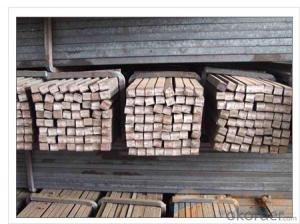

Carbon Steel Hot Rolled Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Square Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

1. Chinese standard steel bar is often used where large amounts of steel need to be formed, for example as structural steel.

2. And we can use this kind of product on the performance of the mechanical parts if the demand is not very high.

3. Steel round bar is used in construction and a large number of architectural and engineering structures.

Product Advantages:

OKorder's Square Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Grade: Q195, Q235, Q345

2. Diameter: 6mm-150mm

3. Length: 6m, 9m, 12m or as customer’s request

4. Tolerance: Within ±5% for weight; ±2mm for diameter

5. Note: The price can be better is the quantity is good

6. Chemical composition

Alloy No | Element (%) | ||||

C | Mn | S | P | Si | |

Q195 | 0.06-0.12 | 0.25 | ≤0.05 | ≤0.045 | ≤0.3 |

Q235 | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Q345 | ≤0.2 | 1.00-1.60 | ≤0.045 | ≤0.045 | ≤0.55 |

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What makes stainless steel stainless?

A3: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: How do you use a steel square to measure and mark 60-degree angles?

- To use a steel square to measure and mark 60-degree angles, you can follow these steps: 1. Ensure that your steel square is clean and free from any dirt or debris that could affect the accuracy of your measurements. 2. Identify the 45-degree angle on your steel square. This is typically marked as a right angle (90 degrees) with an additional line running diagonally through it. 3. Place the steel square on your workpiece or material, aligning one edge of the square with the edge of the material. 4. Rotate the square until the 45-degree angle is aligned with the edge of the material. This will create a 45-degree angle from the edge of the material. 5. To create a 60-degree angle, you need to mark a point that is 15 degrees away from the 45-degree angle. 6. Using a protractor or any other measuring tool, measure 15 degrees from the 45-degree angle in the direction you want your 60-degree angle to be. 7. Once you have identified the 15-degree point, make a small mark on your material at that location. 8. Connect the mark you made to the edge of the material using a straight edge or ruler. This line will represent your 60-degree angle. 9. Double-check your measurements and markings to ensure accuracy. By following these steps, you can effectively use a steel square to measure and mark 60-degree angles. It is important to note that practice and precision are key to achieving accurate results when working with angles.

- Q: Can a steel square be used for checking the squareness of a hand saw blade?

- No, a steel square cannot be used for checking the squareness of a hand saw blade. A steel square is primarily used for measuring and marking right angles, whereas checking the squareness of a hand saw blade requires a specialized tool called a saw set or a square filing guide. These tools are specifically designed to ensure the correct angle and squareness of the teeth on a hand saw blade for optimal cutting performance.

- Q: Can a steel square be used for framing a wall?

- Yes, a steel square can be used for framing a wall. A steel square, also known as a framing square or a carpenter's square, is a versatile tool that can be used for a variety of framing and layout tasks in construction. It has a right-angle shape with a long blade and a shorter tongue, and is typically made of steel or aluminum. When framing a wall, a steel square can be used to ensure accurate and square corners. It can help in marking and measuring cuts for studs, rafters, and other framing members. The long blade of the square can be used to mark straight lines and check for straightness and levelness of walls and other surfaces. In addition to framing walls, a steel square can also be used for other framing tasks such as laying out roof rafters, cutting stair stringers, and checking for squareness in various construction projects. Its durable and sturdy construction makes it a reliable tool for both professional contractors and DIY enthusiasts. However, it is important to note that while a steel square is a valuable tool for framing walls, it may not be the only tool needed. Other tools such as a level, tape measure, and power tools may also be necessary for a successful framing project.

- Q: Are steel squares resistant to rust and corrosion?

- Steel squares, in general, have the ability to resist rust and corrosion. They are typically manufactured using stainless steel, which contains a significant amount of chromium. This element plays a crucial role in providing stainless steel with its corrosion-resistant properties. By forming a protective layer, known as a passive film, chromium prevents oxygen from reaching the underlying metal, thus hindering the formation of rust. Nevertheless, it is worth noting that the degree of resistance to rust and corrosion may vary based on the quality of the steel employed. Stainless steel squares of higher quality will exhibit greater resistance to rust and corrosion compared to those of lower quality. Furthermore, the maintenance and care dedicated to the steel squares can also impact their resistance. Consistent cleaning and proper storage practices contribute to prolonging their lifespan and preserving their resistance to rust and corrosion.

- Q: Can a steel square be used for checking the plumbness of a post hole?

- Yes, a steel square can be used for checking the plumbness of a post hole. A steel square is a versatile tool that is commonly used in woodworking and construction. It has a 90-degree angle that can be aligned with the sides of the post hole to check for plumbness. By placing the steel square against the sides of the hole, one can determine if the walls are straight and vertical. If the steel square does not align properly, adjustments can be made to ensure the post is set in a plumb position. However, it's important to note that while a steel square can be helpful for initial checking, a more accurate measurement can be obtained by using a plumb bob or a level to ensure the post is perfectly vertical.

- Q: Can a steel square be used for checking the squareness of a belt sander table?

- Yes, a steel square can be used for checking the squareness of a belt sander table. A steel square is a precision measuring tool that is typically used to check the squareness of corners or edges in woodworking and metalworking projects. To check the squareness of a belt sander table, you can place the steel square against the edge of the table and ensure that it is perfectly perpendicular to the table surface. This will help determine if the table is properly aligned and square, which is crucial for achieving accurate and even sanding results.

- Q: How the two square welded T shape angle and turning angle, how to improve the speed and quality?

- Also, I do not know whether you are welding stainless steel or iron, the novice can press the method to do, but ripe workers are visual, direct welding, of course, visual accuracy will always be a little worse,

- Q: Can a steel square be used for drywall corner layout?

- Yes, a steel square can be used for drywall corner layout. A steel square is a versatile tool that can be used for measuring and marking angles accurately, making it suitable for determining the correct angles for drywall corners.

- Q: Can a steel square be used for roof truss layout and construction?

- Yes, a steel square can be used for roof truss layout and construction. A steel square, also known as a framing square or carpenter's square, is a versatile tool that is commonly used in the construction industry for various tasks, including roof truss layout. A steel square consists of two arms that meet at a right angle, forming a 90-degree corner. One arm is longer than the other, typically 24 inches long, and is used for measuring and marking straight lines. The shorter arm, usually 16 inches long, is used for measuring and marking angles. When it comes to roof truss layout, a steel square can be used to determine and mark the angles for the truss members. It can be used to layout the pitch or slope of the roof, ensuring that the trusses are properly aligned and positioned. Additionally, a steel square can also be used for cutting and marking the truss members. It can be used to mark the angles for the cuts, ensuring that the truss members fit together accurately. The longer arm can be used to measure and mark the length of the truss members, ensuring that they are cut to the correct size. Overall, a steel square is a valuable tool for roof truss layout and construction. Its versatility and accuracy make it an essential tool for carpenters and construction professionals working on roof truss projects.

- Q: Can a steel square be used for measuring curved surfaces?

- No, a steel square cannot be used for measuring curved surfaces. A steel square, also known as a framing square or carpenter's square, is designed for measuring and marking straight lines and right angles. It consists of a long blade and a shorter tongue that are perpendicular to each other. The straight edges of a steel square make it ideal for tasks such as checking corners for squareness or marking 90-degree angles. However, due to its rigid shape, it is not suitable for measuring or marking curved surfaces. For measuring curves, flexible measuring tools such as a flexible tape measure or a contour gauge would be more appropriate.

Send your message to us

Carbon Steel Hot Rolled Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords