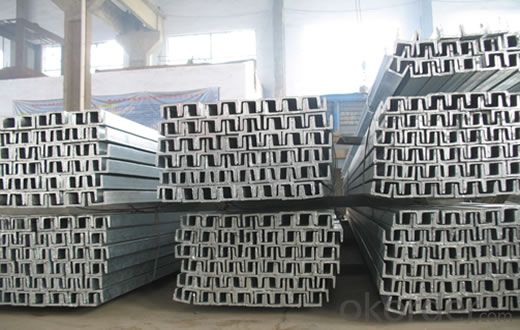

Hot rolled JIS U CHANNEL 50-300MM high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Product Description:

Specifications of MS Channel:

1.We supply high quality MS Channel at reasonable price, including Chinese standard, Japanese standard and so on.

Standard | GB/JIS |

Material Grade | Q235,SS400 |

Technique: | Hot Rolled |

Sizes as per chinese standard: | 50*37*4.5mm - 300*89*11.5mm |

Sizes as per japanese standard: | 50*25*3mm – 200*80*7.5mm |

Length: | 6meter, 9meter, 12meter |

Note: 1.we are also competent to provide our customers other MS Channel based on other sizes according to customer’s requirements.

2. The length of our ms channel could be cut into other meters as per customer’s requirements. For example, the channel in 6meters could be cut into 5.8meters in order to be fit in the 20ft container.

2. The detailed sections of MS Channel as per GB standard.are shown in the table-1:

GB U CHANNEL | Standard | Sectional | Dimension |

| Mass: |

(mm) | (mm) | (mm) | (mm) | ||

50X37 | 50 | 37 | 4.50 | 7.0 | 5.438 |

63X40 | 63 | 40 | 4.80 | 7.5 | 6.634 |

80x43 | 80 | 43 | 5.00 | 8.0 | 8.045 |

100x48 | 100 | 48 | 5.30 | 8.5 | 10.007 |

120x53 | 120 | 53 | 5.50 | 9.0 | 12.059 |

140x58 | 140 | 58 | 6.00 | 9.5 | 14.535 |

140x60 | 140 | 60 | 8.00 | 9.5 | 16.733 |

160x63 | 160 | 63 | 6.50 | 10.0 | 17.240 |

160x65 | 160 | 65 | 8.50 | 10.0 | 19.752 |

180x68 | 180 | 68 | 7.00 | 10.5 | 20.174 |

180x70 | 180 | 70 | 9.00 | 10.5 | 23.000 |

200x73 | 200 | 73 | 7.00 | 11.0 | 22.637 |

200x75 | 200 | 75 | 9.00 | 11.0 | 25.777 |

220x77 | 220 | 77 | 7.00 | 11.5 | 24.999 |

220x79 | 220 | 79 | 9.00 | 11.5 | 28.453 |

250x78 | 250 | 78 | 7.00 | 12.0 | 27.410 |

250x80 | 250 | 80 | 9.00 | 12.0 | 31.335 |

250x82 | 250 | 82 | 11.00 | 12.0 | 35.260 |

280x82 | 280 | 82 | 7.50 | 12.5 | 31.427 |

280x84 | 280 | 84 | 9.50 | 12.5 | 35.823 |

280x86 | 280 | 86 | 11.50 | 12.5 | 40.219 |

300x85 | 300 | 85 | 7.50 | 13.5 | 34.463 |

300x87 | 300 | 87 | 9.50 | 13.5 | 39.173 |

300x89 | 300 | 89 | 11.50 | 13.5 | 43.883 |

Table-1

3. The chemical composition of HR Channel Steel according to Q235B is shown in Table-2.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12-0.20 | 0.3-0.7 | ≦0.045 | ≦0.045 | ≦0.3 |

Table-2

Note: we are able to present our customers relevant SGS test report for chemical composition of HR Channel Steel.

4. The mechanical property of HR Channel Steel according to Q235B is shown in Table-3-1 and Table-3-2

Alloy No | Grade | Yielding Strength Point(Mpa) | |||

Thickness(mm) | |||||

≦16 | >16-40 | >40-60 | >60-100 | ||

≧ | |||||

Q235 | B | 235 | 225 | 215 | 205 |

Table-3-1

Alloy No | Grade | Tensile Strength(Mpa) | Elongation After Fracture(%) | |||

Thickness(mm) | ||||||

≦16 | >16-40 | >40-60 | >60-100 | |||

≧ | ||||||

G235 | B | 375-500 | 26 | 25 | 24 | 23 |

Table-3-2

Note: we are able to present our customers relevant SGS test report for mechanical property of MS Channel as customer’s request.

Applications of MS Channel:

The MS Channel can be applied to construction of warehouses, workshops, sport stadiums and car parks etc.The hot rolled channel steel belongs to carbon structural steel which is applied to in the field of construction and machinery.In details, the hot rolled channel steel is usually used for arch-itechtural structure, and they could be welded in order to support or hang a vari-ety of facilities. They are also usually used in combination with I beam. Generally,the hot rolled channel steel we supply must possess perfect welding property, riveting property and mechanical property and so on.

Package & Delivery of MS Channel:

1.The hot rolled channel steel will be packed in bundle with steel wire at each end of every bundle and color marking in order to help the customer to recognize his goods more easily at sight.

2. And the hot rolled channel steel could be loaded into 20ft or 40ft container, or by bulk cargo.If the weight of each bundle reaches more than 3.5 mt, the loading by break bulk cargo should be choosed.When the weight of each bundle reaches less than 3mt, the loading by container should be choosed.

3.As for the transportaion from mill to loading port, the truck will be usually used. And the maximum quantity for each truck is 40mt.

4.All in all, we could do in accordance with customer's request

- Q: Can steel channels be used in residential construction?

- Indeed, residential construction can incorporate steel channels. These steel channels, which possess a C-shaped cross-section, serve as structural supports made of steel. In the realm of building construction, they are widely utilized for the purpose of providing stability and support to diverse elements like walls, floors, and roofs. The utilization of steel channels in residential construction yields numerous benefits, including their exceptional strength-to-weight ratio, durability, and resistance to fire, rot, and pests. Moreover, they exhibit versatility and find usefulness in a range of applications such as framing, wall studs, and roof trusses. Furthermore, the adaptability of steel channels allows for easy customization and cutting to specific lengths, rendering them suitable for various building designs and requirements.

- Q: What about channel 16?

- Channel steel is a kind of carbon structural steel used for construction and machinery. It is a complex section steel. Its cross section has a groove shape. Channel steel is mainly used in building structure, curtain wall engineering, mechanical equipment and vehicle manufacturing, etc.. In use, it requires better welding, riveting performance and comprehensive mechanical properties. The raw material steel billet for channel steel is carbon or low alloy steel billets with a carbon content of not more than 0.25%. The finished channel steel is delivered by hot forming, normalizing or hot rolling.

- Q: What are the considerations for selecting steel channel sizes?

- When selecting steel channel sizes, there are several considerations that need to be taken into account. These include the load-bearing capacity required for the intended application, the span or distance between supports, the material and weight of the items being supported, and the structural stability needed. Additionally, factors like cost, availability, and compatibility with other building materials may also influence the selection process. Ultimately, the goal is to choose a steel channel size that can effectively support the intended load while ensuring structural integrity and meeting the project's requirements.

- Q: What are the different tolerances for steel channels?

- The different tolerances for steel channels can vary depending on the specific standards and specifications set by the manufacturing industry or the project requirements. Generally, tolerances for steel channels are specified in terms of dimensional measurements such as width, depth, and length. For example, the width and depth tolerances for steel channels are typically defined by a range of acceptable measurements. This range accounts for slight variations in the dimensions of the channel, ensuring that it still satisfies the required specifications while allowing for manufacturing variations. The length tolerance for steel channels can also be specified to ensure that the final product meets the desired length requirements. This could include tolerances for both the overall length of the channel as well as any specific lengths required for certain sections or cuts. In addition to dimensional tolerances, other factors such as surface finish and straightness may also be specified. Surface finish tolerances may dictate the acceptable level of smoothness or roughness on the surface of the steel channel. Straightness tolerances may define how much deviation from a straight line is permissible for the channel. It is important to note that the specific tolerances for steel channels can vary depending on the industry, application, and the standards being followed. Therefore, it is always necessary to refer to the relevant standards or project specifications to determine the precise tolerances for a particular steel channel.

- Q: How do steel channels contribute to the stability of structures?

- Steel channels play a crucial role in enhancing the stability of structures through several means. To begin with, they offer structural support by evenly distributing the load along their length, thereby preventing excessive stress or strain on any specific section of the structure. This, in turn, greatly improves the overall stability of the structure. Moreover, steel channels find extensive application as beams or columns in construction. As beams, they bear the weight of the structure and transmit it to the foundation, ensuring that the structure remains stable and does not collapse under the imposed loads. In the role of columns, steel channels provide vertical support, effectively preventing the structure from buckling or bending under compression forces. Additionally, steel channels can serve as braces, further bolstering the stability of a structure. These braces, which are diagonal members connecting different parts of the structure, enhance its resistance to lateral forces like wind or earthquakes. By adding rigidity and stiffness, steel channels help reduce the risk of structural failure or collapse during such events. Furthermore, steel channels possess exceptional strength and durability, making them exceedingly suitable for supporting heavy loads and enduring extreme conditions. Their resistance to corrosion and deterioration guarantees the long-term stability of the structure. Furthermore, steel channels boast a high load-carrying capacity, enabling the construction of larger and more intricate structures that enjoy heightened stability. In conclusion, steel channels play a significant role in enhancing the stability of structures by providing structural support, evenly distributing loads, bearing weight, preventing buckling or bending, serving as braces, and offering exceptional strength and durability. Their incorporation in construction projects significantly enhances the overall stability and safety of buildings, bridges, and other structures, ensuring their sustained existence and ability to withstand various external forces.

- Q: What is the weight per foot of various steel channel sizes?

- The weight of various steel channel sizes per foot can differ depending on the specific dimensions and thickness of the channel. Steel channels are typically identified by their depth, width, and weight per foot. For instance, a steel channel with a depth of 6 inches and a weight of 8.2 pounds per foot will have an approximate weight of 8.2 pounds per linear foot. Similarly, a steel channel with a depth of 10 inches and a weight of 15.3 pounds per foot will have an approximate weight of 15.3 pounds per linear foot. It is worth noting that these weights are approximate and may slightly vary based on the specific manufacturing process and tolerances. Additionally, different steel alloys or grades may have slightly different weights per foot. Therefore, it is always advisable to refer to the manufacturer's specifications or reference tables for the precise weight per foot of a specific steel channel size.

- Q: Are steel channels suitable for underground applications?

- Yes, steel channels are suitable for underground applications. Steel channels are commonly used in construction and engineering projects due to their high strength and durability. They are able to withstand heavy loads and are resistant to corrosion, making them ideal for underground applications where the environment may be more challenging. Additionally, steel channels can be easily fabricated and customized to meet specific project requirements, allowing for efficient installation and maximum structural integrity underground.

- Q: Can steel channels be used for handrail supports?

- Yes, steel channels can be used for handrail supports. Steel channels are commonly used in construction for their strength and durability, making them an ideal choice for handrail supports. They provide stability and support to the handrail, ensuring its safety and longevity. Additionally, steel channels can be easily customized and fabricated to fit specific handrail designs and requirements.

- Q: What are the different methods of strengthening steel channels?

- There are several methods used to strengthen steel channels, including heat treatment, cold working, and alloying. Heat treatment involves subjecting the steel to high temperatures and then cooling it rapidly, which alters its microstructure and increases its strength. Cold working, on the other hand, involves deforming the steel at room temperature through processes like rolling or drawing, which also enhances its strength. Alloying refers to adding other elements to the steel, such as carbon or chromium, to improve its properties and make it stronger.

- Q: Can steel channels be used in the construction of railings or handrails?

- Steel channels can indeed be utilized in the construction of railings or handrails due to their strength and durability. Being a suitable material for supporting and securing railings or handrails, steel channels are frequently selected. They can be fabricated and installed with ease, offering a robust structure capable of withstanding heavy loads and guaranteeing the safety of individuals who utilize the railing or handrail. Furthermore, steel channels can be designed in diverse shapes and sizes, allowing for flexibility in creating different railing or handrail designs to meet specific architectural needs.

Send your message to us

Hot rolled JIS U CHANNEL 50-300MM high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 20000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords