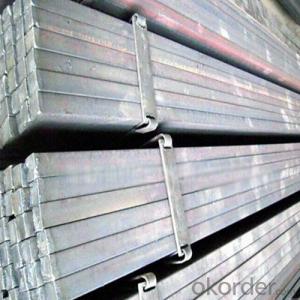

Hot Rolled Carbon Steel Square Bar with Many Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Square Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Product Advantages:

OKorder's Square Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Grade: Q195, Q235, Q345

2. Diameter: 6mm-150mm

3. Length: 6m, 9m, 12m or as customer’s request

4. Tolerance: Within ±5% for weight; ±2mm for diameter

5. Note: The price can be better is the quantity is good

6. Chemical composition

Standard | Grade | Element (%) | ||||

C | Mn | S | P | Si | ||

GB | Q195 | 0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 |

GB | Q235B | 0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 |

-Mechanical Properties:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

53 | 22.05 | 80 | 50.24 |

56 | 24.61 | 85 | 56.72 |

60 | 28.26 | 90 | 63.59 |

63 | 31.16 | 95 | 70.85 |

70 | 38.49 | 100 | 78.50 |

75 | 44.16 |

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: Can stainless steel rust?

A3 Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: Can a steel square be used for checking the squareness of a table saw miter gauge?

- Yes, a steel square can be used for checking the squareness of a table saw miter gauge. A steel square is a precise tool used to measure right angles and can be used to verify if the miter gauge is set at a perfect 90-degree angle. By placing the steel square against the miter gauge and the table saw fence, one can easily determine if the miter gauge is square to the blade. If the square fits perfectly against both the miter gauge and the fence without any gaps or overlaps, then the miter gauge is square. However, it is important to note that while a steel square is a reliable tool for checking squareness, it is always recommended to use a dedicated precision square specifically designed for table saw setups for more accurate results.

- Q: What are some common techniques for using a steel square in masonry?

- There are several common techniques for using a steel square in masonry. One of the most common uses of a steel square in masonry is for measuring right angles. Masons often use the square to ensure that corners are perfectly square when laying bricks or blocks. By placing the square against the corner, they can easily check if it forms a 90-degree angle. This is essential for maintaining the structural integrity and aesthetics of the masonry work. Another technique is to use the steel square as a guide for cutting bricks or blocks. Masons can mark a straight line on the surface of the material using the square, and then use a masonry saw or chisel to cut along the marked line. This ensures accurate and clean cuts, resulting in precise fitting of the bricks or blocks during construction. The steel square can also be utilized to measure and mark angles other than 90 degrees. By aligning the square with one side of the angle, masons can easily transfer the angle's measurement onto the surface of the material. This technique is particularly useful when constructing arches or decorative features that require precise angle measurements. Additionally, the steel square can serve as a leveling tool. Masons can place the square on a flat surface and use a level to ensure that it is perfectly horizontal or vertical. This is crucial for maintaining proper alignment and symmetry in the masonry work. Overall, the steel square is an indispensable tool in masonry, offering various techniques for ensuring accuracy, precision, and structural stability in the construction process.

- Q: How do you use a steel square to lay out a right angle?

- In order to lay out a right angle using a steel square, a few steps must be followed. To begin, place the square on a flat surface, such as a workbench or table, ensuring that the long side of the square (also referred to as the blade) is aligned with the edge of the surface. Following that, use a ruler or measuring tape to measure the desired length for one side of the right angle. For instance, if you wish to create a right angle with sides measuring 6 inches, mark the 6-inch point on the surface using a pencil or marker. After marking the desired length, slide the square along the surface until the blade aligns with the mark made. The blade should be perpendicular to the edge of the surface, forming a 90-degree angle. To complete the layout of the right angle, utilize the blade of the square as a guide and draw a line along its edge. This line will be perpendicular to the edge of the surface, thereby creating a right angle. Ensure that the square is held firmly in place while drawing the line to maintain accuracy. Confirm the angle by double-checking it with a protractor or another reliable method to ensure that it measures 90 degrees. By adhering to these steps, a steel square can be effectively used to lay out a right angle with precision and accuracy.

- Q: How do you use a steel square to mark out parallel lines on curved surfaces?

- To use a steel square to mark out parallel lines on curved surfaces, you will need to follow a few steps: 1. Choose the appropriate size steel square for your project. The size of the steel square will depend on the scale and curvature of the surface you are working with. 2. Place the steel square against the curved surface, ensuring that one edge of the square aligns with the desired starting point of the parallel line. 3. Use a pencil or marker to trace along the other edge of the steel square, marking the first parallel line. 4. Slide the steel square along the curved surface, aligning the marked line with the desired distance for the parallel lines. 5. Repeat the process of tracing along the other edge of the steel square, marking each parallel line at the desired distance. 6. Continue sliding and marking the steel square along the curved surface until you have marked out all the parallel lines you need. It's important to note that when working with curved surfaces, the parallel lines may not be perfectly straight due to the curvature. However, using a steel square will help you maintain a consistent distance between the lines, creating a visually pleasing and accurate result.

- Q: How do you use a steel square to determine the correct angle for a bevel cut?

- To use a steel square to determine the correct angle for a bevel cut, you align the long edge of the square with the edge of the material you want to cut. Then, you adjust the square until the desired angle is achieved. Once the square is in position, you can mark the angle on the material to guide your bevel cut.

- Q: How does a steel square assist in determining the correct angle for a half-blind dovetail joint?

- A steel square assists in determining the correct angle for a half-blind dovetail joint by providing a precise and accurate measurement tool. It allows woodworkers to align the square with the edges of the wood to ensure that the angle of the joint is exactly 90 degrees. This helps in achieving a clean and tight fit for the half-blind dovetail joint, ensuring a strong and sturdy connection between the pieces of wood.

- Q: What are the common mistakes to avoid when using a steel square in construction?

- When using a steel square in construction, it is important to be aware of some common mistakes that can occur. Here are a few mistakes to avoid: 1. Incorrect alignment: One common mistake is not properly aligning the steel square with the edge or surface you are trying to measure or mark. This can lead to inaccurate measurements and cuts. Always ensure that the square is aligned correctly before making any markings or cuts. 2. Inconsistent pressure: Another mistake is applying inconsistent pressure when using the square. This can result in uneven or inaccurate markings. It is crucial to apply a consistent and firm pressure when using the square to ensure accuracy. 3. Neglecting to check for squareness: It is important to regularly check the square for squareness. Over time, the square may become warped or bent, which can affect the accuracy of measurements. Regularly inspect the square and ensure it is still true and square. 4. Overlooking the use of the notch: Many steel squares have a notch or cutout on one side. This notch is designed to allow for accurate marking and measurement of angles. It is essential to utilize this feature when needed to ensure precise angles and cuts. 5. Ignoring the importance of maintenance: Steel squares can become rusty or dirty if not properly maintained. It is essential to keep the square clean and dry to prevent rust and corrosion. Regularly inspect the square for any signs of damage or wear and address any issues promptly. By being cautious and avoiding these common mistakes, you can effectively use a steel square in construction and ensure accurate measurements, markings, and cuts.

- Q: How do you use a steel square to mark out parallel lines on uneven surfaces?

- To use a steel square to mark out parallel lines on uneven surfaces, you would first place the square on the surface with one edge aligned with the desired starting point of the parallel lines. Then, using a pencil or scribe, mark a line along the edge of the square. Next, move the square along the surface, aligning the marked line with the opposite edge of the square, and mark another line. Repeat this process until you have marked out all the parallel lines you need. The steel square helps maintain the parallel alignment despite the unevenness of the surface.

- Q: Can a steel square be used for retaining wall layout and construction?

- Yes, a steel square can be used for retaining wall layout and construction. Steel squares are typically used in construction for layout and measuring purposes, and they can also be used to ensure accurate angles and measurements when constructing a retaining wall.

- Q: How do you use a steel square to measure and mark compound angles?

- To use a steel square to measure and mark compound angles, you need to follow these steps: 1. Set the steel square on the workpiece, aligning the long edge with the reference edge or surface. 2. Adjust the square to the desired angle by pivoting it around the reference edge. Ensure that both the blade and tongue of the square are parallel to the corresponding angled surfaces you want to measure or mark. 3. Once the square is set, use a pencil or marking tool to trace along the edges of the blade and tongue, marking the compound angle on the workpiece. 4. If you need to transfer the compound angle to another piece, repeat the above steps using the marked workpiece as the new reference edge. By carefully aligning and adjusting the steel square, you can accurately measure and mark compound angles on various woodworking or metalworking projects.

Send your message to us

Hot Rolled Carbon Steel Square Bar with Many Sizes

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords