Aluzinc Steel Sheet in Coil with Prime Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluzinc Steel Coil Description:

Hot-dip aluzinc steel sheet is substrated on cold rolled steel(CRC) in various strength and specification. Coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance. It is especially useful for countless outdoor and industrial applications.

2.Main Features of the Galvanized Steel Coil:

• Base material for countless outdoor and industrial applications

• Excellent corrosion resistance

• Excellent heat resistance performance

• High strength

• Good formability

• Rust- proof ability

• Good visual effect

3. Aluzinc Steel Coil Images

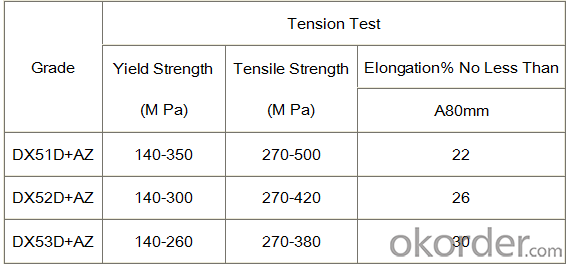

4.Aluzinc Steel Coil Specification

Thickness: 0.3-0.7mm

Width: 914-1250mm

Inner Diameter: 508-610mm

Weight of Steel Coil: 3-15MT

Coating Type: Al-Zn Alloy

Available Dipped Layer: 50-150g/m2

Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

Available Surface Treatment: Passivating & Oiling & AFP & Filming

5.FAQ of Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Hello,I have been thinking about buying a Tungsten Carbide Diamond wedding band for my husband but one of my family members keep telling me that Tungsten Carbide is merely steel and hence, a low quality metal, therefore, I shouldn't buy it. I don't really know much about it. Please if anyone can tell me more about this metal? Thanks.

- Tungsten is not steel. Tungsten is a chemical element. What they do is add an alloy mixture to tungsten and it turns into Tungsten Carbide. You want to find a ring with a nickel alloy, some manufacturers cheap out and add cobalt instead. Make sure the ring you buy does not contain cobalt. Steel is an alloy consisting mostly of iron, with a carbon.

- Q: For the purpose of blade crafting. I need to heat treat this low quality steel i got.It's ASTM A36Is heat treatable and temperable?

- A36 is plain carbon structural steel. A36 could almost be considered junk steel. It is not suitable for cutting tools in any respect, as it is far to soft to hold an edge. A36 generally cannot be heat-treated, A36 can only be strengthened by cold-working, and even then, only up to about 60,000 psi. Heating the steel will only make it softer. The only real virtue of A36 is that it's easy to work with, it's easily cut and machined and it is very easy to weld. This is good for making steel structure, but not for knives. Probably the most popular material for knife blades is type 440C stainless. 440C is easy to work with in the un-treated state, and the heat treatment procedure is relatively simple.

- Q: How are steel coils used in the manufacturing of aerospace components?

- Steel coils are used in the manufacturing of aerospace components as they provide a reliable and durable material for various applications. The coils are typically cut and formed into different shapes to create components like structural supports, brackets, and fasteners. These components play crucial roles in the construction and assembly of aerospace systems, ensuring strength, stability, and safety in the final products.

- Q: What are the different types of steel alloys used in coils?

- There are various types of steel alloys used in coils, including carbon steel, stainless steel, galvanized steel, and electrical steel.

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications across various industries, including automotive, construction, manufacturing, and appliance sectors. They are commonly used in the production of automobiles, machinery, and infrastructure components like bridges and buildings. Additionally, steel coils are utilized in the manufacturing of household appliances, such as refrigerators and washing machines. Their versatility, strength, and durability make steel coils a crucial material for many industrial applications.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or sunken designs on a material, and it can be applied to steel coils to add texture or decorative patterns.

- Q: Does SA use its own iron ore to produce steel for construction or do we rely on imports?

- SA got its own steel and iron production going that is one of our main exports They don't make Rail's for railway line any more we in port it

- Q: Can steel coils be coated with anti-tampering materials?

- Yes, steel coils can be coated with anti-tampering materials. These coatings are designed to enhance security measures and deter any unauthorized access, tampering, or theft of the steel coils.

- Q: How do steel coils contribute to energy efficiency in buildings?

- Steel coils contribute to energy efficiency in buildings by enhancing insulation and reducing heat transfer. These coils are often used in heating, ventilation, and air conditioning (HVAC) systems to efficiently regulate temperature. The coils help transfer heat effectively, allowing for better control over indoor climate and reducing the energy required for heating or cooling. Additionally, steel coils are durable and require less maintenance, making them a cost-effective solution for long-term energy efficiency in buildings.

- Q: What are the cost considerations when purchasing steel coils?

- When purchasing steel coils, there are several cost considerations that need to be taken into account. Firstly, the price per unit of steel coil is a significant factor. The cost of steel coils can vary depending on various factors such as the type of steel, its grade, thickness, width, and length. Higher-grade steel coils tend to be more expensive than lower-grade ones, and thicker or wider coils can also come at a higher cost. Another cost consideration is the quantity of steel coils needed. Purchasing larger quantities of steel coils often comes with volume discounts, so it is important to determine the required quantity and assess whether it is more cost-effective to buy in bulk or in smaller batches based on the demand and storage capacity. Transportation costs should also be considered when purchasing steel coils. The weight and size of the coils can impact the shipping costs, especially if they need to be transported over long distances. Additionally, the distance between the supplier and the buyer can affect freight charges, so it is crucial to evaluate different shipping options and choose the most cost-effective method. Furthermore, it is essential to take into account any additional costs associated with processing or customizing the steel coils. For instance, if the coils need to be cut, leveled, or coated, these additional services can add to the overall cost. It is important to obtain quotes from different suppliers and compare the prices for these value-added services. Lastly, it is crucial to consider the overall quality and reliability of the steel coils. While cheaper options may initially seem more cost-effective, they could end up costing more in the long run if they do not meet the required standards or have a shorter lifespan. It is advisable to choose reputable suppliers with a track record of delivering high-quality products to ensure that the investment in steel coils is worthwhile. In conclusion, the cost considerations when purchasing steel coils include the price per unit, quantity discounts, transportation costs, additional processing services, and the overall quality and reliability of the coils. Evaluating these factors thoroughly will help make an informed decision that balances cost-effectiveness with the desired quality and specifications of the steel coils.

Send your message to us

Aluzinc Steel Sheet in Coil with Prime Quality and Best Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords