Hot-rolled Square Steel Bar With Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Square Steel Bar:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q235 or equivalent.

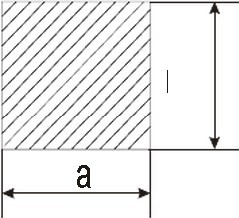

(The section of Square Steel)

Some details of Square Steel Bar:

-List 1. Chemical Composition.

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

-List 2. Physical Properties

Grade | Q235B | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | 235 | 225 | 215 | 205 | |

Tensile Strength | 375~500 | ||||

Elongation δ5% | 26 | 25 | 24 | 23 | |

-List 3.The length of a side and the theoretical weight of Square Steel.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 70 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 4. The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Square Steel Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Raw material for square tubes.

Packaging & Delivery of Square Steel Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of Square Steel Bar:

-Products details(Tag Marks):

-Square Steel Bar during the transportation:

- Q: How do you use a steel square for leveling tasks?

- A steel square, also known as a framing square, is a versatile tool that can be used for various leveling tasks. Here's how you can use a steel square for leveling: 1. Determine the area you want to level: Before using a steel square, identify the specific area or surface that needs leveling. This could be a floor, a countertop, a shelf, or any other flat surface. 2. Clean the surface: Make sure the surface is clean and free from any debris or obstructions. This will ensure accurate leveling results. 3. Place the steel square on the surface: Position the steel square on the surface, making sure it covers the area that needs leveling. The long side of the square should be aligned with the direction you want to level. 4. Check for level: Using a bubble level or a level app on your smartphone, place it on top of the steel square. Adjust the surface until the bubble is centered, indicating that it is perfectly level. 5. Repeat if necessary: If the surface is not level, adjust accordingly. You can use shims or spacers to raise or lower specific areas until the bubble is centered. 6. Double-check: After making adjustments, recheck the level to ensure that it is accurate. Repeat the process until the surface is completely level. Keep in mind that a steel square is a useful tool for checking and leveling surfaces, but it may not be suitable for all situations. For larger areas or more complex leveling tasks, you may need additional tools or equipment.

- Q: Can a steel square be used for checking the squareness of a window frame?

- Yes, a steel square can be used for checking the squareness of a window frame.

- Q: Can a steel square be used for layout work?

- Yes, a steel square can be used for layout work. Steel squares, also known as combination squares, are versatile tools that are commonly used in woodworking and metalworking for laying out and measuring angles, checking for squareness, and marking straight lines. They typically have a 90-degree angle along one edge and a sliding or adjustable head that can be set at different angles to accurately measure and mark angles other than 90 degrees. The steel construction of the square ensures durability and accuracy, making it a reliable tool for layout work.

- Q: How does a steel square assist in determining the correct angle for a sliding dovetail joint?

- The correct angle for a sliding dovetail joint can be determined with the help of a steel square, which serves as a reliable and accurate measurement tool. To ensure a tight and secure fit between the two mating pieces, precise angles are essential for this type of joint. To establish a right angle or 90-degree angle, one can position the steel square against the board or workpiece. This step is crucial, as a sliding dovetail joint typically requires a 90-degree angle to achieve a strong and seamless connection. The steel square can also assist in marking the layout lines on the workpiece. By aligning the square with the edge and drawing a line along its edge, one can ensure consistency and accuracy in the angle throughout the joint. Moreover, the steel square proves useful in checking the angle of the dovetail joint while cutting. By placing the square against the joint, it verifies the correctness of the angle and ensures precise cutting. In conclusion, a steel square is an invaluable tool in determining the correct angle for a sliding dovetail joint. Its accuracy and precision greatly contribute to the joint-making process.

- Q: Can a steel square be used for checking the alignment of wall frames?

- Yes, a steel square can be used for checking the alignment of wall frames. A steel square, also known as a framing square or a carpenter's square, is a versatile tool commonly used in construction and woodworking. It consists of a long arm and a shorter arm that meet at a right angle, forming an "L" shape. When checking the alignment of wall frames, a steel square can be used to ensure that the corners are perfectly square. By placing the shorter arm against one side of the frame and the longer arm against the adjacent side, you can verify if the angle is 90 degrees or if any adjustments need to be made. Additionally, a steel square can be used to measure and mark straight lines, check for straightness, and determine the levelness of surfaces. It is a reliable and accurate tool that is commonly used by carpenters, builders, and framers for a variety of construction tasks. Overall, a steel square is an essential tool for checking the alignment of wall frames due to its versatility, accuracy, and ability to determine right angles.

- Q: How do you use a steel square to check the flatness of a surface?

- In order to check the flatness of a surface using a steel square, it is important to have a reliable and accurate steel square. This tool consists of a ruler-like blade and a perpendicular handle. Here is a step-by-step guide on how to proceed: 1. Make sure that both the surface you wish to check and the steel square are clean and free from any debris or dirt that could impact the accuracy of the measurement. 2. Position the steel square on the surface you want to check, ensuring that one edge of the square is aligned with the surface. 3. Examine the contact between the blade of the steel square and the surface. If the entire length of the blade is in contact with the surface without any gaps or daylight visible, it indicates that the surface is flat. 4. Move the steel square along different areas of the surface, examining for any inconsistencies. If you notice any gaps or daylight between the blade and the surface, it suggests that the surface is not flat in that specific area. 5. Pay attention to the gaps or daylight that you observe. If the gaps are consistently the same size, it may indicate that the surface has a slight bow or warp. However, if the gaps vary in size, it could suggest a more significant irregularity or unevenness in the surface. 6. Take note of any areas where the surface is not flat. This information can be useful in determining the extent of the flatness issue and planning any necessary corrective measures. Keep in mind that using a steel square is not a foolproof method for measuring flatness, especially for large surfaces. It is more suitable for smaller projects or initial assessments. For more precise measurements, specialized tools such as straight edges or laser levels may be required.

- Q: How do you use a steel square to determine the height of an object?

- To determine the height of an object using a steel square, you can place one edge of the square against the base of the object and extend it vertically until it touches the top. Then, you can measure the distance from the base to the point where the square touches the object, which will give you the height of the object.

- Q: What are some common features of steel squares?

- Some common features of steel squares include: 1. Material: Steel squares are made from high-quality steel, which gives them durability and strength. 2. Shape: Steel squares are typically shaped like a right-angled triangle, with one long side and two shorter sides forming a 90-degree angle. 3. Accuracy: Steel squares are designed to provide accurate measurements and angles. The edges and corners are precisely machined to ensure precise and consistent results. 4. Markings: Steel squares often have markings along the edges, allowing users to measure and mark specific lengths or angles. 5. Graduations: Steel squares may have graduations or scales engraved or printed on the surfaces, enabling users to measure angles or distances more easily. 6. Versatility: Steel squares can be used for a variety of purposes, including measuring, marking, and checking right angles, as well as for determining and transferring angles. 7. Size and weight: Steel squares come in various sizes, typically ranging from small pocket-sized squares to larger squares used for more heavy-duty applications. The weight of a steel square depends on its size and thickness. 8. Corrosion resistance: Steel squares are often treated or coated to enhance their resistance to rust and corrosion, ensuring a longer lifespan. 9. Stability: Steel squares are designed to be stable and rigid, providing a reliable reference for accurate measurements and layout work. 10. Multi-functionality: Some steel squares may feature additional features, such as built-in spirit levels, scribing tools, or adjustable components, making them more versatile and convenient for specific applications.

- Q: Can a steel square be used for checking the squareness of a jigsaw blade?

- It is not possible to use a steel square to check if a jigsaw blade is square. Although a steel square is commonly used for measuring and marking right angles, it is not appropriate for assessing the squareness of a jigsaw blade. To determine the squareness of a jigsaw blade, you would require a specialized tool such as a combination square or a collection of precision measuring tools specifically designed for this purpose. These tools generally offer more accurate and precise measurements to evaluate the squareness of a jigsaw blade.

- Q: Can a steel square be used for measuring the height of a flagpole?

- No, a steel square cannot be used for measuring the height of a flagpole. A steel square, also known as a try square, is a tool used primarily for measuring and marking angles of 90 degrees. It is not designed or equipped to measure vertical distances or heights. To measure the height of a flagpole, one would typically use a measuring tape, a laser distance meter, or some other device specifically designed for measuring vertical distances.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Hot-rolled Square Steel Bar With Top Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords