Hot rolled square steel; square steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

Specifications of Hot-rolled Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

-Chemical Composition:

Standard | Grade | Element (%) | ||||

C | Mn | S | P | Si | ||

GB | Q195 | 0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 |

GB | Q235B | 0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 |

-Mechanical Properties:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

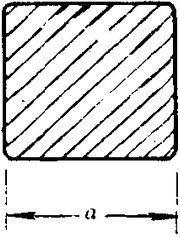

Measures of Hot-rolled Square Steel Bar (Big measures):

(Section of Hot-rolled Square Steel Bar)

-Length of a side and Theoretical weight of Square Bar (Big measures).

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

53 | 22.05 | 80 | 50.24 |

56 | 24.61 | 85 | 56.72 |

60 | 28.26 | 90 | 63.59 |

63 | 31.16 | 95 | 70.85 |

70 | 38.49 | 100 | 78.50 |

75 | 44.16 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

Usage/Applications of Hot-rolled Square Steel Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Packaging & Delivery of Hot-rolled Square Steel Bar:

-Packing Detail:

1, The products can be packed in bundles by steel wires.

2, The weight of each bundle no exceed normally 3 tons.

-Marks: We make tag marks and color marks for each bundle. The tag marks with white background and red company log will be tied up to each bundle. The information is usually including basic information of company and products like product name, specification, etc...and other information required by customers. As for color marks, we will paint both ends of each bundles to make sure that it will be more convenient for customers to distinguish theme from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

-The payment terms will be written in contraction detailedly.

- Q: How do you use a steel square to lay out a birdsmouth cut?

- In order to lay out a birdsmouth cut using a steel square, the dimensions required for the cut must first be determined. A birdsmouth, which is a notch or cutout made on the top edge of a rafter to securely rest on a wall or supporting structure, can be achieved by following these step-by-step instructions: 1. Determine the desired depth of the birdsmouth cut on the rafter and mark it accordingly. Typically, this is based on the thickness of the supporting structure it will be placed on. 2. Align the longer leg (blade) of the steel square with the edge of the rafter, ensuring that the shorter leg (tongue) extends beyond the rafter's width. 3. Slide the square along the rafter until the desired length of the birdsmouth cut is achieved. The point where the blade meets the rafter edge should align with the marked depth. 4. Securely hold the square in position and use a pencil or scribe to trace along the tongue's edge. 5. Without moving the square, rotate it so that the tongue aligns with the rafter's edge and the blade extends beyond the width of the rafter. 6. Slide the square along the rafter until the desired cut length is reached, ensuring that the point where the tongue meets the rafter edge aligns with the marked depth. 7. Once again, securely hold the square in place and use a pencil or scribe to trace along the blade's edge. 8. The resulting traced lines will form an L-shape on the rafter, outlining the birdsmouth cut. 9. Carefully use a saw to cut along the traced lines, ensuring to stay within the lines and maintain the desired dimensions. By following these instructions, a steel square can be effectively utilized to lay out and cut a birdsmouth, resulting in a precise fit for the rafter on the supporting structure.

- Q: Can a steel square be used for checking the squareness of corners?

- Yes, a steel square can be used for checking the squareness of corners.

- Q: Can a steel square be used for laying out a garden bed?

- Indeed, the utilization of a steel square is viable for the establishment of a garden bed. This multifunctional instrument is capable of measuring and delineating right angles, a crucial aspect in establishing accurate and linear garden bed boundaries. Regardless of whether you intend to construct a rectangular or square garden bed, the application of a steel square can guarantee precise alignment of the corners. Furthermore, the straight edge of the steel square can serve as a reliable reference for producing straight lines and edges within your garden bed. In conclusion, the utilization of a steel square facilitates the creation of orderly and symmetrical garden beds.

- Q: How do you use a steel square to ensure the correct angle for a dovetail joint?

- In order to achieve the correct angle for a dovetail joint, it is necessary to follow several straightforward steps. To begin, determine the desired angle for the dovetail joint. Typically, this angle is either 1:8 or 1:6, with the 1:8 ratio being more commonly used. Following that, position the steel square along the edge of the board where the dovetail joint will be cut. Ensure that the longer side of the square is aligned with the board's edge, while the shorter side is perpendicular to it. Subsequently, use a pencil or marking knife to draw a line along the shorter side of the square. This line will serve as a reference when cutting the dovetail joint. For a 1:8 angle, the line should be 1/8th of an inch away from the board's edge. Similarly, for a 1:6 angle, the line should be 1/6th of an inch away from the edge. You can then utilize this line as a guide when cutting the dovetail joint. Each time you need to mark another cut or take a measurement, position the square along the board's edge to ensure accuracy. By employing a steel square in this manner, you can guarantee that the dovetail joint possesses the correct angle, resulting in a sturdy and precise joint. Always remember to double-check your measurements and conduct test cuts before finalizing the joint.

- Q: Can a steel square be used for raised bed layout and construction?

- Yes, a steel square can definitely be used for raised bed layout and construction. Its sturdy and durable nature makes it an ideal tool for measuring and marking straight lines and angles, ensuring precise and accurate construction of raised beds.

- Q: How do you use a steel square for marking stair newel post angles?

- In order to mark stair newel post angles using a steel square, it is necessary to follow a series of steps. Initially, it is important to possess a steel square, a tool in the shape of a triangle with measurements indicated on its edges. To begin, place the steel square against the newel post, making sure that one edge of the square is aligned with the surface of the post. Ensure that the square is firmly held in place and flush against the post. Subsequently, locate the desired angle on the steel square. The square will display various angle measurements, such as 45 degrees or 90 degrees. Select the appropriate angle based on your specific needs. Upon identifying the desired angle, use a pencil or marker to trace along the edge of the steel square that corresponds to that angle. This will transfer the angle onto the newel post. Proceed to repeat this process for any additional angles that need to be marked on the newel post, utilizing the suitable edges of the steel square. Once the angles have been marked, it is advisable to verify the accuracy and alignment by employing a protractor or another measuring tool. This step will guarantee that the newel post is cut and installed correctly. By employing a steel square to mark stair newel post angles, precise and consistent measurements can be achieved, resulting in a professional installation. Always remember to double-check measurements before making any cuts to ensure accuracy.

- Q: Can a steel square be used for marking out half-blind dovetail joints?

- Indeed, half-blind dovetail joints can be marked out using a steel square. A steel square, known for its versatility, is frequently employed in woodworking to mark and measure right angles. Its capability to deliver accurate and precise measurements makes it ideal for denoting the angles and dimensions essential for half-blind dovetail joints. Nevertheless, it is crucial to ensure the proper alignment and secure placement of the steel square when marking out the joints to attain precise outcomes.

- Q: Can a steel square be used for metalworking tasks?

- Yes, a steel square can be used for metalworking tasks. A steel square, also known as a framing square or carpenter's square, is a versatile tool that can be used for measuring, marking, and checking right angles in metalworking projects. It is commonly used for layout work, marking reference lines, and ensuring accurate angles while cutting or fabricating metal pieces.

- Q: What are the common mistakes to avoid when using a steel square?

- Some common mistakes to avoid when using a steel square include not checking for accuracy before use, not securely holding the square against the workpiece, using the wrong side of the square for specific measurements, not properly aligning the square with the edges of the workpiece, and not ensuring the square is perpendicular or square to the workpiece.

- Q: Round and square steel which is strong

- From the round and square steel specifications and appearance quality of the steel, 1. force large contact surface and relatively small pressure, 2. and three provide support force and the force behind. The force contact surface of round steel is very strong.

Send your message to us

Hot rolled square steel; square steel bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords