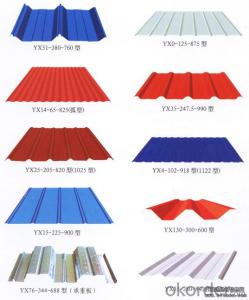

Corrugated Steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1) AVAILABLE DESIGNATION OF (Prepainted galvanized steel coils) printed PPGI coils

Quality Q/BQB 440-2003 JIS G3312-1994 EN 10326-2004 ASTM A653-02a

EN 10327-2004 (BASE PLATE)

(BASE PLATE)

Commercial Steel TDC51D CGCC DX51D+Z/AZ CS Type A/B/C

Forming Steel (TSt01,TSt02,TSt03) CGCD1 FS Type A, Type B

Drawing TDC52D /TDC53D - DX52D+Z/AZ DDS TYPE A/C

Steel DX53D+Z/AZ

Structural TS280GD(TStE28) CGC400 S280D+Z/AZ SS275

Steel TS350GD(TStE34) CGC440 S350D+Z/AZ SS340 Class1

2) OUR SPECIFICATION OF (Prepainted galvanized steel coils) printed PPGI coils

Available Size:

Manufacturer Thickness Width Length of plate Inner diameter of coil

JIANGSU HUIYE STEEL SHEET CO.,LTD 0.2-1.2mm 800/914/1000/1200/1219/1250mm 1000-6000mm 508mm/610mm

Coated Mass OF (Prepainted galvanized steel coils) printed PPGI coils:

Base plate Available Coated Mass(g/m^2)

Galvanized Steel 80, 100, 120, 160, 180

Galvalume Steel 50, 70, 150

Available Painting OF (Prepainted galvanized steel coils) printed PPGI coils:

Category of Painting Item Code

Polyester PE

High-durability polyester HDP

Silicon modified polyesters SMP

Polyvinylidene fluoride PVDF

Easy-Cleaning —

Painting Thickness Top side: 20+5microns;

Bottom side: 5~7microns.

Color System Produce according to RAL Color System or as per buyer’s color sample.

Painting structure Top surface Bottom surface

Primer coating No coating 1/0

Primer coating Primer coating 1/1

Primer coating + Finish coating No coating 2/0

Primer coating + Finish coating Primer coating or single back coating 2/1

Primer coating + Finish coating Primer coating + Finish back coating 2/2

- Q: What are the different types of steel sheet finishes for marine applications?

- Marine applications commonly employ several different types of steel sheet finishes to enhance durability and corrosion resistance in the face of constant exposure to moisture, saltwater, and harsh weather conditions. 1. Hot-dip galvanized: Among the most frequently used finishes for marine applications is hot-dip galvanization. This process involves coating the steel sheet with a layer of zinc, effectively safeguarding against corrosion. The zinc layer acts as a sacrificial barrier, preventing rust formation in the underlying steel. 2. Stainless steel: Highly resistant to corrosion, stainless steel sheets find widespread use in marine applications. These sheets are composed of a steel, chromium, and nickel alloy, providing exceptional strength and corrosion resistance. Different grades of stainless steel sheets are available, with 316 stainless steel being the most commonly utilized in marine environments. 3. Powder coating: Powder coating is a favored finish for steel sheets in marine applications. The process involves electrostatically applying a layer of powdered polymer to the steel sheet, which is then cured under heat to form a robust and durable coating. Powder coating offers good corrosion resistance and can be tailored in terms of color and texture. 4. Epoxy coating: To ensure superior protection against corrosion in marine environments, steel sheets are frequently treated with epoxy coatings. These coatings boast chemical resistance and excellent adhesion to the steel surface. Epoxy coatings are also renowned for their high impact and abrasion resistance. 5. Organic coating: Organic coatings, such as polyurethane or acrylic coatings, are employed to shield steel sheets in marine applications. These coatings create a protective barrier against corrosion and are commonly utilized in offshore structures, ships, and other marine equipment. It is important to consider various factors, including specific environmental conditions, budget, and desired aesthetics, when selecting a steel sheet finish for marine applications. Consulting with a professional or referring to industry standards and recommendations can aid in determining the most suitable finish for a particular marine application.

- Q: What are the different types of surface treatments available for steel sheets?

- There are several types of surface treatments available for steel sheets, including galvanizing, painting, powder coating, and plating. Each treatment offers specific benefits in terms of corrosion resistance, aesthetics, and durability, allowing steel sheets to be customized for various applications and environments.

- Q: Are steel sheets suitable for fire-resistant applications?

- Yes, steel sheets are suitable for fire-resistant applications. Steel has excellent fire-resistant properties due to its high melting point, structural integrity, and ability to conduct heat away from the fire. Steel sheets are often used in construction, industrial settings, and transportation where fire safety is a concern.

- Q: Can steel sheets be used for water tanks or storage containers?

- Yes, steel sheets can be used for water tanks or storage containers. Steel is a durable and strong material that can withstand the pressure and weight of holding water or storing various materials. It is commonly used in the construction of water tanks and storage containers due to its resistance to corrosion, ability to maintain structural integrity, and ease of maintenance. Steel sheets can be fabricated into different shapes and sizes to meet specific requirements, making them versatile for various applications. Additionally, steel is a recyclable material, which adds to its sustainability and environmental benefits.

- Q: What are the different surface finishes for steel sheets?

- Some of the different surface finishes for steel sheets include mill finish, brushed finish, mirror finish, embossed finish, and galvanized finish.

- Q: What are the different types of steel sheet finishes for industrial applications?

- Various types of steel sheet finishes are commonly utilized in industrial applications for different purposes. These finishes are applied to steel sheets to improve their appearance, safeguard against corrosion, enhance paint adhesion, and offer other functional advantages. Among the most frequently employed steel sheet finishes are: 1. Hot Rolled: Achieved by subjecting the steel to high temperatures in a furnace, followed by rapid cooling. This process creates a rough, scaled surface suitable for applications where appearance is not the primary concern. 2. Cold Rolled: Processed at room temperature, resulting in a smooth and clean surface. Cold-rolled steel sheets are often used when a high-quality surface finish is required. 3. Galvanized: Involves applying a layer of zinc to the steel sheet to protect against corrosion. Widely used in construction, automotive, and manufacturing industries where durability and resistance to rust are crucial. 4. Electro-galvanized: Similar to galvanizing, this process coats the steel with zinc. However, it utilizes an electric current to deposit a thinner and more controlled zinc coating onto the steel surface. 5. Stainless Steel: Known for its high corrosion resistance, stainless steel sheets are ideal for use in harsh environments. They can be finished with various surface textures, including brushed, mirror, and patterned finishes. 6. Pickled and Oiled: This finish removes any oxide scale from the steel surface using an acid solution and applies an oil coating to prevent rust formation. Commonly used in automotive and construction industries. 7. Painted: Steel sheets can be finished with a layer of paint, which enhances their appearance and provides additional protection against corrosion. The choice of paint depends on the application and desired finish. It is important to note that the examples mentioned above are just a few of the steel sheet finishes used in industrial applications. Different finishes are selected based on specific requirements, such as aesthetics, corrosion resistance, durability, and cost-effectiveness.

- Q: Can steel sheets be used in the manufacturing of appliances?

- Appliances can indeed incorporate steel sheets into their manufacturing process. The manufacturing industry heavily relies on steel due to its exceptional qualities of strength, durability, and versatility. Steel sheets can be manipulated to fit various sizes and designs, catering to the unique specifications of different appliances. Furthermore, steel exhibits resistance against corrosion, rendering it suitable for appliances that may encounter water or other liquids. Additionally, steel serves as an exceptional conductor of heat, proving advantageous for appliances that necessitate efficient heat transfer. Consequently, steel sheets are widely employed in the fabrication of appliances, including refrigerators, ovens, dishwashers, washing machines, and numerous others.

- Q: Can steel sheets be used for staircases?

- Yes, steel sheets can be used for staircases. Steel sheets are often used in the construction of staircases due to their durability, strength, and resistance to wear and tear. They can be molded and shaped into various designs to create aesthetically pleasing staircases while providing a sturdy and long-lasting structure.

- Q: Can steel sheets be used in aerospace applications?

- Yes, steel sheets can be used in aerospace applications. While steel is not as commonly used as other materials like aluminum or titanium in aerospace, it can still be employed in certain specific applications such as structural components or engine parts where its high strength, durability, and resistance to extreme temperatures are beneficial.

- Q: What is the hardness of the steel sheets?

- The specific grade and treatment of steel can cause variations in the hardness of steel sheets. The Rockwell hardness scale is commonly used to measure the resistance of steel sheets to indentation. The hardness of steel sheets can vary greatly, ranging from soft to extremely hard, and is influenced by factors like carbon content, alloying elements, and heat treatment methods employed in manufacturing. When choosing steel sheets, it is crucial to consider the intended application and desired properties, as the hardness can impact wear resistance, strength, and machinability.

Send your message to us

Corrugated Steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords