Mild stainless steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering mild stainless steel flat bar for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Mild stainless steel flat bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel flat bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

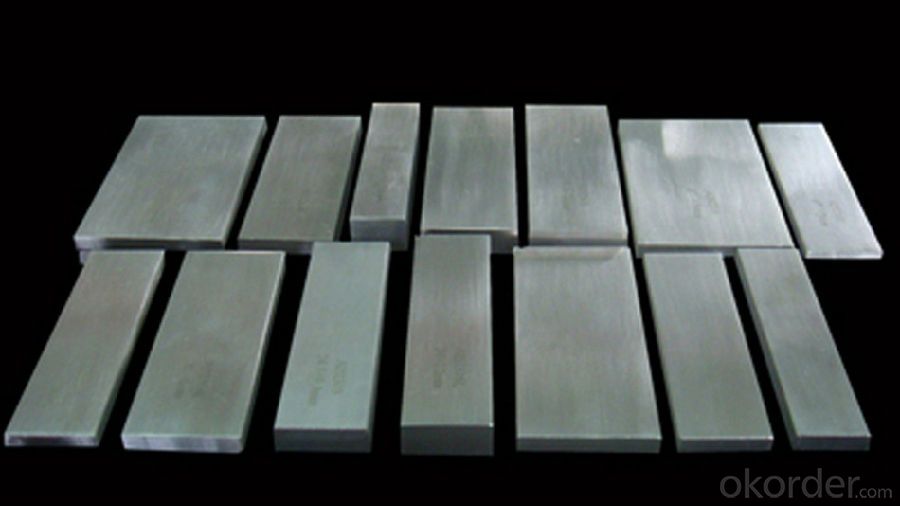

Product Specifications:

Commodity: High Quality Mild Steel Flat Bar

Standard: GB

Material: Q235

Brand name: FLATSPACE

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

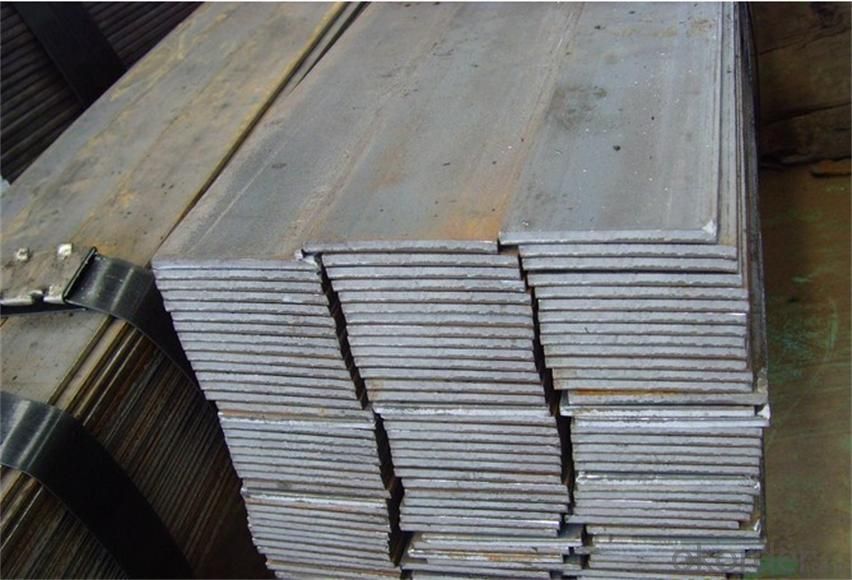

Usage/Applications of High Quality Mild Steel Flat Bar

Widely used for construction, Machinery manufacturing, Iron tower steel structure, Shipbuilding; Steel grating, Staircase, Bridge, Viaduct, Railway spare parts, Boilers making etc.

Production Flow of High Quality Mild Steel Flat Bar

The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

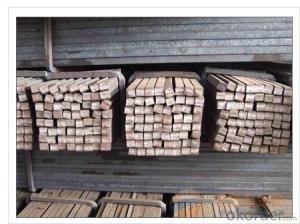

Packaging & Delivery of High Quality Mild Steel Flat Bar

Packaging Details: The Steel Flat Bars are packed in bundles and loaded in 20 feet/40 feet container, or shipped by bulk cargo ,also we can do as customer's requirements.

Delivery Details:30~45 days upon the receipt of buyer payment by T.T. or L/C.

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can steel flat bars be used in construction projects?

- Yes, steel flat bars are commonly used in construction projects due to their durability, strength, and versatility. They are often used for structural support and framing, as well as for various applications such as railing, grating, and reinforcement.

- Q: Friction coefficient of steel pipe and flat steel on roller table!

- Flat, refers to the width 12-300mm, thickness 4-60mm, cross section is rectangular in shape and with a blunt edge of steel. Flat steel can be finished steel, or can be used as the blank of welded pipe and thin slab for laminated sheet rolling. Main application: flat steel is used as a material, used for making iron, tools and machinery parts, and used as frame structures and escalators for buildings.

- Q: How do you prevent pitting or cracking on steel flat bars?

- To prevent pitting or cracking on steel flat bars, there are several measures that can be taken: 1. Proper Storage: Ensure that the steel flat bars are stored in a dry and well-ventilated area to prevent exposure to moisture. Moisture can lead to corrosion and pitting. 2. Protective Coatings: Apply a suitable protective coating on the steel flat bars to create a barrier against moisture and other corrosive elements. Common coatings include paint, varnish, or specialized anti-corrosion coatings. 3. Regular Cleaning: Regularly clean the steel flat bars to remove any dirt, debris, or corrosive substances that might accumulate on the surface. Use mild detergents or specialized cleaning solutions that are safe for steel. 4. Avoiding Impact or Overloading: Handle the steel flat bars with care to prevent any impact or excessive loads that can lead to cracking. Avoid dropping or mishandling the bars during storage, transportation, or installation. 5. Proper Handling and Transportation: When moving or transporting steel flat bars, ensure they are properly secured to prevent any movement or rubbing against each other, which can cause pitting or scratching. 6. Avoid Exposure to Extreme Temperatures: Steel flat bars should be protected from extreme temperatures, especially rapid cooling or heating, as this can cause thermal stress and potential cracking. Allow the bars to gradually acclimate to temperature changes when possible. 7. Regular Maintenance: Inspect the steel flat bars periodically to identify any signs of pitting, cracking, or corrosion. Promptly address any issues by cleaning, repairing, or applying protective coatings as necessary. By implementing these preventive measures, you can minimize the risk of pitting or cracking on steel flat bars, ensuring their longevity and preserving their structural integrity.

- Q: Can steel flat bars be used for creating architectural facades or cladding?

- Yes, steel flat bars can be used for creating architectural facades or cladding. Steel flat bars offer strength, durability, and versatility, making them suitable for various architectural applications. They can be shaped, cut, and joined together to create unique and visually appealing facades or cladding systems. Additionally, steel flat bars can be finished with different coatings or surface treatments to enhance their appearance and protect against corrosion, making them a popular choice for architectural projects.

- Q: Are steel flat bars suitable for load-bearing applications?

- Yes, steel flat bars are suitable for load-bearing applications. They are commonly used in construction and engineering projects where strength and durability are required to support heavy loads. The flat shape of the bar provides stability and resistance to bending or warping under pressure, making it an ideal choice for load-bearing purposes.

- Q: How are steel flat bars different from steel round bars?

- Steel flat bars and steel round bars differ in their shape and physical properties. The most obvious difference is their shape: steel flat bars have a flat surface and rectangular cross-section, while steel round bars have a cylindrical shape. In terms of applications, steel flat bars are commonly used in construction, manufacturing, and industrial projects where a sturdy and durable material is required. They are often used as support or reinforcement structures due to their flat surface, which provides stability and strength. Steel flat bars are also versatile and can be easily welded, cut, and shaped into various forms, making them suitable for a wide range of projects. On the other hand, steel round bars are primarily used in applications that require strength, such as shafts, axles, and structural components. The cylindrical shape of round bars offers excellent strength and load-bearing capacity, making them ideal for applications where torsional forces are involved. Additionally, round bars are commonly used in the manufacturing of machinery, tools, and equipment due to their ability to withstand high stress and pressure. Another difference between steel flat bars and steel round bars lies in their physical properties. Due to their different shapes, flat bars have a larger surface area compared to round bars with the same weight. This characteristic can result in higher heat transfer rates and improved corrosion resistance for steel flat bars. Round bars, on the other hand, have a smaller surface area, which may make them more suitable for certain applications where reduced friction and drag are desired. In summary, steel flat bars and steel round bars differ in their shape, applications, and physical properties. Flat bars are commonly used for support and reinforcement in construction and manufacturing, while round bars are often used for strength and load-bearing applications. Understanding these differences can help in selecting the most appropriate type of steel bar for a given project or application.

- Q: Are steel flat bars suitable for food processing applications?

- Steel flat bars can be suitable for food processing applications depending on the specific requirements and conditions of the application. Steel is a durable and strong material that can withstand high temperatures, pressure, and harsh cleaning agents commonly used in food processing facilities. However, it is important to consider certain factors before using steel flat bars in food processing. One crucial aspect is the type of steel used. Stainless steel, especially those with a high corrosion resistance like 304 or 316 grades, is typically preferred for food processing applications. This is because stainless steel has excellent resistance to corrosion, staining, and bacterial growth, ensuring hygienic conditions. Additionally, the surface finish of the steel flat bars is important. A smooth, polished finish is preferred as it prevents the accumulation of dirt, bacteria, and other contaminants. This aids in maintaining cleanliness and preventing cross-contamination. Furthermore, the steel flat bars should be free from any coatings or finishes that may leach harmful substances into the food during processing. It is essential to ensure that the steel used is compliant with food safety regulations and certifications. In conclusion, steel flat bars can be suitable for food processing applications if they are made from stainless steel with high corrosion resistance, have a smooth surface finish, and comply with food safety regulations. It is always recommended to consult with experts or adhere to industry standards to ensure the suitability of steel flat bars for specific food processing applications.

- Q: Can steel flat bars be used for making brackets or brackets?

- Yes, steel flat bars can definitely be used for making brackets or brackets. Steel is a strong and durable material, making it suitable for various applications, including bracket manufacturing. Steel flat bars can be easily shaped, cut, and welded to create brackets of different sizes and shapes. They provide stability and support, making them ideal for holding objects or providing structural reinforcement. Additionally, steel's corrosion resistance makes it a reliable choice for brackets that may be exposed to moisture or other harsh conditions.

- Q: Are steel flat bars available in non-standard lengths?

- Yes, steel flat bars are available in non-standard lengths.

- Q: What are the different shapes available for steel flat bars?

- Steel flat bars come in various shapes to cater to different needs. The most commonly seen shape is the rectangular flat bar, characterized by its straight, flat surface and sharp edges. This particular shape finds frequent use in structural applications like building frames and supports. Another shape available is the square flat bar, which boasts equal width and thickness on all sides, forming a square shape. This shape is often employed for ornamental purposes, such as decorative trim or fencing. Furthermore, one can also find round-edged flat bars, which feature rounded corners instead of sharp edges. This shape is particularly favored in applications where safety is a concern, as the rounded edges minimize the risk of injury or damage. Moreover, certain manufacturers offer special shapes like tapered flat bars or custom profiles, specifically designed to meet particular requirements or provide unique functionality for specific applications. All in all, the assortment of shapes available for steel flat bars offers a wide range of options to accommodate diverse needs and preferences. This allows for versatility and customization across various industries and projects.

Send your message to us

Mild stainless steel flat bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords