HR Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of HR Square Steel:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q195 or equivalent.

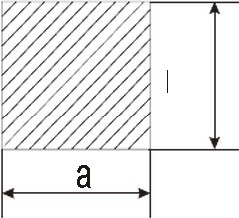

(The section of Square Steel)

Some details of HR Square Steel:

-List 1. Chemical Composition.

|

Standard |

Grade |

Element (%) | ||||

|

GB |

Q195 |

C |

Mn |

S |

P |

Si |

|

0.06~0.12 |

0.25~0.50 |

≤0.050 |

≤0.045 |

≤0.30 | ||

-List 2. Physical Properties

|

Grade |

Yield Point Δs/MPa |

Tensile Strength |

Elongation δ5% | ||

|

Steel diameter(mm) |

Steel diameter(mm) | ||||

|

≤16 |

16~40 |

≤16 |

16~40 | ||

|

≥ |

≥ | ||||

|

Q195 |

195 |

185 |

315~390 |

33 |

32 |

-List 3.The length of a side and the theoretical weight of HR Square Steel.

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

6 |

0.283 |

32 |

8.04 |

|

7 |

0.385 |

*33 |

8.55 |

|

8 |

0.502 |

34 |

9.07 |

|

9 |

0.636 |

*35 |

9.62 |

|

10 |

0.785 |

36 |

10.17 |

|

11 |

0.950 |

38 |

11.24 |

|

12 |

1.13 |

40 |

12.56 |

|

13 |

1.33 |

42 |

13.85 |

|

14 |

1.54 |

45 |

15.90 |

|

15 |

1.77 |

48 |

18.09 |

|

16 |

2.01 |

50 |

19.63 |

|

17 |

2.27 |

53 |

22.05 |

|

18 |

2.54 |

*55 |

23.6 |

|

19 |

2.82 |

56 |

24.61 |

|

20 |

3.14 |

*58 |

26.4 |

|

21 |

3.46 |

60 |

28.26 |

|

22 |

3.80 |

63 |

31.16 |

|

*23 |

4.15 |

*65 |

33.17 |

|

24 |

4.52 |

*68 |

36.3 |

|

25 |

4.91 |

70 |

38.49 |

|

26 |

5.30 |

75 |

44.16 |

|

*27 |

5.72 |

80 |

50.24 |

|

28 |

6.15 |

85 |

56.72 |

|

*29 |

6.60 |

90 |

63.59 |

|

30 |

7.06 |

95 |

70.85 |

|

*31 |

7.54 |

100 |

78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 4. The allowed tolerance of HR Square Steel:

|

Length of a side(mm) |

Allowed Tolerance | ||

|

Group1 |

Group2 |

Group3 | |

|

5.5~7 |

±0.20 |

±0.30 |

±0.40 |

|

7~20 |

±0.25 |

±0.35 |

±0.40 |

|

20~30 |

±0.30 |

±0.40 |

±0.50 |

|

30~50 |

±0.40 |

±0.50 |

±0.60 |

|

60~80 |

±0.60 |

±0.70 |

±0.80 |

|

80~110 |

±0.90 |

±1.0 |

±1.1 |

|

110~150 |

±1.2 |

±1.3 |

±1.1 |

|

150~190 |

―― |

―― |

±2.0 |

|

190~250 |

―― |

―― |

±2.5 |

Usage/Applications of HR Square Steel:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of HR Square Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of HR Square Steel:

- Q: How do you use a steel square to measure the width of a door jamb?

- To use a steel square to measure the width of a door jamb, place the square against the edge of the jamb and extend one arm of the square until it reaches the opposite edge of the jamb. Take note of the measurement displayed on the square's ruler, which represents the width of the door jamb.

- Q: Can a steel square be used for checking the levelness of a miter saw base?

- Indeed, the levelness of a miter saw base can be assessed using a steel square. This tool proves highly useful in verifying the accuracy and levelness of diverse surfaces, such as the base of a miter saw. By simply positioning the steel square against the miter saw base surface, it becomes effortless to determine its levelness. In the event that the saw base is not level, necessary adjustments can be executed to ensure the execution of precise and accurate cuts. Nevertheless, it is crucial to bear in mind that although a steel square can offer a rough approximation of the levelness, it may not match the precision achieved with a precision-leveling tool.

- Q: How do you use a steel square to measure and mark out angled cuts?

- To use a steel square for measuring and marking out angled cuts, first, align one edge of the square with the edge of the material to be cut. Next, adjust the square to the desired angle by pivoting it along the edge that is aligned with the material. Once the square is at the correct angle, use a pencil or scribe to mark the cut line along the edge of the square. Finally, carefully cut along the marked line following the angle indicated by the square.

- Q: Can a steel square be used for checking the squareness of deck posts?

- Deck posts can be checked for squareness using a steel square. A steel square, also called a framing square or carpenter's square, is a versatile tool commonly used in carpentry and construction. It consists of a long arm and a shorter arm that form a right angle. One of its main purposes is to ensure that corners and angles are perfectly square. To check the squareness of deck posts with a steel square, follow these steps: 1. Place the steel square against one side of the deck post, making sure that the long arm rests against the post while the shorter arm extends vertically. 2. Check the alignment of the shorter arm with the adjacent side of the deck post. If the post is square, the shorter arm of the steel square should be flush against the post without any gaps or overlaps. 3. Repeat this process on all four sides of the deck post to confirm its squareness. If the steel square consistently aligns flush with all sides, the post can be considered square. 4. If the steel square does not align properly or there are gaps or overlaps, make adjustments to the post. This may involve repositioning or remeasuring the post to ensure it is at a right angle to the deck surface. It is important to note that while a steel square is an effective tool for checking the squareness of deck posts, it should be used in conjunction with other methods, such as measuring diagonals or using a level, to ensure accurate and precise results.

- Q: What are the common accessories that come with a steel square?

- The common accessories that come with a steel square typically include a protective case or sheath, an instruction manual or guide booklet, and sometimes a carpenter's pencil or marking tool.

- Q: How do you use a steel square to lay out a parallelogram base?

- To use a steel square to lay out a parallelogram base, start by aligning one edge of the steel square with the desired length of one side of the parallelogram. Then, use a pencil to mark the end point of that side. Next, rotate the steel square 90 degrees and align it with the desired width of the parallelogram. Finally, use the edge of the steel square to draw a line connecting the marked end point of the first side to create the base of the parallelogram.

- Q: Can a steel square be used for constructing stairs?

- Certainly! When it comes to constructing stairs, a steel square proves to be quite handy. Known as a framing square or carpenter's square, this versatile tool is frequently employed in the realms of construction and woodworking. Its primary function revolves around gauging and delineating right angles, which makes it an excellent choice for precisely laying out stair stringers, calculating the rise and run of each step, and guaranteeing accuracy in cuts. Steel, being both durable and strong, renders it a dependable material for crafting stairs that can endure heavy foot traffic and offer steadfast stability for an extended period.

- Q: Can a steel square be used for door and window installation?

- Yes, a steel square can be used for door and window installation. Steel squares are commonly used in construction and carpentry for measuring and marking angles, ensuring accurate and precise installation.

- Q: Can a steel square be used for laying out roof rafters?

- Yes, a steel square can be used for laying out roof rafters. Steel squares are commonly used by carpenters and roofers for measuring and marking angles when constructing roofs. They are durable and provide accurate measurements, making them suitable for the task of laying out roof rafters.

- Q: What are the alternative tools for a steel square?

- Some alternative tools for a steel square include a combination square, framing square, bevel gauge, or a digital angle finder.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

HR Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords