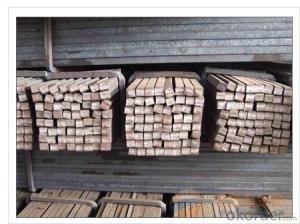

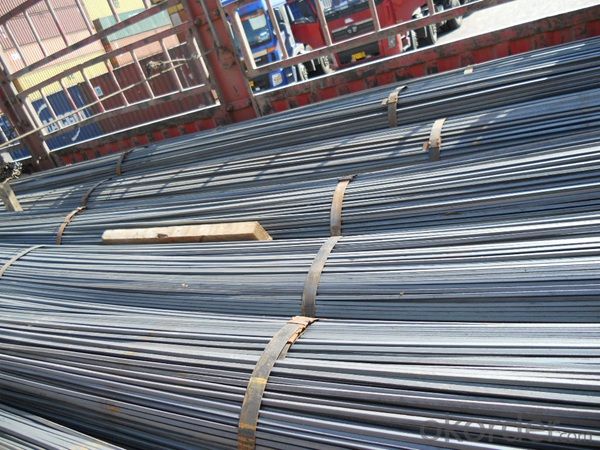

Hot Rolled MS Mild Square Steel Bars for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled MS Mild Square Steel Bars for Strcutures at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Product Advantages:

Hot Rolled MS Mild JIS Steel U Channels for Strcutures are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Standard: GB,

-Grade: Q235 or equivalent.

Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures of Hot Rolled Square Bar:

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Are steel channels suitable for use in storage racks?

- Steel channels are indeed suitable for use in storage racks. Their design is intended to provide structural support and strength, making them an excellent choice for storing heavy items or materials on racks. They possess a high load-bearing capacity, durability, and resistance to bending or warping, all of which contribute to the stability and safety of the storage racks. Additionally, steel channels can be easily customized and adjusted to meet specific storage requirements, making them a versatile option for various storage applications. In conclusion, steel channels are a dependable and effective choice for constructing storage racks.

- Q: How do steel channels contribute to the overall sustainability of the construction industry?

- Steel channels contribute to the overall sustainability of the construction industry by providing a durable and versatile material that can be easily reused and recycled. This reduces the need for new steel production, conserves natural resources, and minimizes waste. Additionally, steel channels offer strength and structural support, allowing for efficient and long-lasting building designs that can withstand various environmental conditions, ultimately reducing the need for frequent repairs or replacements.

- Q: Can steel channels be used in the automotive industry?

- Yes, steel channels can be used in the automotive industry. Steel channels are commonly used in the construction of vehicle frames, chassis, and other structural components due to their strength, durability, and ability to withstand high loads and impacts.

- Q: What are the different types of steel channel supports?

- There are several different types of steel channel supports that are commonly used in construction and engineering projects. These supports are designed to provide structural stability and support for various applications. Some of the different types of steel channel supports include: 1. C-Channel Supports: These supports are shaped like a letter "C" and provide excellent strength and rigidity. They are commonly used in industrial applications such as supporting heavy equipment and machinery. 2. U-Channel Supports: Similar to C-channel supports, U-channel supports are shaped like a letter "U". They are versatile and can be used in a variety of applications, including framing and bracing structures. 3. Back-to-Back Channel Supports: These supports consist of two parallel channels that are welded back-to-back. They offer increased strength and stability and are commonly used in applications that require additional load-bearing capacity. 4. Slotted Channel Supports: Slotted channel supports feature slots along the length of the channel, allowing for easy adjustment and flexibility. They are often used in applications where the position of the support needs to be adjustable. 5. Strut Channel Supports: Also known as strut or framing channel supports, these are designed with specially shaped channels that allow for easy attachment of fittings and accessories. They are commonly used in electrical and mechanical installations. 6. Adjustable Channel Supports: These supports feature telescoping or adjustable sections that allow for height and width adjustment. They are commonly used in applications where the support needs to be adaptable to changing requirements. 7. Stainless Steel Channel Supports: Stainless steel channel supports are made from corrosion-resistant stainless steel, making them ideal for applications in harsh or corrosive environments. These are just a few examples of the different types of steel channel supports available. Each type offers unique features and benefits, allowing for a wide range of applications in various industries. The choice of support will depend on the specific requirements of the project and the load-bearing capacity needed.

- Q: What are the different methods of installation for steel channels?

- Steel channels can be installed using various methods, depending on the desired outcome and specific application. Here are a few common methods: 1. Welding: Welding is a commonly used method for installing steel channels. It involves melting the metal and allowing it to solidify, creating a strong and durable connection. This method is ideal for heavy-duty applications. 2. Bolting: Another installation method is bolting. This involves using bolts, nuts, and washers to secure the steel channel to a surface or structure. Bolting allows for easy disassembly and reassembly, making it suitable for situations where adjustments or modifications may be required. 3. Adhesive bonding: Adhesive bonding can be used to install steel channels in some cases. Industrial adhesives or epoxy are used to bond the channel to another surface, providing a reliable connection. It is often used in conjunction with other methods like bolting or welding. 4. Fasteners: Steel channels can also be installed using screws, nails, or rivets. This method is typically used for temporary or lightweight applications, as it may not provide as strong of a connection as welding or bolting. 5. Interlocking systems: Some steel channels are designed with interlocking systems that allow for easy connection and secure installation without the need for additional methods. These systems feature grooves or slots that allow the channels to fit together like puzzle pieces, creating a stable connection. To determine the most appropriate installation method for steel channels, it is important to consider the specific requirements of the application and consult with professionals or refer to industry guidelines.

- Q: What are the different industry standards for steel channels?

- There are several industry standards for steel channels, which are used to ensure consistency and quality in the manufacturing and usage of these structural components. Some of the commonly recognized standards for steel channels include: 1. American Standard Channels (C) - These steel channels are defined by the American Iron and Steel Institute (AISI) and are widely used in North America. The dimensions, properties, and tolerances for American Standard Channels are specified in ASTM A6/A6M. 2. European Standard Channels (UPN) - These steel channels are defined by the European Committee for Standardization (CEN) and are prevalent in Europe. The dimensions, properties, and tolerances for European Standard Channels are specified in EN 10365. 3. British Standard Channels (BS) - These steel channels are defined by the British Standards Institution (BSI) and are commonly used in the United Kingdom. The dimensions, properties, and tolerances for British Standard Channels are specified in BS 4-1. 4. Japanese Standard Channels (JIS) - These steel channels are defined by the Japanese Industrial Standards (JIS) and are widely used in Japan and other Asian countries. The dimensions, properties, and tolerances for Japanese Standard Channels are specified in JIS G 3192. 5. Australian/New Zealand Standard Channels (AS/NZS) - These steel channels are defined by the Standards Australia and Standards New Zealand organizations and are commonly used in Australia and New Zealand. The dimensions, properties, and tolerances for Australian/New Zealand Standard Channels are specified in AS/NZS 3679.1. It is important to note that these standards may slightly differ in terms of dimensional tolerances, chemical composition, mechanical properties, and designations. Therefore, understanding and adhering to the appropriate industry standard is crucial for ensuring compatibility and compliance with the specific requirements of a particular project or application involving steel channels.

- Q: How to install solid wood fence at the gate of the channel gate? Specifically, how to fix the solid wood column to the channel steel? (a gypsum board spread over a channel

- The channel above several holes, screws first. A 6 * 12 square, you can freely install wooden fence.

- Q: Can steel channels be used for framing walls?

- Yes, steel channels can be used for framing walls. They provide a strong and durable framework for constructing walls and can be an excellent alternative to traditional wood framing. Steel channels offer superior strength and resistance to warping, shrinking, and termite damage. Additionally, they are lightweight and easy to work with, making them a popular choice in many construction projects.

- Q: How do steel channels perform under snow loads?

- Steel channels perform well under snow loads due to their high strength and stiffness. The structural integrity and load-bearing capacity of steel channels allow them to effectively resist the weight and pressure exerted by snow, making them a reliable choice for withstanding snow loads.

- Q: Channel 10, 6 meters long, two ends fixed, how much weight can the middle bear?

- Under the maximum bending moment calculation formula: M=1/8GL?? -1/8gL??, (L=600cm, G: the calculation of the maximum uniform load, G: ibid.)

Send your message to us

Hot Rolled MS Mild Square Steel Bars for Strcutures

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords