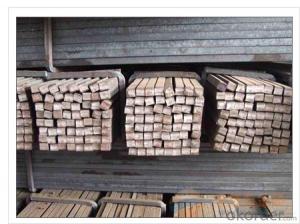

Hot Rolled Low Carbon Steel Square Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Low Carbon Steel Square Bars at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Low Carbon Steel Square Bars are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot Rolled Low Carbon Steel Square Bars are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

| SQUARE BAR | |

| SIZE a(mm) | theoretical kg/m |

| 5.5 | 0.237 |

| 6 | 0.283 |

| 7 | 0.385 |

| 8 | 0.502 |

| 9 | 0.636 |

| 10 | 0.785 |

| 11 | 0.95 |

| 12 | 1.13 |

| 13 | 1.33 |

| 14 | 1.54 |

| 15 | 1.77 |

| 16 | 2.01 |

| 17 | 2.27 |

| 18 | 2.54 |

| 19 | 2.83 |

| 20 | 3.14 |

| 21 | 3.46 |

| 22 | 3.8 |

| 24 | 4.52 |

| 25 | 4.91 |

| 26 | 5.31 |

| 28 | 6.15 |

| 30 | 7.06 |

| 32 | 8.04 |

| 34 | 9.07 |

| 36 | 10.2 |

| 38 | 11.3 |

| 40 | 12.6 |

| 42 | 13.8 |

| 45 | 15.9 |

| 48 | 18.1 |

| 50 | 19.6 |

| 53 | 22 |

| 56 | 24.6 |

| 60 | 28.3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How many tons of steel products could be loaded in containers?

A3: Usually the steel products are delivered by bulk vessel because of the large quantity and the freight. However, there are no bulk vessel enter some seaports so that we have to deliver the cargo by containers. The 6m steel product can be loaded in 20FT container, but the quantity is changed according to the size, usually from 18tons to 25tons.

Images:

- Q: Can a steel square be used for checking the squareness of a router base plate?

- Using a steel square is an effective method for verifying the squareness of a router base plate. This tool is known for its precision and accuracy in measuring and confirming right angles on different objects. To check the squareness of a router base plate, all you need to do is position the steel square against the base plate's edge and observe if it aligns perfectly with the square's sides. Any gaps or misalignments indicate that the base plate is not perfectly square. This technique proves valuable in guaranteeing the precision and accuracy of router cuts, as well as ensuring the proper alignment between the base plate and the router bit.

- Q: Can a steel square be used for checking the flatness of a wall?

- No, a steel square is not suitable for checking the flatness of a wall. It is primarily used for measuring angles and ensuring right angles in carpentry and construction work. For checking the flatness of a wall, a straightedge or a level would be more appropriate.

- Q: How do you use a steel square to determine the angle of a coping cut?

- In order to determine the angle of a coping cut using a steel square, a few simple steps must be followed. Firstly, it is important to ensure that the square is correctly aligned and perpendicular to the material being worked on. This will guarantee precise measurements. Next, position the square against the material's edge, ensuring that one arm of the square is aligned with the material's surface and the other arm is pointing towards the direction of the coping cut. Once the square is in place, observe the scale or measurement markings engraved on the square. Most steel squares have a protractor or angle measuring scale on one arm. This scale will assist in determining the angle of the coping cut. Now, locate the angle reading that aligns with the material's edge. This will indicate the angle at which the coping cut needs to be made. It is important to verify measurements and ensure that the square is securely positioned before making any cuts. It is also recommended to use a pencil or scribe to mark the angle on the material for increased accuracy. Remember that with practice and experience, the ability to accurately determine the angle using a steel square will improve.

- Q: How do you use a steel square to mark out 75-degree angles?

- To use a steel square to mark out 75-degree angles, you would typically align the 45-degree angle of the square with the edge of the material. Then, using a protractor or angle finder, measure 30 degrees from the square's 45-degree angle, which will give you a total of 75 degrees. Finally, draw a line along the edge of the square to mark out the 75-degree angle.

- Q: How do you measure angles with a steel square?

- To measure angles with a steel square, you can align one edge of the square with the reference line and then read the angle measurement directly from the scale provided on the square.

- Q: How do you use a steel square to create dovetail joints?

- To use a steel square to create dovetail joints, first, mark the desired width and length of the tails and pins on the end grain of the wood. Next, position the steel square against the end of the wood and align it with the marked lines. Use a pencil or knife to trace along the edge of the square, creating the tails or pins. Repeat this process on the corresponding piece of wood that will interlock with the first piece. Finally, use a chisel or saw to remove the waste wood between the marked lines, forming the final dovetail joint.

- Q: How do you use a steel square for marking dovetail joints?

- For marking dovetail joints, you'll need to choose the right size steel square. The square consists of a long arm (blade) and a shorter arm (tongue) that form a right angle. To begin, position the blade of the square against the end of the board where the dovetail joint will be. Align the tongue of the square along the edge of the board and make sure it's firmly held against the wood to avoid any inaccuracies. Next, use a sharp pencil or marking knife to mark the desired width of the dovetail on the end grain of the board. The blade of the square will serve as a guide, providing a straight reference line for your markings. To mark the angles of the dovetail, place the square against the marked width line. Align the tongue of the square with the face of the board. Use the edge of the blade as a reference to draw lines that represent the angles of the dovetail. These lines will guide your chisel or saw when cutting the joint. Repeat this process on the mating board, ensuring that the markings align properly with the first board. This will guarantee a precise fit when assembling the dovetail joint. Using a steel square for marking dovetail joints ensures accuracy and consistency in creating well-fitting joints. It helps maintain straight reference lines and ensures the proper marking of dovetail angles, resulting in a strong and visually appealing joint.

- Q: What are the common materials used to make a steel square?

- The common materials used to make a steel square are typically stainless steel, carbon steel, or tool steel. These materials are chosen for their strength, durability, and resistance to corrosion. Stainless steel is often preferred as it offers excellent resistance to rust and staining, making it ideal for outdoor use or in humid environments. Carbon steel is another commonly used material for steel squares due to its affordability and high tensile strength. Tool steel, which is a high-carbon alloy steel, is often used in specialized squares designed for precision measurements and heavy-duty applications. Overall, the choice of material depends on the intended use and the specific requirements of the steel square.

- Q: How does a steel square assist in determining the correct angle for a cove cut?

- When trying to achieve a cove cut, it is crucial to have the appropriate angle for the desired shape and fit. This is where a steel square comes in handy. Serving as a precise and accurate measurement tool, a steel square aids in determining the correct angle. Typically featuring a 90-degree angle, the steel square acts as a reference point. By aligning it with the material's edge that needs to be cut, you can establish a perpendicular line. This perpendicular line is then used to ascertain the correct angle for the cove cut. To find the correct angle, measure the distance from the perpendicular line to the desired endpoint of the cove cut. This measurement will provide the angle necessary to achieve the desired shape and fit. Furthermore, a steel square often includes other angle markings like 45 degrees. These markings can be utilized to create various types of cove cuts or to verify the accuracy of the measurement. Overall, a steel square is a reliable and precise measurement reference that assists in determining the correct angle for a cove cut. By ensuring accuracy and quality, it guarantees the desired outcome of the cut.

- Q: How do you store a steel square to prevent rusting?

- To store a steel square and prevent it from rusting, you should follow a few simple steps: 1. Clean the steel square: Use a damp cloth or sponge to clean any dirt, debris, or grease from the steel square. Make sure to remove any moisture afterwards with a dry cloth to prevent water from causing rust. 2. Apply a protective coating: To provide an extra layer of protection against rust, you can apply a thin coat of oil or a rust-preventive spray. This helps to create a barrier between the steel and the air, preventing oxidation and rust formation. 3. Store in a dry location: Find a cool, dry place to store the steel square. Avoid areas with high humidity or moisture, such as basements or bathrooms. Moisture in the air can accelerate rusting, so it is essential to keep the storage environment dry. 4. Use a desiccant or moisture absorber: If you live in a particularly humid area or have concerns about moisture buildup, you can place a desiccant packet or a moisture absorber near the steel square. These products help to absorb any excess moisture in the air, reducing the risk of rust formation. 5. Avoid contact with other metals: When storing your steel square, make sure it does not come into contact with other metals, especially those prone to rusting. Different metals can create a galvanic reaction, accelerating rust formation. To prevent this, you can wrap the steel square in a soft cloth or store it in a protective case. By following these steps, you can effectively store a steel square and minimize the chances of rusting. Regularly inspect the square for any signs of rust or damage and reapply a protective coating if necessary.

Send your message to us

Hot Rolled Low Carbon Steel Square Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords