Hot Rolled Steel Square Bars Q235,A36,S235JR, SS400

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Steel Square Bars Q235,A36,S235JR, SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Product Advantages:

Hot Rolled Steel Square Bars Q235,A36,S235JR, SS400 are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Standard: GB,

-Grade: Q235 or equivalent.

Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures of Hot Rolled Square Bar:

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

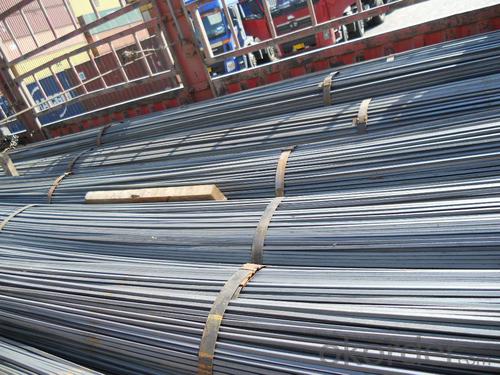

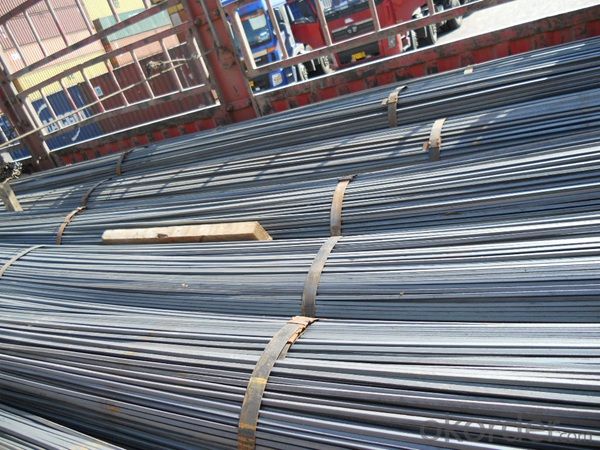

Images:

- Q: Can a steel square be used for flooring installation?

- Yes, a steel square can be used for flooring installation. A steel square, also known as a framing square or carpenter's square, is a versatile tool commonly used in construction and carpentry. While it is primarily used for measuring and marking right angles, it can also be used for various tasks during flooring installation. One of the main uses of a steel square in flooring installation is to ensure the accuracy of cuts and angles. It can be used to mark straight lines and guide the cutting of flooring materials such as tiles, laminate, or vinyl. The square's straight edge can be placed against the material and used as a guide for precise cuts. Additionally, a steel square can help in laying out the flooring pattern. It can be used to measure and mark the layout lines for tiles or planks, ensuring a symmetrical and well-aligned installation. The square's right-angle feature allows for precise measurements and markings, which are crucial for achieving a professional and visually appealing flooring finish. Furthermore, a steel square can be beneficial in checking the squareness of a room or area before starting the installation. By placing the square's corner against the walls or existing flooring, any discrepancies in the angles can be easily identified. This is important as it helps to ensure that the flooring installation starts on a level and square foundation. In conclusion, a steel square can indeed be used for flooring installation. Its versatility, accuracy, and ability to measure and mark right angles make it a valuable tool for various tasks during the flooring installation process.

- Q: How do you use a steel square to lay out a dovetail joint?

- To use a steel square to lay out a dovetail joint, you will need the following tools: a steel square, a pencil or marking knife, and a dovetail template or a set of dovetail angle guides. First, ensure that your steel square is clean and free from any dirt or debris that could affect your measurements. Then, position the steel square against the edge of the workpiece that will form one side of the dovetail joint. The inside edge of the square's blade should be flush with the edge of the workpiece. Next, use a pencil or marking knife to mark the desired width of the dovetail pins or tails on the end grain of the workpiece. You can determine the width based on the size of your stock and personal preference. Typically, a 1:8 or 1:6 angle is used for dovetail joints, but this can vary depending on the project. After marking the width, use the steel square to mark the desired angle of the dovetail joint on the face of the workpiece. Place the square's blade against the face of the workpiece, aligning it with the mark you made for the width of the dovetail, and draw a line along the blade to mark the angle. Repeat these steps for the other side of the dovetail joint, making sure to position the steel square accurately and consistently. This will help ensure that both sides of the joint are properly aligned and will fit together seamlessly. If you have a dovetail template or angle guides, you can use them to guide the steel square and simplify the process. Simply position the template or angle guide against the edge of the workpiece and use the steel square to mark the width and angle accordingly. Remember to always double-check your measurements and marks before cutting the dovetail joint. Accuracy is crucial for a tight and strong joint.

- Q: How do you use a steel square to find angles for compound bevel mitered corners?

- To use a steel square to find angles for compound bevel mitered corners, you would start by measuring and marking the length of each side of the corner on the respective pieces of material. Then, place the steel square against one of the pieces with the 90-degree angle aligned with the edge. Next, adjust the square to align with the other piece by rotating it until the desired angle is achieved. Finally, mark the angle on both pieces using the square as a guide, and cut accordingly.

- Q: How do you use a steel square to determine the angle of a valley rafter cut?

- To use a steel square to determine the angle of a valley rafter cut, you can follow these steps: 1. Place the steel square on the edge of the valley rafter, with one leg of the square aligned with the top edge of the rafter and the other leg extending towards the bottom edge. 2. Slide the square along the rafter until the bottom leg intersects with the roof surface where the valley rafter will be attached. 3. Once the square is properly positioned, mark the angle indicated by the intersection of the square's legs on the rafter. 4. Use a protractor or the angle measuring feature on the steel square to measure the marked angle accurately. 5. Transfer the measured angle onto the valley rafter by aligning the square's legs with the top and bottom edges of the rafter and marking the angle accordingly. 6. Finally, use a saw or other appropriate tools to cut along the marked angle on the valley rafter to achieve the desired cut. Using a steel square in this manner allows you to determine and transfer the correct angle for cutting the valley rafter, ensuring a precise fit and appropriate joint when installing it in the roof structure.

- Q: How do you use a steel square to find angles for compound bevel coping cuts?

- To find angles for compound bevel coping cuts using a steel square, the following steps should be followed: 1. Gain an understanding of compound bevel coping cuts, which are commonly used to fit two intersecting pieces of wood or other materials together. These cuts involve two angles: the miter angle, which determines the horizontal cut, and the bevel angle, which determines the vertical cut. 2. Begin by measuring the miter cut angle. Position the steel square against the material you wish to cut, aligning the long edge of the square with the material's edge. Adjust the square until the inside corner matches perfectly with the edge of the material. Read the angle measurement on the square's scale, typically marked in degrees. 3. Once the miter angle is determined, proceed to find the bevel angle. Place the steel square against the material's edge, aligning the long edge of the square with the edge. Adjust the square until the inside corner aligns perfectly with the material's edge. Read the angle measurement on the square's scale. 4. With the miter angle and bevel angle established, these measurements can be used to set up a compound miter saw or another cutting tool for making the compound bevel coping cuts. Consult the user manual or instructions for your specific tool to learn how to adjust the angles accordingly. 5. After configuring the cutting tool with the correct miter and bevel angles, carefully position the material and make the cuts accordingly. Take your time and ensure accurate adherence to the measurements and angles determined with the steel square. Remember that practice and precision play vital roles in achieving precise compound bevel coping cuts. It may require some trial and error to attain the perfect fit between the coped piece and the other material, so exercise patience and make necessary adjustments.

- Q: TIG welding of stainless steel plate and steel, how to regulate the argon arc welding

- Argon arc welding is a kind of welding technology using argon gas as protective gas. Also called argon gas shielded welding. That is, argon shielded gas is applied around the arc welding, and the air is separated from the welding zone to prevent the oxidation of the welding zone. Argon arc welding technology is based on the principle of arc welding on using argon protection for metal welding, the welding material in high current to be welded on the substrate is melted into liquid form of molten pool, the metal to be welded and welding welding technology to achieve a metallurgical combination, due to the high temperature melting on argon welding continuous feeding in the welding material can not contact with oxygen in the air, thereby preventing the material oxidation, therefore can welding stainless steel, iron metal hardware.

- Q: How do you use a steel square for creating accurate bevel cuts?

- To use a steel square for creating accurate bevel cuts, you need to follow a few steps. First, ensure that your steel square is clean and free from any dirt or debris that could affect its accuracy. Next, determine the desired angle for your bevel cut. This can be done by either using a protractor or by referring to a bevel angle guide or template. Once you have the angle, place your steel square on the material you want to cut, aligning one edge of the square with the edge of the material. Then, using a pencil or a scribe, mark a line along the edge of the steel square. This line will indicate the path of your bevel cut. After marking the line, carefully position your saw blade at the starting point of the line, ensuring that it aligns with the marked path. Hold the steel square firmly against the material, using it as a guide, and begin making the bevel cut along the marked line. Keep a steady hand and maintain constant pressure against the steel square throughout the cut to ensure accuracy. Once you have completed the cut, double-check the angle using a measuring tool to ensure it matches your desired bevel angle. By following these steps and using a steel square as a guide, you can achieve accurate bevel cuts with precision and confidence.

- Q: Can a steel square be used as a makeshift protractor?

- Using a steel square as a makeshift protractor is not possible. Despite their shared purpose of measuring angles, these tools have distinct functions and designs. A steel square is primarily employed for creating right angles and gauging straight edges, whereas a protractor is exclusively crafted for measuring angles of any magnitude. The markings and scale on a steel square lack precision when measuring non-right angles. Opting for the appropriate tools is always the best approach in achieving accurate measurements.

- Q: Can a steel square be used for chair rail installation?

- Yes, a steel square can be used for chair rail installation.

- Q: How do you use a steel square to measure and mark out mitered joints?

- To use a steel square for measuring and marking out mitered joints, you can follow these steps: 1. Start by ensuring that the edges of the steel square are clean and straight. 2. Place the steel square on the workpiece, aligning one edge of the square with the end of the first piece that will form the mitered joint. 3. With a pencil or marking knife, trace along the inside edge of the other side of the square, marking the desired angle for the mitered joint. 4. Repeat the same process on the other end of the workpiece to mark the corresponding angle. 5. Once both angles are marked, use a miter saw or a coping saw to cut along the marked lines, ensuring accuracy. 6. After cutting, fit the two pieces together to check the accuracy of the mitered joint. 7. Adjust as needed and make any necessary modifications until the joint fits tightly and accurately. 8. Finally, secure the mitered joint with appropriate fasteners, such as screws, nails, or dowels, depending on the project requirements. Remember to practice caution when using cutting tools and always wear appropriate safety gear to prevent accidents.

Send your message to us

Hot Rolled Steel Square Bars Q235,A36,S235JR, SS400

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords