Mild Steel Square Billet for Section Steel Production in Factory Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Mild Steel Square Billet description:

Mild steel square billet is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, mild steel square billet is still in the form of a metal bar or rectangle. Small sizes of mild steel square billet are used in ship building.

2. Main Features of Mild Steel Square Billet:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

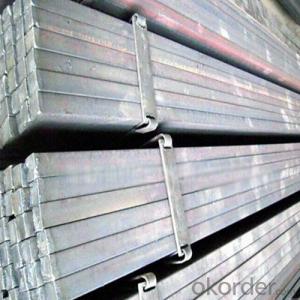

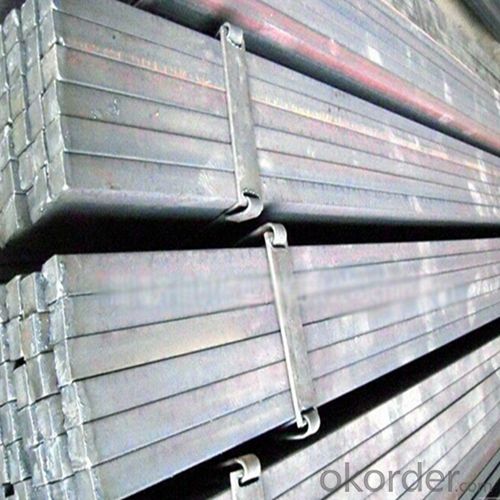

3. Mild Steel Square Billet Images:

4. Mild Steel Square Billet Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How do you use a steel square for marking roof valley angles?

- In order to mark roof valley angles using a steel square, there are a few simple steps that need to be followed. Firstly, it is important to ensure that the steel square is clean and free from any dirt or debris that could affect its accuracy. Next, position the steel square against the roof valley in the desired location, ensuring that it is properly aligned with both the edge of the roof and the valley line. Once the steel square is in place, use a pencil or marker to trace along the edge of the steel square onto the roof surface. This will create a clear marking indicating the angle of the roof valley. If there is a need to mark multiple angles along the valley, simply adjust the position of the steel square accordingly and repeat the tracing process. Using a steel square to mark roof valley angles is a precise and effective method, guaranteeing accuracy and consistency in the markings. It is crucial to take the time to double-check the measurements to ensure that the markings are correct before proceeding with any roofing work.

- Q: How do you choose the right size of steel square for a project?

- When choosing the right size of steel square for a project, there are a few factors to consider. Firstly, you need to assess the scale and scope of your project. Determine the size and weight requirements of the steel square based on the load it will bear and the structural integrity it needs to provide. This will depend on the specific application, such as construction, fabrication, or general DIY work. Next, consider the dimensions of the components or materials that will interact with the steel square. It should be large enough to accommodate the size of these elements, ensuring a proper fit and functionality. For instance, if you are using the steel square as a support beam, it should be wide and thick enough to provide adequate strength. Additionally, think about the physical space in which the project will take place. If you have limited clearance or tight quarters, a smaller-sized steel square might be more suitable. Consulting structural engineering tables and industry standards can also be helpful in determining the appropriate size of a steel square for your project. These resources provide guidelines on load-bearing capacities and recommended sizes for various applications. Lastly, it's always a good idea to seek advice from professionals or experienced individuals in the field. They can offer insights based on their expertise and help you select the right size of steel square for your specific project requirements.

- Q: The difference between cold and hot galvanized steel hollow where

- Cold rolling process is: the strip through the mold, pipeline bending forming, and then through the automatic welding, the welding joints, and then polished, galvanized, also called seamed tube.

- Q: How do you use a steel square to determine angles for chair legs?

- To use a steel square for determining angles for chair legs, you would place the square against the leg and adjust it until the blade aligns with the desired angle. Once aligned, you can then mark the leg using the square as a guide and proceed with cutting or shaping the leg accordingly.

- Q: Can a steel square be used for checking the squareness of a bandsaw blade?

- No, a steel square cannot be used for checking the squareness of a bandsaw blade as a steel square is designed for measuring right angles in woodworking and construction, while a bandsaw blade requires specialized tools and techniques for proper alignment.

- Q: Can a steel square be used for raised bed layout and construction?

- Yes, a steel square can be used for raised bed layout and construction. A steel square, also known as a framing square or a carpenter's square, is a versatile tool commonly used in woodworking and construction projects. Its L-shaped design with a long blade and a shorter tongue allows for accurate measurements, right angles, and various layout tasks. When it comes to raised bed layout and construction, a steel square can be particularly useful for ensuring straight lines, square corners, and consistent measurements. It can help in marking the boundaries of the raised bed, determining the angles for corner joints, and checking for levelness. Additionally, a steel square can assist in cutting and shaping the lumber or other materials used for the construction of the raised bed. Its straight edge can be aligned with the desired cut line, providing a guide for precise and straight cuts. This helps in achieving a professional and clean finish for the raised bed. Overall, a steel square is a valuable tool for raised bed layout and construction due to its accuracy, versatility, and ability to assist in various tasks involved in building a raised bed.

- Q: Can a steel square be used for measuring pipe diameters?

- No, a steel square cannot be used for measuring pipe diameters accurately. A steel square is primarily used for measuring right angles and checking the straightness of edges. It consists of a long steel ruler with a perpendicular arm called a tongue. While it can be helpful in some construction and woodworking tasks, it is not designed for measuring pipe diameters. To accurately measure the diameter of a pipe, one would typically use a caliper, tape measure, or a specialized tool such as a pipe diameter tape. These tools are specifically designed to measure the circumference or diameter of cylindrical objects like pipes.

- Q: How do you choose the right size of a steel square?

- When it comes to selecting the appropriate size for a steel square, several factors should be taken into account. To begin with, the nature of the task or project that the square will be utilized for must be considered. By determining the dimensions of the material at hand and the measurements that need to be taken, you can get a sense of the minimum size that might be necessary. In addition, your own comfort and ease of use should be factored in. Although a larger square may offer increased stability and accuracy, it can also be heavier and more challenging to handle. If you anticipate utilizing the square for extended periods or in confined spaces, a smaller size may be more suitable. Moreover, the level of precision and accuracy required should be contemplated. Smaller squares are generally more precise and well-suited for intricate tasks, while larger squares excel in general layout and framing endeavors. Lastly, your budget and the range of options available should be taken into consideration. Steel squares are available in various sizes, and the cost varies accordingly. Striking a balance between your needs and affordability is crucial. Ultimately, the most appropriate size for a steel square will depend on the specific requirements of your project, your personal comfort, and the level of accuracy necessitated. By taking these factors into account, you can make an informed decision and select the size that best suits your needs.

- Q: How do you use a steel square for marking tenon and mortise joints?

- To mark tenon and mortise joints, there are a few steps that need to be followed. First, make sure you have a steel square that has clear and accurate markings. Next, take the wood piece you want to mark and position it in the desired orientation for the joint. Align one end of the steel square with the edge of the wood, depending on the type of joint you are making. Once the square is in the correct position, use a pencil or marking knife to trace along the edge of the square onto the wood. This will create a precise and straight line, which will help you accurately cut or chisel the mortise or tenon. For marking tenon joints, flip the wood and repeat the process on the other end. Be sure to align the square with the previously marked line to maintain consistency and accuracy. Furthermore, the steel square can also be used to mark the depth of the mortise or tenon. Simply slide the square along the length of the wood and mark the desired depth on the side of the wood using the square's markings. Using a steel square for marking tenon and mortise joints is a straightforward and effective method to achieve precise and clean joints. It preserves the integrity of the joint and guarantees a strong and durable connection between the two wood pieces.

- Q: Can a steel square be used for measuring the width of a door frame?

- Indeed, one can employ a steel square to gauge the breadth of a door frame. The steel square, a multifunctional measuring instrument frequently utilized in carpentry and construction endeavors, encompasses a level metal blade accompanied by a perpendicular handle, thus forming a right angle. By situating the blade of the steel square against the internal perimeters of the door frame, one can obtain an exact measurement of the width. The right angle of the square serves to guarantee a perpendicular and accurate measurement.

Send your message to us

Mild Steel Square Billet for Section Steel Production in Factory Line

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords