Pre-painted Aluzinc Steel Coil PPGL in Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

inted Galvanized Steel Coil

1. Defination of Prepainted Galvanized Steel Coil

Pre-painted coils are produced by coating a layer of paint on the surface of cold rolled, galvanized or galvalumed coils. Aesthetic appeal and durability are the key festures of color coated steel coil. A wide selection of colors is available to the customer and paints designed to meet specific end use could be specified.

2. Applications of Prepainted Galvanized SteelCoil

1) Buildings and constructions: roofing, ceilings, gutters, venting lines, indoor decorations, window frames, etc.

2) Electrical appliances: computer shells, washing machines, refrigerators, dehumidifiers, video recorders, water heaters, etc.

3) Agricultural equipments: troughs, feeding tools, agricultural driers, irrigation channels, etc.

4) Vehicle parts: back-seat plates of buses and trucks, conveying systems, oil tanks, etc.

3. Specifications of Prepainted Galvanized SteelCoil

Standard: ASTM;ASTM;JIS;GB

Grade: SGCC;(DX51D)

Thickness: 0.12-1.2mm

Width: 750-1250mm

Length: Coil or customer's requirements

Zinc Coating: 60-140g/m2

Painting : Top side from 15-25um; Bottom side from 5-10 um

Color : RAL numbers or customers' sample color

Application: building trade, electric apparatus, furniture and transport service

Production arts and crafts : Double coated double drying

Coil ID: 508mm

Coil Weight: 3-6 Ton

Type :coil

Packaging Detail: Fully seaworthy export packing with paper tube or as per customer's requirements

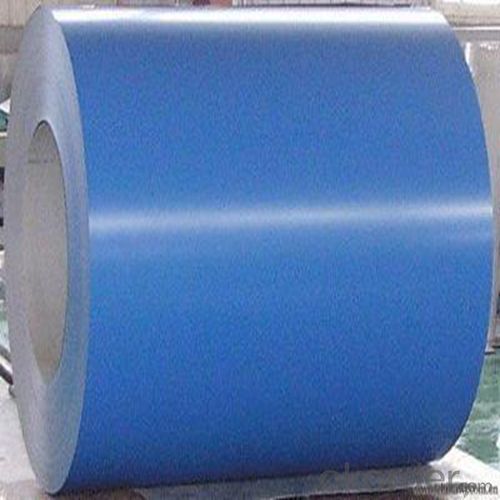

4. Prepainted Galvanized Steel Coil Images

5. Advantages of Our Prepainted Galvanized SteelCoil

1) Excellent corrosion resistance: The zinc layer provides a good protection of Pre-painted Galvanizeed Steel Sheet.

2) High heat resistance: The reflective surface of the material aids in efficiently reflecting the sunlight away and in turn reducing the amount of heat transmitted. The thermal reflectivity converts into energy savings.

3) Aesthetics: Pre-Painted Galvanized steel sheet is available in plethora of patterns and multiple sizes as per the requirements that given by our customers.

4) Versatility: can be used in the various areas.

6. FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What is the average fire rating for steel sheets?

- The fire rating of steel sheets can differ based on different factors, including sheet thickness, steel type, and fire testing standards. Generally, steel sheets have fire ratings between 30 minutes and 2 hours. However, it's worth noting that fire ratings can be improved by adding fire-resistant materials or applying fire-resistant coatings to the sheets. To determine the precise fire rating for a specific steel sheet, it is advisable to seek guidance from fire safety professionals or consult the relevant fire testing standards.

- Q: What is the difference between plain carbon steel sheet and stainless steel sheet?

- The main difference between plain carbon steel sheet and stainless steel sheet lies in their composition and properties. Plain carbon steel sheet is primarily made of iron and carbon, with trace amounts of other elements. It is susceptible to rust and corrosion, requiring regular maintenance and protection. On the other hand, stainless steel sheet is an alloy of iron, carbon, and chromium, with additional elements like nickel and molybdenum. It has a higher resistance to rust and corrosion, making it suitable for applications in harsh environments. Stainless steel sheet also offers better strength and durability compared to plain carbon steel sheet.

- Q: Are steel sheets suitable for laser cutting or engraving?

- Yes, steel sheets are suitable for laser cutting or engraving.

- Q: What is the difference between a hot rolled and cold rolled galvanized steel sheet?

- The manufacturing process and resulting properties of a galvanized steel sheet differ between hot rolled and cold rolled. Hot rolled sheets are created by heating a large steel slab or billet above its recrystallization temperature, usually around 1700°F (926°C). This high temperature allows for easy shaping and forming of the steel into the desired thickness and dimensions. It also refines the grain structure and produces improved mechanical properties and a more uniform distribution of alloying elements. On the other hand, cold rolled sheets are manufactured at room temperature by passing the hot rolled sheet through rollers that compress and shape the material. This reduces the thickness of the sheet, increases its tensile strength, and improves its surface finish. Cold rolling also allows for tighter tolerances and more precise dimensions, making it suitable for applications that require high precision and consistency. In terms of properties, hot rolled sheets have a rougher surface finish due to the high temperature processing. However, they are generally more ductile and easier to form or bend compared to cold rolled sheets. Hot rolled sheets also have a slightly thicker oxide layer on the surface, providing additional corrosion resistance. On the other hand, cold rolled sheets have a smoother and more polished surface finish. They are typically thinner and have a higher strength-to-weight ratio compared to hot rolled sheets. The cold rolling process also results in a more homogeneous microstructure, improving the overall mechanical properties such as hardness and toughness. Ultimately, the choice between hot rolled and cold rolled galvanized steel sheets depends on the specific requirements of the application. Hot rolled sheets are often preferred for applications that require easy formability and a rougher surface finish, while cold rolled sheets are favored for their higher strength, tighter tolerances, and smoother surface finish.

- Q: What does "steel plate 10t" mean in the specification column of engineering material?

- 10T refers to the steel plate thickness of 10mm.Steel plate is made of molten steel, cooled and compressed into flat steel.The steel plate is flat, rectangular, and can be rolled directly or cut from a wide strip of steel.

- Q: How thick are steel sheets typically?

- Steel sheets can vary in thickness depending on their intended use, but they are typically available in thicknesses ranging from 0.5mm to 6mm for general applications.

- Q: What is the difference between a painted and powder coated steel sheet?

- The application process and resulting finish distinguish painted steel sheets from powder coated steel sheets. Painted steel sheets are typically covered with a liquid paint, which can be applied through various methods such as spraying, brushing, or dipping. This liquid paint contains pigments and binders that stick to the steel surface and create a protective layer. It is possible to customize the paint in terms of color, gloss, and texture, allowing for a multitude of design options. However, painted surfaces may be susceptible to chipping, peeling, and fading over time, especially in harsh environments or with exposure to UV radiation. On the other hand, powder coated steel sheets are coated with a dry powder, which is electrostatically administered to the steel surface. The powder consists of a blend of finely ground particles, including pigments, resins, and additives. When applied, the steel sheet is heated, causing the powder particles to melt and fuse together, resulting in a sturdy and consistent coating. The outcome is a smooth, uniform finish that offers exceptional resistance to chipping, scratching, and UV radiation. Powder coating also provides a wider range of color choices and finishes compared to traditional liquid paint. In conclusion, although both painted and powder coated steel sheets offer protection and aesthetic appeal, powder coating provides superior durability, damage resistance, and a broader range of design possibilities.

- Q: What is the price range of steel sheets?

- The price range of steel sheets can vary greatly depending on factors such as the type of steel, thickness, size, and market demand. It is advisable to check with suppliers or conduct research to get specific and up-to-date pricing information.

- Q: Can steel sheets be used for bridge construction?

- Yes, steel sheets can be used for bridge construction. Steel is a commonly used material in bridge construction due to its high strength, durability, and ability to withstand heavy loads. Steel sheets are often used to create beams, girders, and other structural components in bridges, providing the necessary support and stability.

- Q: What kind of steel plate is HIC?

- Hydrogen sulfide corrosion resistant steel plate is generally used in some specific occasions, LONCIN steel grid plate for you to answer

Send your message to us

Pre-painted Aluzinc Steel Coil PPGL in Great Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords