Hot-rolled Square Steel Bar

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50Tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

Specifications of Hot-rolled Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

-Chemical Composition:

|

Standard |

Grade |

Element (%) | ||||

|

C |

Mn |

S |

P |

Si | ||

|

GB |

Q195 |

0.06~0.12 |

0.25~0.50 |

≤0.050 |

≤0.045 |

≤0.30 |

|

GB |

Q235B |

0.12~0.20 |

0.30~0.70 |

≤0.045 |

≤0.045 |

≤0.30 |

-Mechanical Properties:

|

Mechanical Properties |

Grade |

Steel diameter(mm) | |||

|

≤16 |

16~40 |

40~60 |

60~100 | ||

|

Yield Point Δs/MPa |

Q195 |

≥195 |

≥185 |

- |

- |

|

Q235 |

235 |

225 |

215 |

205 | |

|

Tensile Strength |

Q195 |

315~390 | |||

|

Q235 |

375~500 | ||||

|

Elongation δ5% |

Q195 |

≥33 |

≥32 |

- |

- |

|

Q235 |

26 |

25 |

24 |

23 | |

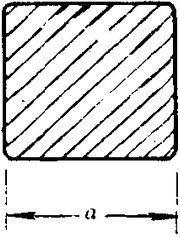

Measures of Hot-rolled Square Steel Bar (Big measures):

(Section of Hot-rolled Square Steel Bar)

-Length of a side and Theoretical weight of Square Bar (Big measures).

|

Length of a side(mm) |

Theoretical weight(kg/m) |

Length of a side(mm) |

Theoretical weight(kg/m) |

|

53 |

22.05 |

80 |

50.24 |

|

56 |

24.61 |

85 |

56.72 |

|

60 |

28.26 |

90 |

63.59 |

|

63 |

31.16 |

95 |

70.85 |

|

70 |

38.49 |

100 |

78.50 |

|

75 |

44.16 |

|

|

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

|

Steel |

Length of a side (mm) |

Length of steel (m) |

|

Normal steel |

< 25 |

4~10 |

|

> 25 |

3~9 | |

|

Steel of high quality |

All measure |

2~6 |

|

Tool steel >75 |

1~6 |

Usage/Applications of Hot-rolled Square Steel Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Packaging & Delivery of Hot-rolled Square Steel Bar:

-Packing Detail:

1, The products can be packed in bundles by steel wires.

2, The weight of each bundle no exceed normally 3 tons.

-Marks: We make tag marks and color marks for each bundle. The tag marks with white background and red company log will be tied up to each bundle. The information is usually including basic information of company and products like product name, specification, etc...and other information required by customers. As for color marks, we will paint both ends of each bundles to make sure that it will be more convenient for customers to distinguish theme from other products.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

-The payment terms will be written in contraction detailedly.

Photos of Hot-rolled Square Steel Bar:

We sincerely welcome partners around the world to establish business cooperation with us on the basis of mutual trust, benefit and development.

- Q: What are some common materials used in the construction of a steel square?

- Some common materials used in the construction of a steel square include stainless steel, carbon steel, and aluminum.

- Q: Can a steel square be used for gazebo layout and construction?

- Yes, a steel square can be used for gazebo layout and construction. Steel squares are versatile tools that can be used for measuring angles, marking out straight lines, and ensuring accurate right angles during construction. They provide stability and durability, making them suitable for various construction projects, including gazebo layout and construction.

- Q: Can a steel square be used for measuring and marking compound bevel, miter, and crown molding cuts?

- Yes, a steel square can be used for measuring and marking compound bevel, miter, and crown molding cuts. Steel squares are commonly used in carpentry and woodworking for their accuracy and versatility. They can help ensure precise measurements and angles, making them suitable for various types of cuts, including compound bevel, miter, and crown molding cuts.

- Q: How do you use a steel square to determine the angle of a compound miter cut?

- To use a steel square to determine the angle of a compound miter cut, you will need to follow a few steps. First, place the steel square against the edge of the material you will be cutting. Ensure that the long side of the square is perpendicular to the edge of the material. Next, find the desired angle for the miter cut. This may be specified in the project plans or determined by your own preferences. Once you have determined the angle, use a pencil or marker to mark a line on the material along the edge of the steel square. This line will indicate the angle for the miter cut. Now, rotate the steel square to align the long side with the newly marked line. The short side of the square should now be perpendicular to the edge of the material. At this point, you can use a protractor or angle finder tool to measure the angle between the short side of the square and the edge of the material. This will give you the exact angle for the compound miter cut. Alternatively, if you do not have a protractor or angle finder tool, you can use the markings on the steel square to estimate the angle. Most steel squares have degree markings along the short side, allowing you to measure the angle directly. Once you have determined the angle, use a miter saw or other appropriate cutting tool to make the compound miter cut according to your measurements. Remember to always wear appropriate safety gear and follow proper cutting techniques when using power tools.

- Q: Can a steel square be used for checking right angles?

- Indeed, a steel square has the capability to verify the presence of right angles. This multifunctional and dependable tool, also referred to as a framing square or carpenter's square, is extensively utilized in woodworking, construction, and other trades. It consists of a lengthy blade and a shorter tongue, which intersect at a precise 90-degree angle, thereby creating a flawless right angle. By positioning the square against the two surfaces that are expected to be perpendicular to each other, one can effortlessly ascertain the authenticity of the angle being 90 degrees. The steel square's precision and sturdiness render it an outstanding instrument for examining and guaranteeing right angles in a variety of applications.

- Q: How do you use a steel square to measure and mark 45-degree angles?

- To measure and mark 45-degree angles using a steel square, align the long edge of the square with the edge of the material you want to mark. Then, locate the 45-degree angle mark on the square and position it on the material. Once it is in the desired position, use a pencil or scribe to mark along the edge of the square, creating a precise 45-degree angle.

- Q: Can a steel square be used for measuring angles other than right angles?

- No, a steel square is specifically designed for measuring right angles and cannot accurately measure angles other than right angles.

- Q: What are the common materials used to make a steel square?

- The common materials used to make a steel square include steel, aluminum, and sometimes brass or wood for the handle.

- Q: How do you use a steel square to determine roof valley angles?

- To use a steel square to determine roof valley angles, you will need to follow a few steps. First, ensure that your steel square is clean and free from any debris or rust that may affect its accuracy. Next, locate the area where the roof valley is situated. This is the point where two roof sections meet at an angle, creating a valley. Place the steel square vertically against one side of the valley, ensuring that the square's edge aligns with the roof section. Hold the square firmly in place. Now, look at the measurements marked on the steel square. Most steel squares have a scale on one of the inside edges, which consists of numbers and angles. Find the angle measurement that corresponds to the roof valley angle you want to determine. Once you have identified the correct angle on the scale, rotate the square until the edge aligned with the roof section intersects with the corresponding angle measurement on the scale. Now, hold the square in this position and observe where the other edge of the square intersects with the other roof section. This point of intersection will give you the angle of the roof valley. You can then use this angle measurement to make accurate cuts or adjustments when installing or repairing the roof valley. It is important to note that the accuracy of the measurement depends on the precision of your steel square and your ability to align it properly with the roof sections.

- Q: How do you use a steel square for marking stair tread and riser dimensions?

- To use a steel square for marking stair tread and riser dimensions, follow these steps: 1. Start by measuring the total rise of the stairs, which is the vertical distance from the top of the landing to the finished floor level. Note down this measurement. 2. Next, determine the desired height of each riser. This can be calculated by dividing the total rise by the number of risers. For example, if the total rise is 48 inches and you want 6 risers, each riser should be 48/6 = 8 inches high. 3. Now, take your steel square and place it on a flat surface. Position the long edge of the square vertically, ensuring it is perpendicular to the surface. 4. Align the bottom corner of the square with the edge of the material you are marking, such as a piece of wood or the stringer on the stairs. 5. With the square held firmly against the material, use a pencil or marking knife to draw a line along the inside edge of the square. 6. For marking the tread dimensions, use the inside edge of the square to measure and mark the desired depth of each tread. The tread depth can be calculated by subtracting the riser height from the desired total run (the horizontal distance covered by the stairs). For instance, if you want a total run of 72 inches and have 6 risers, each tread should be 72/6 = 12 inches deep. 7. Repeat this process for each riser and tread, ensuring that the square remains held firmly against the material to maintain accuracy. Using a steel square for marking stair tread and riser dimensions allows for precise and consistent measurements, resulting in well-balanced and safe stairs. Remember to always double-check your measurements before cutting or installing any materials.

1. Manufacturer Overview

| Location | Renqiu, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 30 Million |

| Main Markets | Mid East; Southeast Aisa |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 20% - 30% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 70,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average |

Send your message to us

Hot-rolled Square Steel Bar

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50Tons m.t.

- Supply Capability:

- 500 tons per month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords