Prime Quality Aluzinc Coated Galvanized Steel Sheets & Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

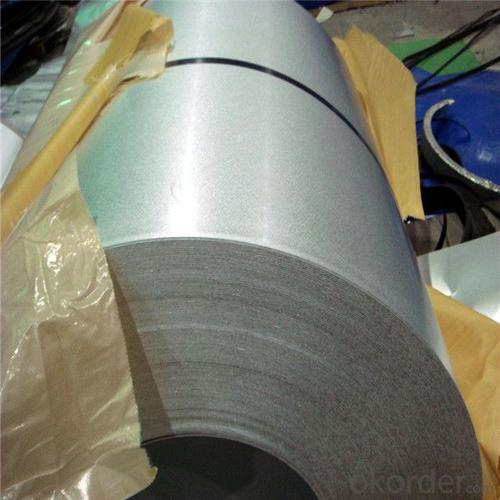

Hot –dip aluzinc steel sheet/coil is substrated on cold rolled steel (CRC) in various strength and

specification. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon,

with excellent corrosion and heat resistance performance.

Strong, yet lightweight, Galvalume wont crack or peel when subjected to weather. Galvalume consists

of 55% aluminum, 43.4% zinc and 1.6% silicon over the base metal. This coating is applied during

a continuous hot-dip process. AZ40, AZ50, AZ55 and AZ60 translate to the coating thickness of .40,

.50, .55 and .60 ounces per square foot, respectively.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich

walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

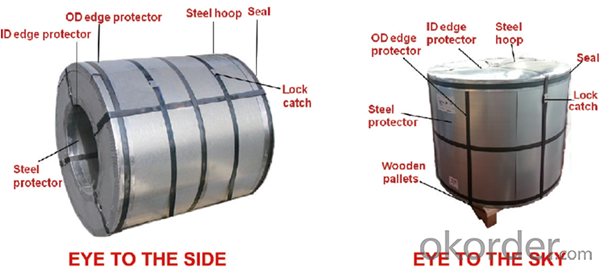

Packaging & Shipping

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

Our Services

MOQ | FCL, 25 metric tons per 20GP, can be assorted with different sizes. |

LCL for trial order is acceptable. | |

Price Term | EX-WORK, FOB China Port, CNF, CIF |

Payment | T/T, 30% advanced payment before production and balance before shipment; OR Irrevocable L/C at sight. |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the

specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers.

For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for

Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: What is the weight of a steel coil?

- The weight of a steel coil can vary depending on its size and thickness. Generally, a steel coil can weigh anywhere from a few hundred kilograms to several tonnes.

- Q: How are steel coils used in the production of agricultural structures?

- Due to their exceptional strength and durability, steel coils find extensive use in the production of agricultural structures. These coils, typically composed of high-quality steel, have various applications within the agricultural industry. One major application of steel coils in agricultural structures involves the construction of buildings and storage facilities. By using steel coils, farmers can create robust frameworks that support the walls and roofs of these structures. The inherent strength of steel allows for the construction of spacious areas without the need for excessive support columns, providing farmers with ample storage space for their crops, machinery, and livestock. Furthermore, steel coils play a crucial role in the manufacturing of agricultural equipment and machinery. Whether it be tractors, plows, harvesters, or irrigation systems, steel coils are essential in the fabrication of these tools. The high tensile strength of steel ensures that these agricultural machines can endure the rigorous conditions of farming, including heavy loads, rough terrains, and exposure to harsh weather elements. Moreover, steel coils are also indispensable in the production of fencing and enclosures for agricultural purposes. Whether it's safeguarding crops from animals or establishing boundaries for livestock, steel coils are a vital component in constructing robust and reliable fences. The strength of steel guarantees that these fences can withstand the pressure from animals, preventing them from breaking through and causing harm to the crops or escaping. In conclusion, steel coils are a vital component in the production of agricultural structures and equipment. Their strength, durability, and versatility make them an ideal material for constructing buildings, manufacturing machinery, and creating fences in the agricultural industry.

- Q: How do steel coils contribute to the marine vessel construction industry?

- Steel coils are essential components in the marine vessel construction industry as they play a crucial role in the fabrication of various structural elements of ships and boats. These coils are typically made of high-quality steel and are used in a variety of ways to contribute to the construction and performance of marine vessels. Firstly, steel coils are utilized in the construction of the hull, which is the main body of the ship. The hull requires strong and durable materials to withstand the harsh conditions of the sea, including waves, corrosion, and impacts. Steel coils provide the necessary strength and integrity to the hull, ensuring the vessel's structural integrity and safety. Moreover, steel coils are also employed in the fabrication of decks, bulkheads, and other internal structures of marine vessels. These components are crucial for dividing the ship into compartments, providing stability, and supporting various equipment and machinery. Steel coils are known for their excellent tensile strength, which allows them to bear heavy loads and resist deformation, making them ideal for constructing these vital components. Additionally, steel coils are used in the construction of propulsion systems and other mechanical parts of marine vessels. These coils are often shaped and formed into specific components, such as shafts, gears, and propellers, which are critical for the vessel's propulsion and maneuverability. The high strength and durability of steel coils ensure the reliability and efficiency of these mechanical systems, enabling smooth navigation and operation of the vessel. Furthermore, steel coils contribute to the marine vessel construction industry by enhancing the overall safety and longevity of ships and boats. Steel is known for its resistance to corrosion, which is a significant concern in marine environments due to the presence of saltwater. By utilizing steel coils, marine vessels can withstand the corrosive effects of seawater, reducing the need for frequent maintenance and repair. This, in turn, improves the lifespan of the vessel and reduces the risk of accidents or failures at sea. In conclusion, steel coils are indispensable in the marine vessel construction industry. These coils provide the necessary strength, durability, and resistance to corrosion, ensuring the safety, performance, and longevity of ships and boats. From the construction of the hull to the fabrication of internal structures and mechanical components, steel coils play a vital role in every aspect of marine vessel construction.

- Q: What are the advantages of using steel coils in construction?

- There are several advantages of using steel coils in construction. Firstly, steel coils are extremely strong and durable. They have a high tensile strength, which means they can withstand heavy loads and resist deformation. This makes them ideal for structural applications in construction, such as beams, columns, and frames. Secondly, steel coils are highly versatile. They can be easily shaped and molded into various forms, allowing for flexibility in design and construction. Steel coils can be rolled, bent, cut, and welded to meet specific project requirements. This adaptability makes them suitable for a wide range of construction applications. Another advantage of using steel coils in construction is their resistance to corrosion. Steel coils are often coated with protective coatings, such as galvanized or stainless steel, to prevent rusting and corrosion. This ensures that the structural integrity of the building remains intact over time, even in harsh environmental conditions. Furthermore, steel coils offer excellent fire resistance. Unlike other construction materials like wood, steel does not burn or contribute to the spread of fire. This makes it a safer choice for construction, particularly in high-rise buildings or areas prone to fire hazards. Lastly, steel coils are cost-effective. While the initial cost of using steel coils may be higher compared to some other materials, their longevity and low maintenance requirements make them a cost-efficient option in the long run. Steel coils have a long lifespan and require minimal repairs or replacements, resulting in reduced maintenance costs and increased overall value. In conclusion, the advantages of using steel coils in construction include their strength, versatility, corrosion resistance, fire resistance, and cost-effectiveness. These qualities make steel coils an excellent choice for various construction applications, contributing to the durability and safety of buildings.

- Q: What are the different types of steel coil edge conditioning methods?

- There are several different types of steel coil edge conditioning methods, including slitting, trimming, deburring, chamfering, and edge rolling.

- Q: Myself, iam Working In a Steel Fabrication Company. I completed my Engineering in 2006 and immediately recruited in this company in Oman. My company is Steel Fabrication company .So as i am new to this field, i just need some basic knowledge regarding this Steel Fabrication.Waiting for ur early reply.

- There is SO much information regarding steel fabrication. A simple Google search could prove to be very helpful, but more than likely, you are going to need information from an actual company. Check these guys out. They seem to have quite a bit of information into their process. They also have a lot of process sheets.

- Q: What are the different methods of steel coil surface cleaning?

- There are several methods of steel coil surface cleaning, including mechanical cleaning, chemical cleaning, and high-pressure water cleaning. Mechanical cleaning involves using abrasive materials or brushes to physically remove dirt, rust, and other contaminants from the surface. Chemical cleaning uses various chemicals or solvents to dissolve or loosen the contaminants, making them easier to remove. High-pressure water cleaning involves spraying water at a high pressure to dislodge and wash away the dirt and debris. These methods can be used individually or in combination, depending on the level of cleanliness required and the specific condition of the steel coil.

- Q: What are the common applications of galvanized steel coils?

- Galvanized steel coils are commonly used in a variety of applications such as construction, automotive manufacturing, and the production of household appliances. They are used for roofing, siding, and structural components in buildings due to their corrosion resistance and durability. In the automotive industry, galvanized steel coils are used for manufacturing car parts, such as body panels and frames, to enhance their strength and longevity. Additionally, they are utilized in the production of household appliances like refrigerators, washing machines, and air conditioning units, as the galvanized coating protects against rust and extends the lifespan of these products.

- Q: What are the common methods of inspecting steel coils for quality control?

- The common methods of inspecting steel coils for quality control include visual inspection, dimensional measurement, surface inspection, and mechanical testing. Visual inspection involves checking for any visible defects or abnormalities such as cracks, dents, or scratches. Dimensional measurement ensures that the coils meet the specified size and thickness requirements. Surface inspection involves examining the surface finish, cleanliness, and coating integrity. Mechanical testing involves conducting various tests to assess the strength, hardness, and other mechanical properties of the steel coils. These methods collectively ensure that the steel coils meet the required quality standards.

- Q: 1943 steel pennies

- if you collect coins, you need to learn that they must never be cleaned. cleaning, while it might make them look pretty, ruins their value as a collectable. ask your coin dealer.

Send your message to us

Prime Quality Aluzinc Coated Galvanized Steel Sheets & Coils

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 14567 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords