Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Square Steel:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q195 or equivalent.

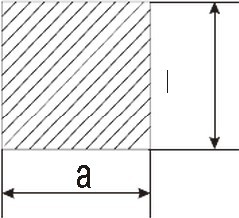

(The section of Square Steel)

Some details of Square Steel:

-List 1.The length of a side and the theoretical weight of Square Bar.

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

6 |

0.283 |

32 |

8.04 |

|

7 |

0.385 |

*33 |

8.55 |

|

8 |

0.502 |

34 |

9.07 |

|

9 |

0.636 |

*35 |

9.62 |

|

10 |

0.785 |

36 |

10.17 |

|

11 |

0.950 |

38 |

11.24 |

|

12 |

1.13 |

40 |

12.56 |

|

13 |

1.33 |

42 |

13.85 |

|

14 |

1.54 |

45 |

15.90 |

|

15 |

1.77 |

48 |

18.09 |

|

16 |

2.01 |

50 |

19.63 |

|

17 |

2.27 |

53 |

22.05 |

|

18 |

2.54 |

*55 |

23.6 |

|

19 |

2.82 |

56 |

24.61 |

|

20 |

3.14 |

*58 |

26.4 |

|

21 |

3.46 |

60 |

28.26 |

|

22 |

3.80 |

63 |

31.16 |

|

*23 |

4.15 |

*65 |

33.17 |

|

24 |

4.52 |

*68 |

36.3 |

|

25 |

4.91 |

70 |

38.49 |

|

26 |

5.30 |

75 |

44.16 |

|

*27 |

5.72 |

80 |

50.24 |

|

28 |

6.15 |

85 |

56.72 |

|

*29 |

6.60 |

90 |

63.59 |

|

30 |

7.06 |

95 |

70.85 |

|

*31 |

7.54 |

100 |

78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 2. The allowed tolerance of Square Steel:

|

Length of a side(mm) |

Allowed Tolerance | ||

|

Group1 |

Group2 |

Group3 | |

|

5.5~7 |

±0.20 |

±0.30 |

±0.40 |

|

7~20 |

±0.25 |

±0.35 |

±0.40 |

|

20~30 |

±0.30 |

±0.40 |

±0.50 |

|

30~50 |

±0.40 |

±0.50 |

±0.60 |

|

60~80 |

±0.60 |

±0.70 |

±0.80 |

|

80~110 |

±0.90 |

±1.0 |

±1.1 |

|

110~150 |

±1.2 |

±1.3 |

±1.1 |

|

150~190 |

―― |

―― |

±2.0 |

|

190~250 |

―― |

―― |

±2.5 |

Chemical Composition:

|

Standard |

Grade |

Element (%) | ||||

|

GB |

Q195 |

C |

Mn |

S |

P |

Si |

|

≤0.12 |

≤0.50 |

≤0.04 |

≤0.035 |

≤0.3 | ||

-Method of deoxidation: F, b, Z

Usage/Applications of Square Steel:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Square Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of Square Steel:

- Q:How do you use a steel square to determine the slope of a garden fence?

- To use a steel square to determine the slope of a garden fence, you would first need to gather a few materials such as a steel square, a level, a tape measure, and perhaps some stakes and string. 1. Begin by measuring the length of the fence line you want to check for slope using a tape measure. This will give you the horizontal distance you will be working with. 2. Choose a section of the fence line where you want to determine the slope. It is recommended to choose a relatively straight and level section for accuracy. 3. Next, place the steel square on the ground at the starting point of the section you chose. Ensure that the square's long side is parallel to the fence line. You can use stakes and string to help keep the square in place if necessary. 4. Use a level to adjust the steel square until it is perfectly level. This is important to ensure accurate measurements. 5. Once the square is level, use the tape measure to measure the vertical distance between the ground and the top edge of the steel square. This measurement will give you the rise of the fence line over the horizontal distance you measured earlier. 6. To determine the slope, divide the rise measurement by the horizontal distance. This will give you the slope ratio, typically expressed as a fraction or percentage. For example, if the rise is 2 feet and the horizontal distance is 10 feet, the slope would be 2/10 or 1/5, which can also be expressed as 20%. By following these steps, you can use a steel square to determine the slope of a garden fence accurately. This information can be helpful in ensuring proper drainage and stability of the fence, as well as for planning and designing other aspects of your garden.

- Q:What are the dimensions of a standard steel square?

- The dimensions of a standard steel square can vary depending on the specific type and purpose of the square. However, a commonly used standard steel square, known as a try square or carpenter's square, typically has a blade length of around 6 to 12 inches (15 to 30 centimeters) and a handle length of around 4 to 6 inches (10 to 15 centimeters). The blade and handle are usually at a right angle to each other, forming a perfect 90-degree angle. This allows for precise measurements and squareness when working on various woodworking or metalworking projects.

- Q:How do you use a steel square to create dovetail joints?

- To use a steel square to create dovetail joints, you will need a few additional tools such as a marking gauge, a chisel, a mallet, and a dovetail saw. 1. Start by marking out the tails on the end grain of the board that you want to create the dovetail joint on. Use the steel square to ensure the lines are at a 90-degree angle to the face of the board. 2. Next, set the marking gauge to the desired width of the tails and use it to scribe lines across the face grain of the board. The steel square can help you ensure the lines are perpendicular to the face. 3. Now, using the dovetail saw, carefully cut along the scribed lines on the face grain. The steel square can be used to guide the saw to maintain a straight and square cut. 4. Once the tails are cut, use the steel square to transfer the shape of the tails onto the board that will receive the dovetail joint. Hold the square against the tails and trace along the edges to mark the corresponding pins. 5. With the pins marked, use the marking gauge to scribe lines across the face grain of the receiving board. Again, make sure the lines are at a 90-degree angle to the face using the steel square. 6. Now, carefully cut along the scribed lines on the receiving board using the dovetail saw. Make sure to cut just outside the lines to leave room for fitting the joint together. 7. After cutting the pins, you can use a chisel and mallet to remove the waste material between the pins. The steel square can help you ensure the chisel is held perpendicular to the face to create clean and accurate cuts. 8. Finally, test fit the joint by assembling the tails into the pins. If any adjustments are needed, use the chisel and mallet to carefully remove excess material until the joint fits tightly and securely. Remember to always work with caution and precision when using any tools, especially sharp ones. Practice on scrap wood before attempting dovetail joints on your actual project to gain confidence and improve your skills.

- Q:Can a steel square be used for checking the squareness of a window frame corner?

- Yes, a steel square can be used to check the squareness of a window frame corner. A steel square is a tool commonly used by carpenters and builders to ensure that corners are perfectly square. It has a 90-degree angle that allows for accurate measurement and checking of right angles. By placing the steel square against the window frame corner, one can easily determine if the corner is perfectly square or if adjustments need to be made. Therefore, a steel square is a reliable tool for checking the squareness of a window frame corner.

- Q:Can a steel square be used for laying out a foundation?

- Laying out a foundation can be achieved by utilizing a steel square. Known as a framing square or carpenter's square, this versatile tool plays a crucial role in carpentry and construction. It serves to measure and mark angles, as well as to assess the accuracy and squareness of lines and corners. To guarantee the squareness of corners and angles during foundation laying, the steel square comes into play. Its application involves measuring and marking the dimensions of the foundation, ensuring precise and accurate placement with the correct shape. The straight edges and right angles of the steel square render it an ideal tool for this specific task. Furthermore, the steel square finds usefulness in the layout of additional foundation elements like anchor bolts or anchor plates. By leveraging the steel square for measuring and marking the positions of these elements, their alignment can be precisely executed, harmonizing with the overall foundation layout. All in all, the steel square holds immense value in the process of foundation laying. Its usage guarantees accuracy, ensuring proper alignment and squareness of the foundation.

- Q:Can a steel square be used for checking the alignment of a fence?

- A fence's alignment can indeed be checked using a steel square. This versatile tool, also referred to as a framing square or carpenter's square, serves multiple purposes in the field of carpentry and construction. It comprises a lengthy blade and a shorter tongue, creating a right angle and featuring measurement markings along both sides. In order to verify the alignment of a fence, a steel square can be utilized to guarantee that the posts and rails are appropriately perpendicular to one another. This is crucial for upholding the fence's structural integrity and stability. To begin, position the steel square against one of the fence posts, ensuring that the blade aligns with the post while the tongue extends along the rail. Verify whether the square is flush against both the post and rail. If it is not, proceed to make adjustments to align them properly. Subsequently, employ a level to determine if the square is truly vertical. If the bubble in the level is centered, it indicates that the fence post is plumb. If it is not centered, make the necessary adjustments to the post until it achieves perfect verticality. Repeat this procedure for each fence post and rail to guarantee that the entire fence maintains proper alignment. Utilizing a steel square can assist you in achieving a fence that is straight and level, thereby enhancing both its functionality and aesthetic appeal.

- Q:How do you use a steel square for marking roof hip angles?

- To use a steel square for marking roof hip angles, you will need to follow a few steps. First, make sure that your steel square is clean and in good condition. To begin, position the square on the edge of the roof hip with one leg of the square aligned with the roof slope. The other leg of the square should be aligned with the ridge of the roof. Next, adjust the square until it is perfectly level and perpendicular to the roof surface. This will ensure accurate measurements and markings. Once the square is properly aligned, you can use a pencil or marker to mark the desired angle on the roof surface. Make sure to mark both sides of the hip for accurate cutting and installation. After marking the angles, you can use a saw or other cutting tool to cut along the marked lines. It is important to note that using a steel square requires precision and accuracy, so take your time and double-check your measurements before making any cuts. Additionally, always prioritize safety by wearing appropriate protective gear and using caution when working at heights.

- Q:How does a steel square assist in determining the correct angle for a beaded joint?

- There are several ways in which a steel square can be utilized to determine the correct angle for a beaded joint. To begin with, the steel square possesses a 90-degree angle that can be employed as a point of reference to ensure that the beaded joint is perfectly perpendicular to the workpiece. By placing the square against the workpiece and aligning it with the joint, one can visually verify whether the joint is at a right angle or necessitates adjustment. Furthermore, the steel square enables the measurement and transfer of angles. Along its edges, the square typically features various degree markings that facilitate precise angle measurements. This proves particularly advantageous when dealing with beaded joints that require specific angles, such as mitered corners or angled cuts. By utilizing the square as a guide, one can accurately mark the desired angle on the workpiece and guarantee a precise beaded joint. Moreover, the steel square can function as a guide during the cutting or shaping of materials for the joint. By aligning the square with the workpiece and marking the desired angle, one can utilize the square as a reference point during the cutting or shaping process. This aids in achieving accurate and consistent angles across multiple pieces, resulting in a well-fitted and aesthetically pleasing beaded joint. In summary, a steel square proves indispensable in determining the correct angle for a beaded joint by virtue of its ability to provide a 90-degree reference, facilitate angle measurements and transfers, and serve as a guide during cutting and shaping operations. Its versatility and precision make it an essential tool for ensuring the accuracy and quality of beaded joints.

- Q:How do you use a steel square to measure and mark 326.25-degree angles?

- To measure and mark 326.25-degree angles using a steel square, the following steps should be followed: 1. Position the steel square on either a level surface or the material where the angle is to be marked. 2. Align the extended side of the square with the reference line or edge that requires measurement. 3. Observe the degree markings on either the elongated side or the inner part of the square. 4. Begin from 0 degrees and progress along the degree markings until reaching 326.25 degrees. Since the markings may be evenly spaced, estimation or interpolation may be necessary to obtain the precise measurement. 5. Once the 326.25-degree marking is identified, employ a pencil or marker to create a small mark on the material being worked on. The square can be used as a guide to ensure the mark is accurate and aligned. 6. If a line needs to be drawn or a longer mark is required, the elongated side of the square can serve as a straightedge to extend the mark in the desired direction. Be mindful to handle the steel square with care and ensure its stability during the process of measuring and marking the angle.

- Q:Can a steel square be used for checking the squareness of a miter saw fence?

- Indeed, the squareness of a miter saw fence can be assessed using a steel square. The steel square, being a versatile tool, proves useful in guaranteeing precise and exact angles in different woodworking scenarios, such as the evaluation of a miter saw fence's squareness. Upon positioning the steel square against the saw fence and aligning it with the blade, it becomes possible to ascertain whether the fence is flawlessly perpendicular to the blade or necessitates adjustments. The steel square's straight edges serve as a dependable point of reference for evaluating the squareness of the miter saw fence, thus ensuring that your cuts will be meticulous and accurate.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords