Hot Rolled Steel Square Bar Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

| 1.Specification | ||||||||

| Square bar | Diameter(mm) | Length (mm) | ||||||

| 20~600 | 3000~9000 | |||||||

| Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||

| Max:800 | Max:2200 | Max:9000 | ||||||

| *Specification can be customized for sure. | ||||||||

| 2.Chemical Compositons | ||||||||

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| SCM440 | 0.38~0.45 | 0.17~0.37 | 0.50~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15-0.25 | ≤0.3 |

| 4140 | 0.40~0.45 | 0.15~0.35 | 0.75~1.0 | ≤0.035 | ≤0.040 | 0.8~1.1 | 0.15-0.25 | - |

| SCM415 | 0.38~0.43 | 0.15~0.35 | 0.60~0.9 | ≤0.030 | ≤0.030 | 0.9~1.2 | 0.15-0.30 | ≤0.25 |

| 1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.9 | ≤0.025 | ≤0.035 | 0.9~1.2 | 0.15-0.30 | |

| 3.Delivery Conditions | ||||||||

| Hot rolled +Rough machined (black surface after Q/T)+ Turned (optional) | ||||||||

| 4.Typical Applications | ||||||||

| a.Statically and dynamically stressed components for vehicles | ||||||||

| b.Parts of larger cross-sections, crankshafts, gears | ||||||||

| c.Gears, stem assemblies, | ||||||||

| d.Pump shafts and tool holders | ||||||||

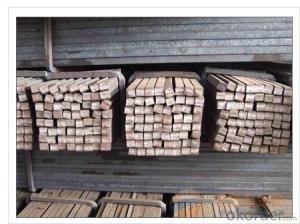

Product Image:

FAQ

Q: Can I get sample and how long will it take?

A:Yes. We can supply sample. And you need to pay for courier.

Q: What's the MOQ?

A: Our MOQ is 1000mt.

Q: What's the delivery time?

A: It will take about 30-45 days after TT or L/C.

Q: What is the payment terms?

A: T/T, L/C at sight

Q: How does your factory carry out quality control?

A: We attach great importance to quality control.Every part of our products has its own QC.

Q: What certificate do you have?

A: We have SGS, ISO9001 etc. Also we can apply any certificate if you need if the qty is OK.

- Q: How do steel products contribute to the hospitality and tourism industry?

- Steel products contribute to the hospitality and tourism industry in various ways. Firstly, steel is an essential material for constructing hotels, resorts, and other hospitality establishments. Its strength, durability, and versatility make it ideal for creating sturdy and aesthetically pleasing structures that can withstand the demands of the industry. From the framing of the building to the interior fixtures and fittings, steel is used extensively, ensuring the safety and comfort of guests. Moreover, steel is used in the manufacturing of furniture, appliances, and amenities found in hotels and resorts. From beds, chairs, and tables to kitchen equipment, steel provides a reliable and long-lasting solution. Its corrosion resistance and easy maintenance make it an excellent choice for furnishings and equipment that can withstand the high usage and frequent cleaning requirements of the hospitality industry. Additionally, steel is crucial for the development of tourist attractions and infrastructure. From iconic landmarks and observation decks to bridges, railways, and transportation systems, steel plays a significant role in creating and maintaining tourist destinations. Its structural capabilities enable the construction of impressive architectural wonders and transportation networks that enhance the accessibility and appeal of tourism sites. In summary, steel products contribute significantly to the hospitality and tourism industry by providing durable and aesthetically pleasing infrastructure, reliable furnishings and equipment, and enabling the development of tourist attractions. Its strength, versatility, and low maintenance requirements make it an essential material that supports the growth and success of the industry.

- Q: What are the different grades and specifications of steel products?

- There are various grades and specifications of steel products available in the market. Some common grades include carbon steel, alloy steel, stainless steel, and tool steel. These grades have different compositions and properties to suit specific applications. Additionally, steel products come in different specifications such as size, shape, surface finish, and tolerance levels, which are determined by industry standards or customer requirements.

- Q: How is steel used in the construction of railway bridges?

- Steel is commonly used in the construction of railway bridges due to its high strength and durability. It is used to create the structural framework and support systems of the bridge, including the main beams, columns, and trusses. Steel's ability to withstand heavy loads and resist deformation makes it ideal for withstanding the weight of trains and ensuring the bridge remains stable and safe. Additionally, steel is easily fabricated, allowing for efficient construction and maintenance of railway bridges.

- Q: What are the different types of steel bridges and structures available?

- There are several types of steel bridges and structures available, including truss bridges, arch bridges, suspension bridges, cable-stayed bridges, and girder bridges. Each type has its own unique design and construction method, suited for specific span lengths and load requirements.

- Q: What are the properties of galvanized steel for outdoor applications?

- Galvanized steel is highly suitable for outdoor applications due to its exceptional properties. It possesses a protective zinc coating that prevents corrosion and rusting, ensuring durability and longevity even in harsh weather conditions. Additionally, galvanized steel exhibits excellent resistance against damage from UV rays, moisture, and various environmental factors, making it ideal for outdoor structures, fences, roofing, and other applications requiring reliable and long-lasting performance.

- Q: How are steel products used in the construction of schools and educational institutions?

- Steel products are widely used in the construction of schools and educational institutions for various purposes. They are commonly used in the structural framework of the buildings, providing strength, durability, and stability. Steel beams, columns, and trusses are used to support the weight of the structure and ensure safety. Additionally, steel is used for roofing systems, walls, and partitions, offering fire resistance and protection against extreme weather conditions. Steel also finds application in the construction of doors, windows, and staircases, providing security and ease of access. Overall, steel products play a crucial role in constructing schools and educational institutions, ensuring a safe and conducive learning environment.

- Q: What are the different grades of steel and their applications?

- There are several grades of steel, each with its own unique properties and applications. Some common grades include mild steel, which is a versatile and widely used grade for general construction and fabrication purposes; stainless steel, known for its corrosion resistance and used in kitchen appliances, medical equipment, and chemical processing; high carbon steel, used for making cutting tools and machinery parts that require high strength; and alloy steel, which contains various elements to enhance its strength, durability, and heat resistance, commonly used in automotive and aerospace industries. These are just a few examples, and there are many more grades of steel available, each tailored for specific applications based on their composition and properties.

- Q: What are the different types of steel bolts and their uses in the construction of power plants?

- There are several types of steel bolts commonly used in the construction of power plants. The most common ones include structural bolts, anchor bolts, and flange bolts. Structural bolts are used to connect heavy structural members, such as steel beams and columns, to provide stability and support. These bolts are typically high-strength and have a larger diameter to withstand heavy loads and vibrations. Anchor bolts are used to secure equipment and machinery to the concrete foundation in power plants. They are designed to provide stability and prevent movement or shifting of the equipment during operation. Anchor bolts are often embedded in the foundation and have threaded ends to attach nuts and washers. Flange bolts are used to connect piping systems, valves, and flanges in power plants. They have a washer-like flange under the head, which distributes the load and prevents leakage. Flange bolts are available in various grades and sizes, depending on the specific requirements of the application. In summary, the different types of steel bolts used in the construction of power plants serve distinct purposes. Structural bolts provide stability to heavy structural members, anchor bolts secure equipment to the foundation, and flange bolts connect piping systems and prevent leakage.

- Q: What are the different types of steel fasteners and their uses in machinery?

- There are various types of steel fasteners commonly used in machinery, including bolts, screws, nuts, and washers. Bolts are used to join two or more components together, providing strong and reliable connections. Screws, on the other hand, are primarily used to hold components in place or to fasten objects to surfaces. Nuts are paired with bolts to secure them tightly, while washers are used to distribute the load and prevent damage to the connected surfaces. These steel fasteners play a crucial role in ensuring the structural integrity and functionality of machinery.

- Q: What are the applications of alloy steel in the energy sector?

- Alloy steel finds numerous applications in the energy sector due to its exceptional strength, corrosion resistance, and heat resistance properties. It is commonly used in the construction of power plants, oil and gas pipelines, and offshore platforms. Alloy steel is also utilized in the manufacturing of turbine blades, reactor vessels, and other critical components in nuclear power plants. Its high temperature and pressure resistance make it suitable for steam boilers and pressure vessels. Additionally, alloy steel is used in the production of high-strength bolts and fasteners, ensuring the structural integrity and safety of energy infrastructure.

Send your message to us

Hot Rolled Steel Square Bar Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords