Home Depot Checkered Treadplate Aluminium Panel 3003 H22 Sheets of Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Treadplate Aluminium Panel 3003 H22

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Checkered Treadplate Aluminium Panel 3003 H22

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Checkered Treadplate Aluminium Panel 3003 H22

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

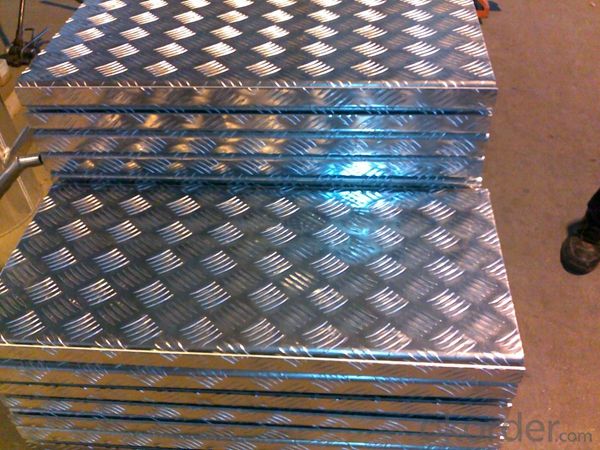

5. Image of Five Bar Treadplate Aluminium Panel 3003 H22 for Tool Box

6. Package and shipping of Checkered Treadplate Aluminium Panel 3003 H22

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Im wondering as to how i darken the slide and frame of an airsoft 1911 pistol. I polished off all the black paint and exposed the chromish aluminum. I have some ideas to darken the metal but not sure. Maybe using olive oil and heating it up but im afraid i might warp the metal. I want it to come out sort of like a greyish gunmetal. Anybody know of a good process to give that worn out war like effect to the gun without painting it?

- Have it powder coated

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- This okorder ... Now for the bad news, most scrap yards DO NOT accept tabs, they try to say it's a lower grade of aluminium, which is not correct, as it is made out of the same sheet of aluminium as the can was. They just don't want to deal with it, or the people who alway's HEARD SOMEWHERE that tabs have some special value. The truth of the matter is that 1 pound of tabs (1,538 +/- tabs) is only worth about 40 cents. That's it, nothing more. Anybody who say's different is stupid, or a liar, there is no third option. Now, if you want to actually make some money, and your willing to do a little work, this is what I do. I take the tabs that i encounter in daily life, remove all damaged tabs (which are donated to McDonald's House Charities), then I sit there with a pair of needle nose pliars, and I remove that little curly thing that holds the tab to the can (which I save, and yes recycle as aluminium , over 220 pounds to date), now, count your tabs out into 1,000 count ziplock baggies. Each of these bags with 26 cents of aluminium will now sell on E-Bay for $4 plus shipping, which is $6.15 per pound. People need them for arts and crafts, I have sold literally millions on OKorder and my web site. The colored tabs are worth about 2 cents each, MONSTER and NOS tabs are worth about 5 cents each.

- Q: How do aluminum sheets perform in terms of water resistance?

- Aluminum sheets generally exhibit excellent water resistance due to their natural oxide layer, which forms a protective barrier against corrosion. This oxide layer prevents water from penetrating the surface, making aluminum sheets highly resistant to water damage and rusting.

- Q: The difference between aluminum plate and aluminum plate

- Aluminum plate is a large piece, the regular width is 90 to 130 centimeters. The aluminum plate is cut aluminum plate, usually according to requirements made several centimeters wide.

- Q: This question asks for methods to determine the reliability of a supplier for aluminum sheets.

- <p>To determine if your supplier is reliable for supplying aluminum sheets, consider the following: Check their track record and customer reviews for consistency and quality. Assess their industry certifications, such as ISO standards, which indicate commitment to quality management. Evaluate their supply chain transparency and their ability to meet delivery timelines. Look into their financial stability to ensure they can sustain operations. Request samples to test the quality of their aluminum sheets. Finally, communicate openly with them to gauge their responsiveness and professionalism.</p>

- Q: Can 101 aluminum sheets be bonded to other materials?

- Indeed, it is possible to bond 101 aluminum sheets with other materials. Aluminum demonstrates remarkable versatility in its capability to be bonded with a vast array of substrates through diverse bonding techniques. Several commonly employed methods for bonding aluminum sheets to other materials comprise adhesive bonding, mechanical fastening, welding, and brazing. The selection of a specific bonding technique hinges upon factors such as the composition of the material to be bonded with aluminum, the desired strength of the bond, and the intended application. Nonetheless, it is crucial to ensure compatibility between the aluminum sheets and the other materials to guarantee the establishment of a robust and long-lasting bond.

- Q: Over 5 billion aluminum cans are recycled each year. If laid end to end, these cans would form a line reaching from?

- No, Ed. 1 billion seconds = 31.69 years, so it was the spring of 1976. Also 1 billion minutes ago = about 1901.3 years ago, so Christ would have been about 100. But I digress... Anyway, let's say the average aluminum can is 4.9 tall (I measured a Coke can). 5 billion cans would be 24.5 billion inches tall. This would be 386,679 miles. This would be from the Earth to the moon (about 250,000 miles) and halfway back again!

- Q: What are the different bending techniques for aluminum sheets?

- There are several bending techniques that can be used for aluminum sheets. Some of the most commonly used techniques include: 1. Air bending: In this technique, a punch is used to apply force on the sheet, which causes it to bend along a straight line. The bend angle is determined by the amount of force applied. 2. Bottom bending: This technique involves clamping the sheet between a bottom tool and a die, while a punch is used to apply force on the sheet from the top. The sheet is bent around the die, resulting in a precise and consistent bend angle. 3. Coining: Coining is a technique in which the sheet is bent using a punch and a die, but with significantly higher force applied compared to other bending techniques. This creates a crisp and sharp bend with minimal springback. 4. Rotary bending: In rotary bending, the sheet is bent around a rotating bending roll. The roll exerts pressure on the sheet, causing it to bend gradually and smoothly. 5. Roll bending: This technique involves passing the aluminum sheet through a series of rollers, which gradually bend the sheet to the desired shape. It is often used for bending large sheets or for creating cylindrical shapes. 6. Press braking: Press braking is a versatile technique that uses a press brake machine to bend the sheet. The machine consists of a punch, a die, and a back gauge, which allows for precise and repeatable bends. Each bending technique has its own advantages and limitations, and the choice of technique depends on factors such as the desired bend angle, the thickness of the sheet, and the overall shape of the final product. It is important to carefully select the appropriate bending technique to ensure the desired result and avoid any defects or damage to the aluminum sheet.

- Q: This question asks for criteria or factors to consider when selecting a high-quality aluminum sheet.

- <p>To choose a quality aluminum sheet, consider the following factors: 1) Thickness and weight, which should meet your specific project requirements. 2) Surface finish, ensuring it's smooth and free from defects. 3) Purity and alloy type, as different alloys have different properties. 4) Certifications, ensuring the sheet meets industry standards. 5) Supplier reputation and customer reviews for reliability. 6) Price, ensuring it's reasonable for the quality. 7) Conductivity and strength, depending on your application. 8) Corrosion resistance, important for longevity. Always inspect the sheet for any visible defects and ensure it's from a reputable supplier.</p>

- Q: What are the different types of coatings applied to aluminum sheet?

- There are several different types of coatings that can be applied to aluminum sheet, each with its own unique properties and benefits. Some of the most common types of coatings include: 1. Anodizing: This is an electrochemical process that forms a protective layer of aluminum oxide on the surface of the sheet. Anodizing provides excellent corrosion resistance and enhances the appearance of the aluminum by creating a durable, colorful finish. 2. Powder Coating: In this process, a dry powder is electrostatically applied to the aluminum sheet and then cured under heat to form a hard, protective coating. Powder coating offers excellent durability, resistance to chipping and scratching, and a wide range of colors and finishes. 3. Paint: Aluminum sheet can also be coated with paint, which provides both aesthetic and protective benefits. The paint can be applied in liquid form and then cured under heat to form a strong, durable coating. Paint coatings offer a wide range of colors and finishes, allowing for customization and design flexibility. 4. Laminating: Laminating involves applying a thin layer of protective film or laminate to the surface of the aluminum sheet. This coating provides additional protection against scratches, abrasion, and UV damage, while also enhancing the appearance of the sheet. 5. Conversion Coatings: Conversion coatings are chemical treatments that convert the surface of the aluminum sheet into a more corrosion-resistant compound. Common conversion coatings include chromate conversion coatings and phosphating, which provide a protective layer that improves adhesion of subsequent coatings. 6. Clear Coatings: Clear coatings, such as lacquer or clear powder coat, can be applied to aluminum sheet to provide protection against oxidation and corrosion while preserving the natural appearance of the metal. Clear coatings are often used when the goal is to maintain the metallic look of the aluminum. These are just a few examples of the different types of coatings that can be applied to aluminum sheet. The choice of coating will depend on factors such as the desired appearance, level of protection required, and the specific application of the aluminum sheet.

Send your message to us

Home Depot Checkered Treadplate Aluminium Panel 3003 H22 Sheets of Aluminum

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords