High Quality Square Steel With Low Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Square Steel:

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q235 or equivalent.

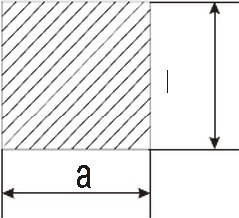

(The section of Square Steel)

Some details of Square Steel:

-List 1. The Chemical Composition.

|

Standard |

Grade |

Element (%) | ||||

|

GB |

Q235B |

C |

Mn |

S |

P |

Si |

|

0.12~0.20 |

0.3~0.7 |

≤0.045 |

≤0.045 |

≤0.3 | ||

-List 2.The length of a side and the theoretical weight of Square Steel.

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

6 |

0.283 |

32 |

8.04 |

|

7 |

0.385 |

*33 |

8.55 |

|

8 |

0.502 |

34 |

9.07 |

|

9 |

0.636 |

*35 |

9.62 |

|

10 |

0.785 |

36 |

10.17 |

|

11 |

0.950 |

38 |

11.24 |

|

12 |

1.13 |

40 |

12.56 |

|

13 |

1.33 |

42 |

13.85 |

|

14 |

1.54 |

45 |

15.90 |

|

15 |

1.77 |

48 |

18.09 |

|

16 |

2.01 |

50 |

19.63 |

|

17 |

2.27 |

53 |

22.05 |

|

18 |

2.54 |

*55 |

23.6 |

|

19 |

2.82 |

56 |

24.61 |

|

20 |

3.14 |

*58 |

26.4 |

|

21 |

3.46 |

60 |

28.26 |

|

22 |

3.80 |

63 |

31.16 |

|

*23 |

4.15 |

*65 |

33.17 |

|

24 |

4.52 |

*68 |

36.3 |

|

25 |

4.91 |

70 |

38.49 |

|

26 |

5.30 |

75 |

44.16 |

|

*27 |

5.72 |

80 |

50.24 |

|

28 |

6.15 |

85 |

56.72 |

|

*29 |

6.60 |

90 |

63.59 |

|

30 |

7.06 |

95 |

70.85 |

|

*31 |

7.54 |

100 |

78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 3. The allowed tolerance of Square Steel:

|

Length of a side(mm) |

Allowed Tolerance | ||

|

Group1 |

Group2 |

Group3 | |

|

5.5~7 |

±0.20 |

±0.30 |

±0.40 |

|

7~20 |

±0.25 |

±0.35 |

±0.40 |

|

20~30 |

±0.30 |

±0.40 |

±0.50 |

|

30~50 |

±0.40 |

±0.50 |

±0.60 |

|

60~80 |

±0.60 |

±0.70 |

±0.80 |

|

80~110 |

±0.90 |

±1.0 |

±1.1 |

|

110~150 |

±1.2 |

±1.3 |

±1.1 |

|

150~190 |

―― |

―― |

±2.0 |

|

190~250 |

―― |

―― |

±2.5 |

Usage/Applications of Square Steel:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for square tubes.

Packaging & Delivery of Square Steel:

-Packing Detail: The products can be packed in bundles by steel wires.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation & Marking:

-Transportation:

1, The products can be delivered by bulk vessel or by container.

2, The maximum quantity of loading of container is 25 tons.

3, The products usually are transported to the nearest port from the production place.

-Marks:

1, Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

2, Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

Photos of Square Steel:

- Q: How do you use a steel square to measure and mark compound angles?

- To use a steel square to measure and mark compound angles, you need to follow these steps: 1. Set the steel square on the workpiece, aligning the long edge with the reference edge or surface. 2. Adjust the square to the desired angle by pivoting it around the reference edge. Ensure that both the blade and tongue of the square are parallel to the corresponding angled surfaces you want to measure or mark. 3. Once the square is set, use a pencil or marking tool to trace along the edges of the blade and tongue, marking the compound angle on the workpiece. 4. If you need to transfer the compound angle to another piece, repeat the above steps using the marked workpiece as the new reference edge. By carefully aligning and adjusting the steel square, you can accurately measure and mark compound angles on various woodworking or metalworking projects.

- Q: Is there a specific method for using a steel square correctly?

- Using a steel square correctly requires a specific method. A steel square, which is also known as a framing square or carpenter's square, is a versatile tool used in woodworking and carpentry for measuring, marking, and guiding straight, square, and angled lines. To ensure proper usage of a steel square, follow these steps: 1. Get acquainted with the different parts: A steel square consists of two arms, a body, and a tongue. The arms typically measure 24 inches in length, while the body and tongue form a right angle. The body is the longer side, while the tongue is the shorter one. 2. Verify accuracy: Prior to using the steel square, it is essential to check if it is correctly calibrated and accurate. Inspect the edges for any damage or wear that may affect its precision. 3. Make straight markings: To mark a straight line, position the body of the square against the material's edge that you are working with. Align the edge of the material with the desired measurement mark on the square's body. Securely hold the square in place and draw a line along the tongue. 4. Make square markings: For marking a square or a 90-degree angle, align the body of the square against one edge of the material. Steadily hold the square in place and draw a line along the tongue. Next, rotate the square 90 degrees and align the body against the adjacent edge. Draw a line along the tongue intersecting the previous line. The point of intersection indicates a perfect square. 5. Measure and mark angles: Steel squares often have degree markings on the body and tongue, enabling you to measure and mark specific angles. Align the square accordingly, using the degree markings as a guide, and mark the desired angle on your material. 6. Check for squareness: A steel square can also be utilized to ascertain if a corner or joint is square. Position the body of the square against one edge of the corner and the tongue against the other. If the square fits perfectly, the corner is square. If there is a gap, the corner is not square and may require adjustment. Remember to use a pencil or a marking tool with a fine point to ensure accurate markings. Additionally, take your time, apply firm but gentle pressure, and double-check your measurements to ensure precision. Practicing and gaining experience will enhance your proficiency in correctly using a steel square.

- Q: How do you use a steel square to determine the slope of a roof?

- To determine the slope of a roof using a steel square, you would place one leg of the square on the roof surface and extend the other leg vertically. Then, using a level, you would ensure the vertical leg is perfectly plumb. Next, you would measure the distance between the horizontal leg of the square and the roof surface at a particular point. This measurement will give you the roof's rise over run ratio or its slope.

- Q: Can a steel square be used for tile backsplash layout?

- Yes, a steel square can be used for tile backsplash layout. A steel square, also known as a carpenter's square or a framing square, is a versatile tool that can be used for many different tasks, including tile layout. It is made of steel and has a right angle shape, with one long arm and one shorter arm. When laying tiles for a backsplash, it is important to ensure that they are aligned properly and evenly. A steel square can be used to create straight lines and right angles, which are essential for a clean and professional-looking tile installation. It can be used to measure and mark the layout, ensuring that the tiles are positioned correctly and evenly spaced. To use a steel square for tile backsplash layout, start by determining the desired layout and design. Use the longer arm of the square to create straight vertical lines along the edges of the backsplash area, and the shorter arm to create horizontal lines. These lines will serve as a guide for placing the tiles. Additionally, a steel square can be used to check the accuracy of the corners and angles of the tiles. Simply place the square against the edges of the tiles to ensure that they are perfectly aligned and form a right angle. Overall, a steel square is a useful tool for tile backsplash layout as it helps to create straight lines, right angles, and ensures a precise and professional finish.

- Q: How do you use a steel square to determine the angle of a roundover cut?

- To determine the angle of a roundover cut using a steel square, the following steps can be followed: 1. Begin by positioning the steel square against the desired edge of the workpiece where the roundover cut will be made. Make sure that the square is perpendicular to the edge. 2. Identify the corner of the square that aligns with the edge of the workpiece. This corner will serve as the reference point for measuring the angle. 3. Place a protractor on top of the steel square, making sure that the center of the protractor aligns with the reference corner. 4. Observe the angle measurement on the protractor where the edge of the workpiece intersects it. This measurement will provide the angle of the roundover cut. 5. Once the angle has been determined, it can be transferred to the woodworking tool you are using, such as a router or table saw, in order to set the appropriate cutting angle. Remember to thoroughly check your measurements and alignment before making any cuts to ensure accuracy. Additionally, exercise caution and adhere to proper safety protocols when working with power tools.

- Q: How do you use a steel square for making accurate miter cuts?

- To use a steel square for making accurate miter cuts, first, place the square against the edge of the material at the desired angle for the miter cut. Ensure that the square is securely held in place. Then, using a pencil or a scribe, mark along the edge of the square to create a guideline for the cut. Finally, carefully cut along the marked line using appropriate tools, such as a miter saw or a handsaw, while maintaining the square against the material to ensure accuracy.

- Q: How do you use a steel square to find the height of a chimney?

- To use a steel square to find the height of a chimney, you will need a few basic tools and a clear understanding of the process. Here are the steps to follow: 1. Gather the necessary tools: You will need a steel square, a measuring tape or ruler, a level, and a ladder or other means to access the chimney. 2. Position yourself at a distance from the chimney where you can clearly see its top edge. Ensure you have a clear line of sight. 3. Hold the steel square in your hand, with one arm of the square pointing upwards and the other arm pointing horizontally. 4. Extend your arm with the horizontal arm of the square until it aligns with the bottom edge of the chimney. Be careful to keep the square level and parallel with the ground. 5. While maintaining the square in position, adjust your position until the top edge of the chimney aligns with the vertical arm of the steel square. 6. Once the chimney's top edge aligns with the vertical arm of the square, take note of the distance between your hand and the bottom edge of the chimney. This distance represents the height of the chimney. 7. Use a measuring tape or ruler to measure the distance between your hand and the bottom edge of the chimney. Make sure to hold the tape or ruler straight and parallel to the ground for accurate measurement. 8. Once you have the measurement, it represents the height of the chimney from your specific vantage point. It's important to note that this method provides an estimate of the chimney's height, assuming the ground is level and your line of sight is accurate. If you require a more precise measurement, it may be necessary to use alternative methods or consult a professional.

- Q: Can a steel square be used for measuring angles in metal fabrication?

- Indeed, angles in metal fabrication can be measured using a steel square. In metal fabrication, steel squares are widely employed for layout and measurement tasks. Possessing a 90-degree angle and multiple markings along the edges, they facilitate precise measurements and angle determination. Although there are more specialized tools like protractors or digital angle finders available for angle measurement, a steel square suffices for most metal fabrication applications, providing reasonably accurate outcomes. To guarantee accurate angle measurements, it is crucial to calibrate the square correctly and employ it accurately.

- Q: How do you use a steel square to determine the slope of a garden bed?

- To use a steel square to determine the slope of a garden bed, you can follow these steps: 1. Start by placing one edge of the steel square against the ground at the lowest point of the garden bed. 2. Ensure that the steel square is level by using a bubble level or by checking that the bubble is centered within the level. 3. Once the steel square is level, hold it steady in that position. 4. Look at the other edge of the square that is extending away from the ground. This edge represents the slope of the garden bed. 5. Observe the markings on the steel square. Most steel squares have measurements and angles marked on them. 6. Read the measurement or angle that corresponds to the line created by the edge of the square. This will give you the slope of the garden bed. 7. You can either note down the measurement or angle for future reference or use it to make necessary adjustments to the garden bed. By using a steel square, you can accurately determine the slope of a garden bed, which is crucial for proper drainage and irrigation.

- Q: How do you care for and maintain a steel square?

- In order to care for and maintain a steel square, it is important to follow several crucial steps. First and foremost, keeping the steel square clean and free from debris or dirt is crucial. After each use, it is recommended to wipe it down with a clean cloth to eliminate any dust or grime. This practice will prevent any accumulation and guarantee that the square remains in good condition. Secondly, protecting the steel square from rust is essential. Steel is prone to rusting, particularly when exposed to moisture or humidity. To prevent this, it is necessary to store the square in a dry and well-ventilated area. If the square does become wet, it should be thoroughly dried before storing it to prevent any lingering moisture on the surface. Moreover, it is advisable to consider applying a thin coat of oil to the steel square. This can be achieved by using a clean cloth and gently rubbing a small amount of oil onto the surface. The oil acts as a protective barrier against moisture and assists in preventing rust. Nevertheless, it is important to wipe off any excess oil to avoid attracting dust or dirt. Furthermore, regularly checking the accuracy of the square is crucial. Over time, the square may become misaligned or lose its accuracy. To ensure its precision, it is recommended to compare the square against a known straight edge or use a squareness tester. If any discrepancies are found, adjustments may be necessary. Most steel squares are equipped with adjustment screws or bolts that can be utilized to correct any misalignment. Lastly, handling the steel square with care is of utmost importance. Avoiding dropping or mishandling it is crucial to prevent any damage. When not in use, it is wise to store it in a protective case or wrap it in a soft cloth to prevent accidental harm. By following these care and maintenance guidelines, you can guarantee that your steel square remains in good condition, accurate, and ready for use whenever necessary.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 15 Million |

| Main Markets | Middle east; Southeast Asia; Africa; East Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 20%-35% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 6,500 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

High Quality Square Steel With Low Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords