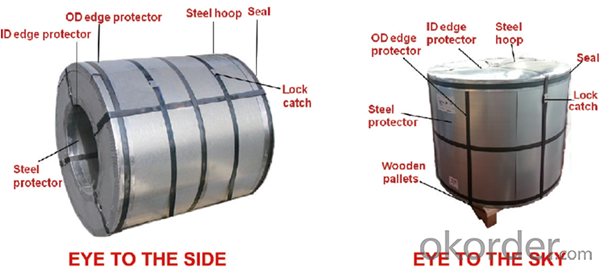

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: Are the steel sheets available in different thickness tolerances?

- Yes, steel sheets are available in different thickness tolerances.

- Q: What is the difference between the zinc plated color guide and the profiled steel sheet?

- The difference between the zinc plated color guide plate and the profiled steel plate is as follows:1, plated aluminum plate is pure aluminum 99%, and aluminum zinc is generally divided into 5% zinc plating and 55% aluminum zinc.2, zinc plating in zinc plating on the basis of the development of slowly, and 5% and 55% refers to the aluminum content.

- Q: What are the different types of steel sheet finishes for automotive applications?

- Automotive applications commonly utilize various types of steel sheet finishes. These finishes are applied to the surface of the steel sheet for the purpose of enhancing its appearance, durability, and resistance to corrosion. The mill finish, for instance, is a natural finish that the steel sheet attains after undergoing hot or cold rolling. It possesses a dull gray appearance and is typically employed in applications where aesthetics are not of paramount importance. On the other hand, the galvanized finish is a favored choice, whereby a layer of zinc is coated onto the steel sheet to safeguard it against corrosion. This finish exhibits exceptional resistance to corrosion and is frequently utilized in automotive body panels and structural components. Another option is the painted finish, which involves coating the steel sheet with a layer of paint. This finish improves both the aesthetics and corrosion protection of the steel sheet. Painted finishes are available in a variety of colors and textures, offering customization and branding possibilities. Furthermore, specialized finishes, such as the electro-galvanized finish, are also available. This finish involves the application of a thin layer of zinc to the steel sheet through an electroplating process. It provides enhanced corrosion resistance and is commonly employed in automotive parts that necessitate a high level of rust protection. Lastly, the brushed or polished finish entails mechanical polishing of the steel sheet surface to create a smooth and reflective appearance. This finish is often used for decorative purposes in automotive applications, like trim or accents. In conclusion, the range of steel sheet finishes for automotive applications includes mill finish, galvanized finish, painted finish, electro-galvanized finish, and brushed/polished finish. Each finish offers distinct advantages in terms of appearance, durability, and corrosion resistance, enabling manufacturers to select the most suitable option for their specific automotive application.

- Q: Can steel sheets be used for agricultural buildings or barns?

- Agricultural buildings or barns can indeed make use of steel sheets. The utilization of steel sheets for such structures offers a plethora of benefits. To begin with, steel is a robust and enduring material, guaranteeing the longevity of the agricultural building or barn even in the face of various weather conditions and the test of time. Additionally, steel is resistant to pests, such as termites, which often pose significant problems for wooden structures. Moreover, steel sheets possess fire-resistant qualities, thus providing an extra layer of safety. Furthermore, steel sheets allow for a high degree of customization, enabling flexibility in design and construction. They can be easily cut and shaped to suit the specific needs and requirements of the agricultural building or barn. Steel sheets are available in various thicknesses, offering options for different levels of strength and structural integrity. In addition, opting for steel presents an environmentally friendly choice for agricultural buildings or barns. This is due to steel being a recyclable material, meaning that it can be repurposed and reused at the end of its lifespan. This not only reduces waste but also minimizes the environmental impact. Taking all these factors into consideration, it is evident that steel sheets are an excellent option for agricultural buildings or barns, given their durability, resistance to pests, fire resistance, customizability, and environmental friendliness.

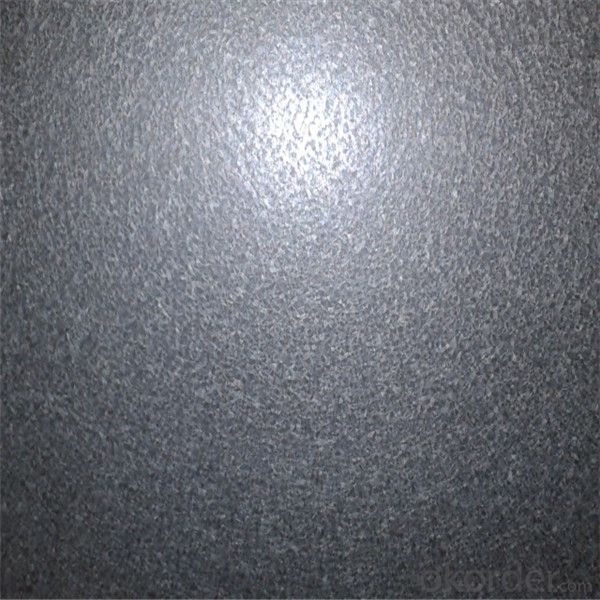

- Q: What are the different surface finishes for galvalume steel sheets?

- Some common surface finishes for galvalume steel sheets include regular spangle, minimized spangle, and zero spangle.

- Q: Can steel sheets be used for elevator manufacturing?

- Yes, steel sheets can be used for elevator manufacturing. Steel is a commonly used material in elevator construction due to its strength, durability, and ability to withstand heavy loads. Steel sheets can be shaped and formed into various components of an elevator, including the cab, doors, and framework, ensuring a sturdy and reliable structure.

- Q: Are steel sheets suitable for industrial machinery components?

- Yes, steel sheets are suitable for industrial machinery components due to their high strength, durability, and ability to withstand heavy loads and extreme conditions commonly found in industrial settings. Steel sheets also offer excellent machinability, allowing for precise shaping and customization of components as per specific requirements. Additionally, steel sheets can be easily welded, offering flexibility in design and assembly processes.

- Q: Can steel sheets be used for electromagnetic shielding?

- Yes, steel sheets can be used for electromagnetic shielding.

- Q: How are steel sheets transported?

- Steel sheets are typically transported using various methods, depending on the quantity, size, and destination. One common method is by truck, where the steel sheets are loaded onto flatbed trailers or enclosed trucks. This allows for easy transportation and flexibility in reaching different locations. For larger quantities or long-distance transportation, steel sheets can be transported by rail. They are usually loaded onto specialized railcars designed to securely hold and transport heavy loads. Rail transportation is efficient for long distances and can handle larger volumes of steel sheets. In some cases, steel sheets may also be transported by sea. They are loaded onto shipping containers or directly onto ships designed for bulk cargo. This method is usually used for international shipments or when transporting large quantities of steel sheets across long distances. Regardless of the transportation method, it is crucial to ensure that the steel sheets are properly secured and protected during transit to prevent damage or loss. This may involve using straps, chains, or other securing devices to hold the sheets in place and protect them from shifting or external factors such as weather conditions. Overall, the transportation of steel sheets requires careful planning and coordination to ensure safe and efficient delivery to their intended destination.

- Q: What is the difference between an open plate and an original plate?

- Open and flat from the original flat surface color to distinguish. Because the Kaiping plate originally is rolled strip, the oxide is less, the same time the Kaiping plate and the original flat for a period of time after the original flat in different colors, red, and blue plates.

Send your message to us

Aluzinc coated galvanized steel sheet AFP SGCL

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords