All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What measures are taken to reduce water and energy consumption during the production of aluminum sheets?

Several measures are implemented to reduce water and energy consumption during the production of aluminum sheets. One common practice is the use of advanced technologies and equipment, such as energy-efficient furnaces and high-pressure water jets, which help minimize energy and water usage. Additionally, recycling and reusing water within the production process is prioritized to reduce overall consumption. Moreover, strict monitoring and optimization of production processes are often adopted to identify and address any inefficiencies that may lead to excessive water and energy usage. Overall, a combination of technological advancements, recycling practices, and process optimization contribute to reducing water and energy consumption in aluminum sheet production.

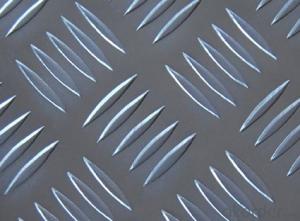

How is the surface finish of aluminum sheets tailored for specific industrial applications?

The surface finish of aluminum sheets is tailored for specific industrial applications by using various techniques such as anodizing, polishing, and coating. Anodizing creates a protective layer on the surface, enhancing corrosion resistance and providing a decorative finish. Polishing improves the smoothness and reflectivity, making it suitable for applications requiring a shiny appearance. Coating, like powder coating or painting, adds an extra layer of protection, improves aesthetics, and can provide specific functionalities like heat resistance or electrical conductivity. Overall, these tailored surface finishes ensure that aluminum sheets meet the specific requirements and performance needs of different industrial applications.

What is the role of aluminum sheets in improving the fuel efficiency of automobiles?

Aluminum sheets play a crucial role in improving the fuel efficiency of automobiles by reducing the overall weight of the vehicle. Aluminum is a lightweight and strong material that helps to decrease the overall mass of the car, which in turn reduces the energy required to propel it. By using aluminum sheets in various parts of the vehicle, such as the body panels, chassis, and engine components, automakers can significantly enhance fuel efficiency and reduce carbon emissions. Additionally, the use of aluminum sheets allows for better aerodynamics, as they can be shaped more efficiently than other materials, further contributing to improved fuel efficiency.

Wholesale Aluminum Sheets from supplier in Peru

Our team is highly knowledgeable about the different types of Aluminum Sheets available and can assist you in selecting the right product for your specific needs. We work closely with our clients to understand their requirements and provide tailored solutions that meet their budget and timeline.

We have established strong partnerships with reputable manufacturers and suppliers, ensuring that we can offer competitive prices and high-quality products. Whether you need Aluminum Sheets for construction, automotive, aerospace, or any other industry, we have the expertise to assist you.

In addition to our sales and procurement services, we also provide technical support to our clients. Our team of engineers is available to answer any questions you may have about the installation, maintenance, or performance of Aluminum Sheets. We can also provide guidance on the best practices for handling and storing the products.

At CNBM, we prioritize customer satisfaction and strive to exceed our clients' expectations. We are committed to delivering exceptional service, reliable products, and timely deliveries. Our goal is to establish long-term partnerships with our clients based on trust, professionalism, and mutual success.

If you are looking for a reliable supplier of Aluminum Sheets in Peru, look no further. Contact us today to discuss your requirements and discover how we can support your projects.

We have established strong partnerships with reputable manufacturers and suppliers, ensuring that we can offer competitive prices and high-quality products. Whether you need Aluminum Sheets for construction, automotive, aerospace, or any other industry, we have the expertise to assist you.

In addition to our sales and procurement services, we also provide technical support to our clients. Our team of engineers is available to answer any questions you may have about the installation, maintenance, or performance of Aluminum Sheets. We can also provide guidance on the best practices for handling and storing the products.

At CNBM, we prioritize customer satisfaction and strive to exceed our clients' expectations. We are committed to delivering exceptional service, reliable products, and timely deliveries. Our goal is to establish long-term partnerships with our clients based on trust, professionalism, and mutual success.

If you are looking for a reliable supplier of Aluminum Sheets in Peru, look no further. Contact us today to discuss your requirements and discover how we can support your projects.