Hot Rolled Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering Hot rolled Square Steel at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

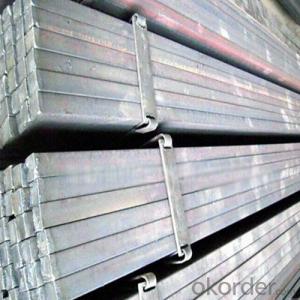

-The Square Steel is hot rolled,

-Standard: GB,

-Grade: Q195 or equivalent.

(The section of Square Steel)

Some details of Square Steel:

-List 1.The length of a side and the theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 70 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-List 2. The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

≤0.12 | ≤0.50 | ≤0.04 | ≤0.035 | ≤0.3 | ||

-Method of deoxidation: F, b, Z

Product Applications:

Hot rolled Square Steel are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Hot rolled Square Steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

Product Specifications:

Standard: GB

Material: Q235

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

bdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Images:

- Q: How do you use a steel square to determine the angle of a compound miter cut?

- In order to determine the angle of a compound miter cut using a steel square, there are a few steps that need to be followed. Firstly, position the steel square against the edge of the material that will be cut. Make sure that the long side of the square is perpendicular to the edge of the material. Next, locate the desired angle for the miter cut. This can be specified in the project plans or chosen based on personal preferences. After determining the angle, use a pencil or marker to draw a line on the material along the edge of the steel square. This line will serve as a guide for the miter cut. Now, rotate the steel square so that the long side aligns with the newly marked line. The short side of the square should now be perpendicular to the edge of the material. At this stage, a protractor or angle finder tool can be used to measure the angle between the short side of the square and the material's edge. This measurement will provide the exact angle for the compound miter cut. Alternatively, if a protractor or angle finder tool is not available, the markings on the steel square can be utilized to estimate the angle. Most steel squares have degree markings along the short side, allowing for direct angle measurement. Once the angle has been determined, a miter saw or other suitable cutting tool can be used to make the compound miter cut according to the measurements. Always remember to wear proper safety gear and adhere to correct cutting techniques when employing power tools.

- Q: Can a steel square be used for checking the squareness of picture hanging systems?

- Yes, a steel square can be used for checking the squareness of picture hanging systems. A steel square is a tool commonly used in carpentry and woodworking to ensure accuracy and squareness. It has a right angle shape and provides a reliable reference for measuring and checking squareness. By placing the steel square against the edges of the picture hanging system, you can determine if it is properly aligned and perpendicular to the wall.

- Q: How do you use a steel square to lay out a pentagon?

- To use a steel square to lay out a pentagon, start by marking a straight line on the material. Then, position the steel square on the line with one leg aligned with the edge. Use the other leg to mark the desired length of one side of the pentagon, making a perpendicular line from the first line. Repeat this step four more times, connecting the marks to form the pentagon's shape.

- Q: How do you use a steel square to determine the angle of a valley rafter cut?

- To use a steel square to determine the angle of a valley rafter cut, you would first place the square on the edge of the rafter and align one arm with the top edge of the rafter. Then, you would pivot the square until the other arm aligns with the bottom edge of the rafter. The angle indicated on the square where the bottom edge intersects is the angle of the valley rafter cut.

- Q: Can a steel square be used for measuring the depth of a well?

- No, a steel square cannot be used for measuring the depth of a well. The steel square is primarily used for measuring and marking right angles, not for measuring depth.

- Q: How do you use a steel square to find the length of a stair riser?

- To use a steel square to find the length of a stair riser, you would place the square against the vertical riser and the horizontal tread. By aligning the square's 90-degree angle against the riser and tread, you can measure the length of the riser directly on the square's blade. This allows for accurate and precise measurements for the length of the stair riser.

- Q: What are the uses of a steel square in construction?

- A steel square, also known as a framing square or carpenter's square, is a versatile tool widely used in construction for various purposes. Some of the key uses of a steel square in construction are: 1. Measuring and marking: A steel square is primarily used for measuring and marking straight lines and angles accurately. It consists of two arms, one long and one shorter, forming a right angle. This allows for precise measurements and marking of 90-degree angles, ensuring straight and square cuts. 2. Layout and framing: Steel squares are essential for layout work in construction projects. They help carpenters and builders lay out and mark building components, such as walls, roofs, stairs, and door frames, ensuring proper alignment and dimensions. The square's edges and measurements allow for precise layout and framing, resulting in well-built structures. 3. Cutting and sawing: Steel squares are often used as a guide for cutting and sawing materials. By aligning the square with the edge of the material, it provides a straight and accurate reference line for cutting with a saw or other tools. This helps prevent errors and ensures clean and precise cuts, especially for tasks like cross-cutting or mitering. 4. Checking and testing: Steel squares are useful for checking and testing the accuracy and squareness of existing structures or finished components. By comparing the square's edges against existing angles or corners, builders can identify any discrepancies or misalignment that need correction. This helps maintain the structural integrity and overall quality of construction projects. 5. Plumbing and leveling: In addition to measuring angles, steel squares can also be used for plumbing and leveling tasks. For example, when installing cabinets or shelves, a square can be used to ensure the vertical alignment of the components. It can also be used to check the levelness of surfaces, such as countertops or floors, by comparing the square's edges to the surface. Overall, a steel square is an essential tool in construction due to its versatility and accuracy. Its uses range from measuring and marking to layout, cutting, checking, and leveling, making it indispensable for builders, carpenters, and other construction professionals.

- Q: Can a steel square be used for fence gate installation?

- Yes, a steel square can be used for fence gate installation. It can be used to ensure accurate measurements and angles during the installation process.

- Q: Can a steel square be used for tile layout?

- Tile layout can definitely benefit from the use of a steel square. This tool, also referred to as a framing square or a carpenter's square, is incredibly versatile and has many applications in layout tasks. One of its main uses is for marking right angles and checking for squareness. When it comes to tile layout specifically, a steel square is great for ensuring that tiles are laid out in straight lines and at perfect right angles. It can also be used to measure and mark the starting point for tile installation, as well as to verify if the tiles are properly aligned and square throughout the installation process. However, it's important to remember that while a steel square is useful, it should be utilized alongside other tile layout tools like a chalk line or a laser level. This combination guarantees accurate and precise tile installation.

- Q: How do you use a steel square to lay out a diamond shape?

- To use a steel square to lay out a diamond shape, start by marking a reference line on the material using the long arm of the square. Then, align the short arm of the square with the reference line and mark a point to the left and right of the reference line to create the width of the diamond. Next, rotate the square 45 degrees and align the short arm with the left point previously marked. Mark a point above and below the reference line to determine the height of the diamond. Repeat this step for the right point. Finally, connect the points to form the diamond shape.

Send your message to us

Hot Rolled Square Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords