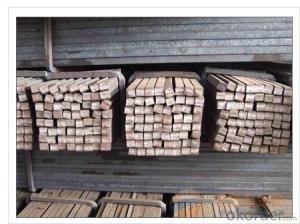

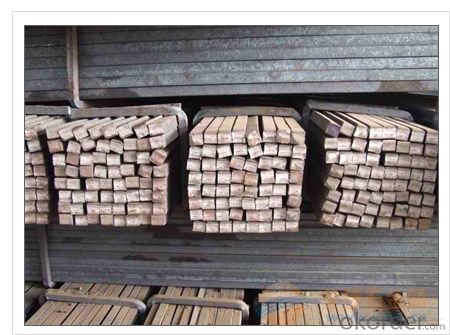

Hot rolled steel flat bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot rolled steel flat bar for construction made in China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot rolled steel flat bar for construction made in China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot rolled steel flat bar for construction made in China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Standard: GB,

-Grade: Q195 or equivalent.

-Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

Measures of HR Square Bar (small measures):

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

7 | 0.385 | 22 | 3.80 |

8 | 0.502 | 24 | 4.52 |

9 | 0.636 | 25 | 4.91 |

10 | 0.785 | 26 | 5.30 |

11 | 0.950 | 28 | 6.15 |

12 | 1.13 | 30 | 7.06 |

13 | 1.33 | 32 | 8.04 |

14 | 1.54 | 34 | 9.07 |

15 | 1.77 | 36 | 10.17 |

16 | 2.01 | 38 | 11.24 |

17 | 2.27 | 40 | 12.56 |

18 | 2.54 | 42 | 13.85 |

19 | 2.82 | 45 | 15.90 |

20 | 3.14 | 48 | 18.09 |

21 | 3.46 | 50 | 19.63 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: (length of a side)2 * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

Usage/Applications of HR Square Bar:

-The Square Bar is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of HR Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks: We make tag marks and color marks. The tag marks with white background and red company logo will be tied up to each bundle of the products. The information is usually including basic information of products and company and other information requested by customers. As for color marks, we will paint both ends of bundles to make sure that it will be more convenient for customers to distinguish them from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products are usually transported to the nearest port from the production place.

FAQ:

Q1: How do we guarantee the quality of our products?

A1: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Can a steel square be used for fence post installation?

- Yes, a steel square can be used for fence post installation. Steel squares are versatile tools that can be used for a variety of tasks, including measuring and marking angles, checking for squareness, and ensuring accurate and plumb installations. When used for fence post installation, a steel square can help ensure that the posts are set at right angles to the ground and are properly aligned. It can be used to measure and mark the correct depth for the post holes, as well as to check that the posts are plumb before and after pouring concrete or backfilling the holes. Overall, a steel square can be a valuable tool to help achieve a straight, level, and secure fence installation.

- Q: How do you use a steel square for marking roof valley rafter angles?

- In order to accurately mark the angles of roof valley rafters, it is important to have a good understanding of the steel square's basic functions and markings. The steel square is comprised of two arms: a longer one known as the blade and a shorter one called the tongue. Typically, the blade measures 24 inches in length, while the tongue is usually 16 inches long. Begin by placing the steel square on the roof rafters, ensuring that the blade is aligned with the ridge line of the roof. The tongue should extend towards the valley of the roof. This positioning allows for precise marking of the angles of the roof valley rafters. To mark the angle, ensure that the square is level and align the tongue with the rafter you wish to measure. Then, use a pencil or marker to make the angle mark on the rafter. Repeat this process for every rafter in the valley. Once all the angles have been marked, you can utilize the steel square to transfer the marks from one rafter to another. Place the tongue of the square on the marked angle of the first rafter and align the blade with the next rafter. Ensure that the square is level, and then use the pencil or marker to transfer the mark to the second rafter. Repeat this step for all the marked angles, maintaining accuracy by properly aligning the square each time. Utilizing a steel square for marking roof valley rafter angles is a straightforward and efficient technique that guarantees consistent and precise cuts during the installation of roof valley rafters. Remember to double-check your measurements and marks before cutting any rafters to ensure accurate and well-fitting angles for a properly constructed roof.

- Q: What are the common applications of a steel square in construction?

- A steel square is commonly used in construction for various applications such as measuring and marking right angles, laying out stair stringers, checking for level and plumb, and determining and transferring angles and slopes. It is a versatile tool that helps ensure accuracy and precision in building and carpentry tasks.

- Q: How do you use a steel square to lay out a hexagon?

- To use a steel square to lay out a hexagon, you would start by aligning the long edge of the square with the edge of your material. Then, using the 90-degree angle of the square, mark two points along the edge of the material. Next, rotate the square 60 degrees and mark two more points, making sure they align with the previous marks. Finally, rotate the square another 60 degrees and mark the remaining two points. Connect all the marked points, and you will have successfully laid out a hexagon using a steel square.

- Q: Are there any limitations to using a steel square?

- The use of a steel square does have its limitations. To begin with, the size and weight of a steel square can pose challenges when handling it, particularly for those with limited strength or dexterity. This can make it tough to use the square for extended periods or for intricate projects that require precise measurements. Additionally, steel squares are primarily designed for right angles and straight measurements, which means they may not be suitable for projects involving angles other than 90 degrees. In such cases, achieving accurate angles may require the use of additional tools or techniques. Furthermore, if not properly maintained, steel squares can be susceptible to rust and corrosion. This can affect their accuracy over time, necessitating regular cleaning and maintenance to ensure reliable measurements. Lastly, steel squares may not be appropriate for certain materials or surfaces. For instance, utilizing a steel square on delicate or easily scratched materials like polished wood or glass could potentially cause damage. In such instances, alternative measuring tools or protective measures may need to be employed. Despite these limitations, steel squares continue to be widely used and valued for their strength, durability, and accuracy in numerous woodworking, metalworking, and construction projects. However, it is crucial to be aware of their limitations and adapt accordingly when necessary.

- Q: What are the different angles that can be measured with a steel square?

- A steel square can be used to measure various angles, including right angles (90 degrees), acute angles (less than 90 degrees), obtuse angles (greater than 90 degrees but less than 180 degrees), and straight angles (180 degrees).

- Q: Can a steel square be used for checking the flatness of a countertop joint?

- Using a steel square to assess the flatness of a countertop joint is not suitable. The steel square serves as a measuring tool for right angles, mainly employed for marking and confirming squareness. Its purpose does not involve precise measurement of a surface's flatness or levelness. For a more suitable evaluation of a countertop joint's flatness, one should consider employing either a straightedge or a precision level.

- Q: How do you use a steel square to measure and mark 185.625-degree angles?

- In order to measure and mark a 185.625-degree angle using a steel square, a series of steps must be followed. To begin, locate the steel square's 90-degree angle, which is created by the long side (blade) and the short side (tongue). This specific angle is commonly denoted by a right angle symbol (90°). Following that, align the blade of the steel square with one of the sides of the angle that requires measurement. Confirm that the tongue is perpendicular to the blade and extending in the opposite direction. Subsequently, rotate the steel square until the edge of the tongue intersects with the other side of the desired angle. Ensure that the blade remains aligned with the first side. At this stage, the measurement of the desired angle can be observed on the tongue of the steel square. Nevertheless, due to the absence of markings beyond 90 degrees on a steel square, a protractor or another tool with smaller increments may be necessary to determine the precise measurement of 185.625 degrees. Once the correct angle has been determined, a pencil or another marking tool can be used to make the corresponding mark on the workpiece. It is important to exercise caution and maintain stability of the square during the marking process to prevent any inaccuracies.

- Q: Can a steel square be used for plumbing pipe layout?

- Yes, a steel square can be used for plumbing pipe layout. A steel square, also known as a framing square or an engineer's square, is a versatile tool that can be used for various layout and measurement tasks in construction and plumbing. It can help ensure accurate angles and straight lines, making it useful for laying out plumbing pipes in a precise manner.

- Q: How do you use a steel square to lay out a compound miter cut?

- To use a steel square to lay out a compound miter cut, you will need to follow a few steps. First, make sure you have a clear understanding of what a compound miter cut is. It is a cut that involves both an angle and a bevel. This means that the saw blade will need to be tilted and angled simultaneously to achieve the desired cut. Next, gather the necessary tools, including a steel square, a pencil, and a measuring tape. It is also helpful to have a miter saw or a compound miter saw for making the actual cut. Begin by determining the angle at which the cut needs to be made. This can be done by referring to the project plans or by measuring the angle on the workpiece directly. Once you have the angle, loosen the bevel adjustment on your miter saw and set it to the desired angle. Now, take the steel square and align one edge against the face of the workpiece. Make sure it is flush and straight, and then mark the desired cut line on the workpiece using a pencil. To find the bevel angle, position the steel square against the edge of the workpiece, aligning one leg against the face and the other leg against the edge. Again, ensure the square is flush and straight. Then, draw a line along the other leg of the square. The point where the two lines intersect represents the desired cut line for your compound miter cut. Double-check your measurements and angles before proceeding. Finally, carefully adjust the bevel angle on your miter saw to match the line you just drew. Secure the workpiece firmly in place and proceed with making the compound miter cut. Remember to always prioritize safety when using power tools. Wear appropriate protective gear, follow the manufacturer's instructions for your specific saw model, and take necessary precautions to avoid accidents.

Send your message to us

Hot rolled steel flat bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords