Pre-Painted Aluzinc Steel Coils/ Sheets /PPGI with Super Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specifications

Prepaint Aluzinc Steel Coil

.Thicknee:0.10-1.20mm

.Width:600-1250mm

.Good quality and service

.Standard Export seaworthy

2. PREPAINTED GALVANIZED STEEL

. Prepainted Steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

. The base metals for Prepainted Steel Coil consist of cold rolled, galvanized The finish coats of Prepainted Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3.High Quality Pre-Painted Aluzinc Steel Coil

Product Description

| Commodity | Prepainted Galvalume Steel Coil/Sheet | ||||||||

| Standard | Q/BQB445 JISG3322 EN10327 | ||||||||

| Grade | TDC51D+AZ/TDC52D+AZ/TS250GD+AZ/TS300GS+AZ/TS350+AZ/TS350GD+AZ/TS550GD+AZ/CGLCC/ | ||||||||

| CGLCD/CGLC490/CGLC570/DX51D+AZ/DX52D+AZ/S250GB+AZ/S300GD+AZ/S350GD+AZ/S550+AZ | |||||||||

| Thicknees | 0.16-1.2 mm | Width | 600-1250mm | ||||||

| Zinc Coating | AZ30-AZ150g/m2 | Coil Weight(Min or Max) | 3-8 tons | ||||||

| Coil Inner Diameter | 508mm | 610mm | Coil Outer Diameter(Max) | ||||||

| Color | Ral Color | As Customers' requirement | |||||||

| Surface Finish | Normal Coated | Embossed | Printed | ||||||

| Category Of Finish Coating | High-durability Polyester | Silicon Modified Polyesters | |||||||

| Polyvinylidene Fluoride | Polyester | ||||||||

| Anti-static | Easy-Cleaning | ||||||||

| Coating Type | Top Surface | Bottom Surface | |||||||

| Double Coated | Double Coated | ||||||||

| Double Coated | Single Coated | ||||||||

| Coating Thickness | Top Surface: | Back Surface: | |||||||

| Coating Structure | Primer | Finish Coating | |||||||

| Epoxy Primer | Polyester | ||||||||

| Polyester Primer | Silicon Modified Polyesters | ||||||||

| Water-soluble Acrylic Acid Primer | High-durability Polyester | ||||||||

| Polyurethane Primer | Polyvinylidene Fluoride | ||||||||

| Method of Test | <1>Acid/Alkaline-Resistance Test | <2>Test of Resistance to Neutral Mist | |||||||

| <3>Air Exposure Test | |||||||||

| Futher Process | Cut coil into Sheet | Corrugated Roofing Sheet | |||||||

Application | Construction | Outside | workshop,agricultural,warehouse,corrugated roof,wall,etc | ||||||

| Inside | doo,doorcase,light steel roof structure,vent gutter,etc | ||||||||

| Electial Appliance | refrigetator.washer,switch cabinet,etc | ||||||||

| Furniture | central heating slice,lampshade,etc | ||||||||

| Carrying Trade | clapboard,container,etc | ||||||||

| Others | writing panel,garbage can,timekeeper,etc | ||||||||

Applications

construction | workshop, agricultural warehouse, residential precast unit, corrugated roof, wall, rainwater drainage pipe, terrace, retailer booth, roller shutter door |

door, doorcase, light steel roof structure, folding screen, ceiling, elevator, stairway, vent gutter | |

Electrical appliance | refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker |

Furniture | central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf |

Carrying trade | exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board |

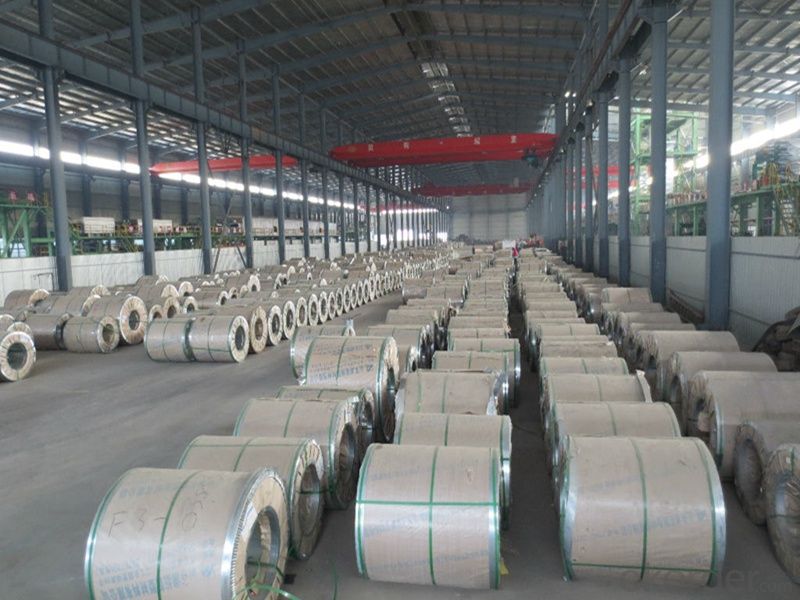

4. Pictures

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of color steel coils,is one of the large-scale professional investment steel production bases in China. Annually more than 8000 tons Precision Steel coils to be exported for more than 60 countries.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 10 to 15 working days can be served.

- Q: I am a beginner (never played before!) and I am going to try to teach myself since I think it is a lovely instrument. I am fourteen-years-old so I am not 'adult-size', haha. Anyway, what is difference between nylon strings and steel strings?Thanks :)

- Make your choice based on the type of music you intend to play. Nylon strings are used primarily for classical, flamenco and folk music. Steel strings are used for pop, rock, blues, country, folk, bluegrass.... Both types of guitar are tuned the same, so you *can* play any style of music on either guitar. The big difference is in the tone. Nylon strings are rich and full...if perhaps a little mellow. Steel strings are twangy and have a bite to the sound. There are differences in the construction and feel of the guitars, but that's not critical to your decision. Match the guitar to the music you intend to play. At 14 yrs old, you are certainly big enough for a full sized guitar....and I'll bet you're still growing, right? Even full sized guitars still vary in the size of the body. Try a few out to see how well they fit your reach.

- Q: Is Ace Steel's wrestling school still running?And do you know if their are any other wrestling schools in chicago?

- the Steel Domain wrestling school thats where cm punk got trained at i live in cleveland but i was in chicago last month and took a tour of the school.

- Q: What is the role of steel coils in the manufacturing of agricultural machinery?

- Steel coils are essential in the manufacturing of agricultural machinery as they are used to form various components such as frames, chassis, and structural supports. These coils provide the necessary strength, durability, and rigidity required to withstand the demanding conditions and heavy workload typically encountered in the agricultural sector.

- Q: What are the different methods of uncoiling steel coils?

- There are several methods used for uncoiling steel coils, including hydraulic uncoiling, motorized uncoiling, and manual uncoiling. Hydraulic uncoiling involves using hydraulic cylinders to unwind and release the tension in the coil. Motorized uncoiling utilizes a motorized mandrel or decoiler to unwind the coil. Manual uncoiling, on the other hand, requires physical effort to unwind the coil by hand. Each method has its own advantages and is chosen based on the specific requirements and capabilities of the uncoiling process.

- Q: How do the sandpaper grits compare with different coarse levels of steel wool? For example, I'm finishing a homemade entertainment center, and using a tinted polyurethane, and it says to use 000 grade steel wool, but mine is #3, could I use some sanpaper instead, and what grit?

- 150 grit is standard for final sanding for poly. You could use 220 if you finish with something thinner like lacquer of if that's all you have. Even finer would work but not do much sanding.

- Q: I want to start getting throwing knives and i was wondering what material is best for quality, but still cheap. I also saw some 440 stainless steel knives that i liked and wanted to know if the material was good

- Good steel ain't cheap, cheap steel ain't good... If you're just starting out (practicing anyways), I would be less concerned about the material and more concerned about the style and shape of the blade to gain consistency in your technique... When you start getting proficient for competitions and such... then I'd start investigating steel grades... Anyways, here's a summary from the wiki: Type 440—a higher grade of cutlery steel, with more carbon, allowing for much better edge retention when properly heat-treated. It can be hardened to approximately Rockwell 58 hardness, making it one of the hardest stainless steels. Due to its toughness and relatively low cost, most display-only and replica swords or knives are made of 440 stainless. Available in four grades: 440A, 440B, 440C, and the uncommon 440F (free machinable). 440A, having the least amount of carbon in it, is the most stain-resistant; 440C, having the most, is the strongest and is usually considered more desirable in knifemaking than 440A, except for diving or other salt-water applications.

- Q: How are steel coils inspected for yield strength using tensile testing?

- Tensile testing is the method used to inspect the yield strength of steel coils. This involves subjecting a sample of the coil to controlled tension until it reaches its breaking point. Through this test, various mechanical properties of the steel, including yield strength, can be determined. To conduct the tensile testing for yield strength inspection, a small strip of the coil is cut and prepared. The strip is then placed in a machine specifically designed for tensile testing. This machine consists of two grips that securely hold the strip at opposite ends. Subsequently, the machine applies a steadily increasing force to the strip, causing it to elongate until it eventually breaks. Throughout the test, the machine measures the force applied and the elongation of the strip. The yield strength is determined by identifying the point on the stress-strain curve where the material begins to undergo plastic deformation, meaning it exhibits permanent deformation without any increase in load. Typically, the yield strength is reported as the stress required to cause a specific amount of plastic deformation, such as 0.2% or 0.5%. This value represents the maximum stress that the steel can endure without experiencing permanent deformation. By performing tensile testing on a sample of the steel coil, it becomes possible to ascertain its yield strength. This information is vital in ensuring the quality and dependability of the steel coil, as it indicates the maximum stress it can tolerate before permanent deformation occurs. Furthermore, this testing method allows for the comprehensive evaluation of other mechanical properties, including ultimate tensile strength, elongation, and modulus of elasticity, thus providing a thorough understanding of the steel's performance characteristics.

- Q: The difference between aluminized color steel roll and ordinary color steel roll

- Ordinary color steel roll is a composite material, also known as color coated steel plate, is used in the continuous production line on the production line after surface degreasing, phosphating and other chemical coating treatment, painted with organic coatings, made by baking products. Both steel and organic materials are a little bit different. Both the mechanical strength of steel plate and easy molding performance, but also organic materials, good decoration, corrosion resistance.

- Q: Is there much difference? Which is better? Are they equally safe? Is it just personal preference? Can you reccomend a good comfortable steel composite toe boot?

- steel toe boots are just that a piece of steel fitted over the toes, composite toe boots use other materials that are just as hard BUT they do not have the connectivity levels as steel. if you are working in a cold climate steel toes will freeze them toes right off, also electrical environments. my advice get a good pair of composite ones, and you get what you pay for, its worth the investment. more than you could ever imagine. proper foot support. helps legs cramps, back pain etc...

- Q: Does steel have a valence number and if so, what is it?

- Steel is a mixture, so it doesn't have any valence number. On the other hand, all of the components of the steel mixture are in their elemental forms, so all the various valences are zero.

Send your message to us

Pre-Painted Aluzinc Steel Coils/ Sheets /PPGI with Super Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords