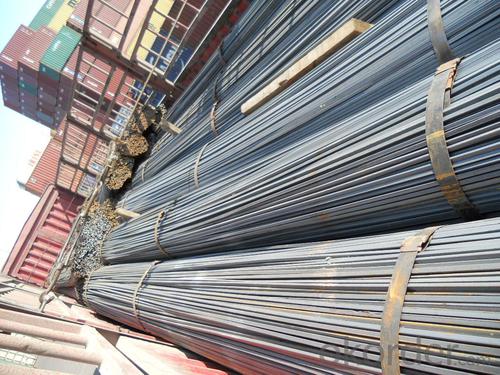

Hot Rolled Square Steel Bars with Cr A36, Q235, SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled Square Steel Bars with Cr A36, Q235, SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Product Advantages:

Hot Rolled Square Steel Bars with Cr A36, Q235, SS400 are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Standard: GB,

-Grade: Q235 or equivalent.

Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures of Hot Rolled Square Steel Bars with Cr A36, Q235, SS400:

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

- Q: Can a steel square be used for checking the squareness of a floor tile?

- No, a steel square cannot be used for checking the squareness of a floor tile. A steel square is primarily used in woodworking and carpentry for measuring and marking angles, not for assessing the squareness of tiles.

- Q: How does a steel square assist in laying out stairs?

- A steel square is a versatile tool that can be invaluable in laying out stairs. It is specifically designed to help with accurate measurements and angles, making it an essential tool for carpenters and builders. When it comes to laying out stairs, a steel square can assist in several ways: 1. Determining the rise and run: The steel square has a tongue and a body, which can be used to find the rise and run of each step. By aligning the square with the edge of the stringer (the inclined board that supports the steps), it can be used to mark the height (rise) and depth (run) of each step accurately. 2. Setting the angle: Stairs need to be built at a specific angle to ensure safety and comfort. The steel square has an adjustable angle feature that allows builders to set the desired slope for the stairs. By adjusting the square to the required angle, builders can easily mark and cut the stringers accordingly. 3. Checking for squareness: It is crucial for stairs to be square, meaning the corners and angles need to be precisely 90 degrees. The steel square can be used to check the squareness of the stringers and ensure that they are properly aligned. This is important to avoid any potential issues with the stability and safety of the staircase. 4. Transferring measurements: The steel square can also be used to transfer measurements accurately. For example, if the width of the stairs needs to be determined, the square can be used to mark the measurement from the stringer onto the tread (the horizontal part of the step). This ensures consistency and accuracy in the layout process. Overall, a steel square is an indispensable tool for laying out stairs. It provides builders with the ability to measure, mark angles, check squareness, and transfer measurements accurately. By utilizing a steel square, carpenters and builders can ensure that the stairs are constructed with precision and in compliance with safety standards.

- Q: How do you use a steel square to measure the height of a workbench?

- To use a steel square to measure the height of a workbench, you can follow these steps: 1. Place the steel square upright on a flat surface, ensuring that it is perpendicular to the ground. The shorter arm of the square should be at the bottom. 2. Position yourself at the side of the workbench where you want to measure the height. 3. Hold the steel square against the side of the workbench, aligning the bottom edge of the shorter arm with the floor or ground. 4. Adjust the square until the longer arm is aligned with the top surface of the workbench. Make sure the square is straight and parallel to the side of the workbench. 5. Once the square is properly aligned, look at the measurement scale on the longer arm. Read the measurement where the top surface of the workbench intersects with the scale. This will give you the height of the workbench. Remember to take accurate measurements and ensure the steel square is properly aligned to get an accurate height measurement for your workbench.

- Q: What is the purpose of the lip on one edge of a steel square?

- The reason for having a lip on one side of a steel square is to offer a designated surface for precise marking and transferring of measurements or angles. When the square is used against a workpiece, the lip serves as a helpful guide, enabling the user to maintain a consistent and accurate line or angle. Additionally, it aids in preventing any slippage or movement of the square while in use, thereby ensuring the accuracy of measurements and layout work. The lip proves to be an invaluable attribute in numerous carpentry, metalworking, and layout endeavors where precise and dependable measurements hold utmost significance.

- Q: How do you use a steel square to ensure the correct angle for a dowel joint?

- To use a steel square for ensuring the correct angle for a dowel joint, you can first mark the desired angle on the square's blade. Then, align the marked angle with the edge of the workpiece and firmly hold the square in place. Finally, use a pencil or marking knife to trace along the edge of the square, transferring the angle onto the workpiece. This ensures accurate and precise dowel joint angles.

- Q: What are some common applications for a steel square in tile installation?

- Tile installation can greatly benefit from the use of a steel square, which is also referred to as a framing square or carpenter's square. This versatile tool can be employed in several ways: 1. Ensuring squareness: The steel square proves invaluable in verifying the squareness of walls and corners. This step is crucial to guarantee the even and aligned placement of tiles. 2. Marking straight lines: By utilizing a steel square, one can effortlessly mark straight lines on both floors and walls. This aids in guiding the installation process, ensuring tiles are positioned uniformly and in an orderly manner. 3. Determining tile layout: With the assistance of a steel square, it becomes a breeze to establish a grid pattern for tiles. This enables accurate determination of tile size and placement, resulting in a harmonious and symmetrical design. 4. Cutting tiles: The steel square serves as a reliable guide when cutting tiles, ensuring precise and straight cuts. By aligning the square with the marked line on the tile, one can score and cut along the edge, achieving clean and accurate cuts. 5. Creating slopes: In certain scenarios, a steel square can be employed to create slopes for drainage purposes. By angling the square at a specific degree, one can ascertain the necessary slope and mark guidelines for tile installation accordingly. In conclusion, a steel square proves to be an invaluable tool in tile installation. Its ability to ensure accuracy, straight lines, and proper alignment saves time and effort, providing a dependable guide for various tasks involved in tiling projects.

- Q: What are some common techniques for using a steel square in guitar making?

- Using a steel square in guitar making can be very helpful for ensuring accuracy and precision in various aspects of the construction process. Here are some common techniques for using a steel square in guitar making: 1. Checking the squareness of the neck pocket: Before attaching the neck to the guitar body, it is crucial to ensure that the neck pocket is perfectly square. Place the steel square against the sides of the neck pocket and check if it forms a perfect 90-degree angle. This will help ensure proper alignment and a secure fit between the neck and body. 2. Checking the alignment of the fretboard: The steel square can be used to check the alignment of the fretboard in relation to the guitar body. Place the square against the edge of the fretboard and check if it aligns perfectly parallel to the centerline of the guitar body. This will help ensure proper intonation and playability of the instrument. 3. Setting up the bridge position: The steel square can be used to accurately position the bridge on the guitar body. Measure and mark the desired distance from the nut to the bridge using a ruler or measuring tape. Then, use the square to ensure that the bridge is positioned perpendicular to the centerline of the guitar body, ensuring proper string alignment and intonation. 4. Checking the angle of the headstock: The steel square can be used to check the angle of the headstock in relation to the neck. By placing the square against the back of the neck and extending it towards the headstock, you can check if the headstock angle is consistent and aligned with the neck. This is important for proper string tension and tuning stability. 5. Checking the straightness of the fretboard: A steel square can also be used to check the straightness of the fretboard. Lay the square along the length of the fretboard, and if there are any gaps between the square and the fretboard, it indicates that the fretboard is not perfectly straight. This can help identify any potential issues with the neck relief or fret leveling. Overall, a steel square is a versatile tool that can help ensure accuracy and precision in various stages of guitar making. By using these techniques, you can enhance the quality and playability of the instrument you are building.

- Q: How do you use a steel square to determine the width of a drawer front?

- In order to determine the width of a drawer front using a steel square, several simple steps must be followed. Initially, position the steel square onto the edge of the drawer front, ensuring that one of its arms rests against the front face of the drawer. Subsequently, glide the square along the edge of the drawer front until the other arm of the square reaches the desired width measurement. This can be achieved by aligning the markings on the square with the desired width measurement on the edge of the drawer front. Once the square is properly aligned, proceed to mark the width measurement directly onto the drawer front using a pencil or a scribe. Lastly, employ a straight edge or a saw to cut along the marked line, guaranteeing a straight and accurate cut. This will yield the desired width for your drawer front. By utilizing a steel square in this manner, precise measurements are attainable, ensuring that your drawer front is cut to the accurate width.

- Q: Can a steel square be used for checking the levelness of a floor?

- No, a steel square cannot be used for checking the levelness of a floor. A steel square is primarily used in carpentry and woodworking for measuring and marking right angles. It is not designed or calibrated to assess the horizontal surface of a floor. To check the levelness of a floor, a more appropriate tool would be a level, such as a spirit level or laser level, which are specifically designed for this purpose. These tools provide accurate readings of the horizontal plane and can help identify any unevenness or slopes in the floor.

- Q: How do you use a steel square for marking stair skirt board angles?

- The process of using a steel square to mark stair skirt board angles is simple. Here is a guide on how to do it: 1. Begin by measuring the rise and run of the stairs. The rise refers to the vertical height between two stair treads, while the run is the horizontal distance between them. Take note of these measurements as they will be important for the next steps. 2. Position the steel square against the skirt board, making sure that the longer arm of the square is vertical and aligned with the edge of the board. 3. Determine the angle for the skirt board by referring to the rise and run measurements. For instance, if the rise is 7 inches and the run is 10 inches, divide the rise by the run (7/10) to obtain the decimal value of 0.7. Locate this decimal value on the rise and run tables of the steel square, which are usually found on the inner part of the square. 4. Once you have found the decimal value on the rise and run tables, locate the corresponding number on the blade of the steel square. This number represents the angle at which you should cut the skirt board. 5. Use a pencil or marking tool to make a mark on the skirt board according to the reference number on the blade of the steel square, indicating the determined angle. 6. Before proceeding with cutting or any subsequent steps, carefully check your measurements and markings to ensure accuracy. By following these steps, you can effectively utilize a steel square to mark stair skirt board angles. It is crucial to measure accurately and double-check your calculations to achieve precise and accurate results.

Send your message to us

Hot Rolled Square Steel Bars with Cr A36, Q235, SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords