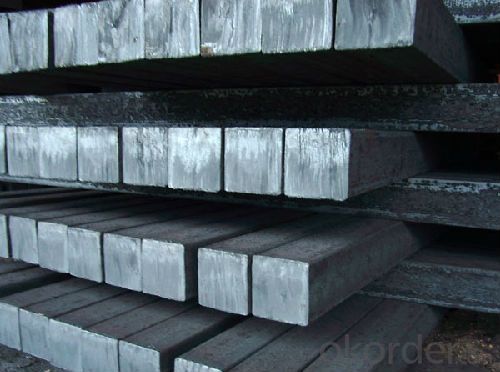

Prime Quality Mild Steel Square Billets and Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Prime Quality Mild Steel Square Billets and Square Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Prime Quality Mild Steel Square Billets and Square Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Prime Quality Mild Steel Square Billets and Square Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

We offer Square Steel Bar with grade Q195 / Q235

Specifications of Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

Chemical Composition:

-Chemical Composition. Q195

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

-Chemical Composition. Q235

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures and Tolerances of Square Steel Bar:

(The section of Square Steel Bar)

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Prime Quality Mild Steel Square Billets and Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Prime Quality Mild Steel Square Billets and Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

- Q: Can a steel square be used for checking the alignment of ceiling tiles?

- Yes, a steel square can be used for checking the alignment of ceiling tiles. A steel square is a versatile tool that is commonly used in carpentry and woodworking for measuring and marking right angles. Its straight edges and 90-degree angle make it suitable for ensuring the alignment and squareness of various objects, including ceiling tiles. By placing the steel square against the edges of the tiles, you can easily determine if they are properly aligned or if any adjustments need to be made. However, it's important to note that a steel square may not be the most convenient tool for larger areas or ceilings with a complex layout, as it is a handheld tool and may require multiple measurements. In such cases, a laser level or specialized tile alignment tools may be more efficient.

- Q: Can a steel square be used for framing a building?

- Yes, a steel square can be used for framing a building. Steel squares, also known as framing squares or carpenter squares, are versatile tools that are commonly used in construction and carpentry. They are typically made of steel and have a 90-degree angle, with additional markings and measurements along the edges. While traditional framing squares are often made of aluminum or steel and are commonly used in wood framing, steel squares can also be used for framing buildings made of steel or other materials. The sturdy construction of a steel square makes it durable and reliable for various framing tasks. It can be used to lay out and mark precise angles, measure and check squareness, and ensure accurate cuts and joints during the framing process. Steel squares are useful for determining the squareness of walls, checking the alignment of framing members, and laying out the positions of studs, rafters, and other structural components. They can also be used to mark and cut notches, birdsmouths, and other complex shapes on framing materials. Overall, a steel square is a valuable tool for framing a building, regardless of the material being used. Its accuracy, durability, and versatility make it an essential tool for any construction project.

- Q: How do you use a steel square to measure the height of a step?

- In order to measure the height of a step using a steel square, the following steps can be followed: 1. Position the steel square perpendicularly on the edge of the step, with the longer side parallel to the ground. 2. Slide the square along the vertical face of the step until the shorter side touches the top edge. 3. Once the square is correctly positioned, take note of the measurement on the longer side where it intersects with the top edge. This measurement will indicate the step's height. 4. Ensure the square is securely held to prevent any movement during the measurement process. It is also important to accurately read the measurement. 5. Repeat this process for each step to consistently measure the height.

- Q: How do you use a steel square to determine the slope of a ramp?

- To determine the slope of a ramp using a steel square, you can place the square vertically against the ramp and align it with the surface. Then, using a level, ensure that the square is perfectly vertical. Next, measure the distance from the bottom of the square to the ramp surface at the point where the square is aligned. This measurement will give you the rise of the ramp. Finally, measure the distance from the bottom of the square to the point where the ramp ends. This measurement will give you the run of the ramp. Dividing the rise by the run and multiplying it by 100 will give you the slope of the ramp as a percentage.

- Q: How do you use a steel square to ensure the correct angle for a dowel joint?

- To use a steel square to ensure the correct angle for a dowel joint, follow these steps: 1. First, measure and mark the location where you want to make the dowel joint on both pieces of wood. Ensure that the marks align properly for a flush joint. 2. Take the steel square and position it on the edge of one of the pieces of wood, with one arm of the square resting against the face of the wood. 3. Align the other arm of the square with the desired angle for the dowel joint. For example, if you want a 90-degree angle, align the arm of the square perpendicular to the edge of the wood. 4. Once the square is properly aligned, use a pencil or a marking knife to draw a line along the edge of the square. This line will indicate the correct angle for the dowel joint. 5. Repeat the same process on the other piece of wood, ensuring that the angle lines align properly when the two pieces are brought together. 6. Now, you can drill the dowel holes along the marked lines on each piece of wood. The dowel holes should be drilled perpendicular to the surface of the wood, using the marked lines as a guide. 7. Finally, apply glue to the dowels and insert them into the holes, joining the two pieces of wood together. Clamp the joint tightly and allow the glue to dry according to the manufacturer's instructions. By using a steel square to accurately mark the correct angle for the dowel joint, you can ensure a strong and precise connection between the two pieces of wood.

- Q: What are some common uses for a steel square in box joint construction?

- A steel square is an essential tool in box joint construction and is used for a variety of purposes. Some common uses for a steel square in box joint construction include: 1. Layout and marking: A steel square is used to accurately mark and measure the dimensions of the box joint. It helps in setting up the appropriate size and spacing of the finger joints and ensures precision in the layout. 2. Checking for squareness: The steel square is utilized to check the squareness of the corners in box joint construction. This ensures that the joints are perfectly perpendicular and will result in a strong and sturdy box. 3. Aligning and guiding: When assembling the box joint, a steel square can be used to align and guide the pieces together. It helps to maintain the correct angle and ensures that the joints fit snugly, resulting in a tight and secure box. 4. Testing for flatness: The steel square can also be used to test the flatness of the joint surfaces. By placing the square against the surfaces, any gaps or irregularities can be detected and corrected before final assembly. 5. Cutting and sawing: A steel square can be used as a guide for cutting and sawing the box joint. It provides a straight edge for the saw or router, ensuring clean and accurate cuts along the joint lines. Overall, a steel square is an indispensable tool in box joint construction. It helps in layout, alignment, checking for squareness, and ensuring precision cuts, resulting in a well-fitted and strong box joint.

- Q: How do you use a steel square to determine the angle of a beading cut?

- In order to determine the angle of a beading cut using a steel square, it is essential to have a good understanding of the square's markings and measurements. Typically, a steel square consists of two arms that are joined at a 90-degree angle, with one arm being longer than the other. The longer arm is called the blade, while the shorter arm is referred to as the tongue. To ascertain the angle of a beading cut, follow these step-by-step instructions: 1. Position the blade of the steel square against the surface where the cut will be made, ensuring that it is perfectly aligned with the edge of the material. 2. Securely hold the square in place, making certain that it remains stationary throughout the process. 3. Examine the markings on the tongue of the square. Most steel squares feature degree measurements and fractions of an inch. 4. Locate the degree measurement that is closest to the desired angle for your beading cut. 5. Once you have identified the closest degree measurement, use a pencil or marker to mark that angle on the material. 6. Carefully remove the steel square, ensuring that the marked angle remains clearly visible on the material. 7. Utilize a straight edge or ruler to connect the marked angle with the desired length of the beading cut. 8. Before proceeding with the cut, double-check your measurements and angles to ensure accuracy. 9. If you possess a power tool, such as a miter saw or circular saw, adjust the blade to the desired angle and proceed with making the cut. 10. If you are performing the cut manually, utilize a coping saw or hand saw to meticulously follow the marked angle and execute the beading cut. Always prioritize safety when working with tools and machinery. Verify your measurements, wear appropriate safety gear, and operate in a well-ventilated area.

- Q: Can a steel square be used for checking the squareness of window openings?

- Yes, a steel square can be used for checking the squareness of window openings.

- Q: How do you use a steel square to determine the angle of a tapering cut?

- To use a steel square to determine the angle of a tapering cut, you can follow these steps: 1. Begin by placing the steel square on the material you want to cut, ensuring that one of the sides of the square is aligned with the edge of the material. 2. Use a pencil or a marker to draw a line along the edge of the steel square that runs parallel to the material's edge. 3. Slide the steel square along the material, maintaining the alignment of one side of the square with the edge of the material. 4. As you slide the square, observe the point at which the drawn line starts to deviate away from the edge of the material. This deviation indicates the tapering angle. 5. Take note of the distance from the original line to the point of deviation. This distance will help you determine the angle of the tapering cut. 6. You can then use a protractor or a specialized taper jig to measure the angle based on the distance you noted. Alternatively, you can refer to a tapering angle chart or use a digital angle finder tool. Keep in mind that using a steel square to determine the angle of a tapering cut may not be as precise as using more specialized tools. It is always recommended to double-check your measurements and make test cuts on scrap material before proceeding with your actual project.

- Q: What are some common uses of a steel square in welding?

- A steel square is a versatile tool that finds numerous applications in welding. Some common uses of a steel square in welding include: 1. Checking Right Angles: A steel square is primarily used to ensure that the welded joints are at perfect right angles. It helps in maintaining the structural integrity of the welded workpiece. 2. Measuring and Marking: Steel squares have graduated scales along their edges, which allow welders to measure and mark different lengths accurately. This helps in ensuring precise dimensions for the welded components. 3. Layout and Layout Squares: Steel squares are often used in layout work to mark and layout patterns, templates, and cut lines on metal surfaces. Welders can use a steel square to create perpendicular lines, parallel lines, or to scribe circles and arcs. 4. Checking Alignment: Steel squares are handy in checking the alignment of welded components. Whether it is ensuring that two pieces are perfectly aligned before welding or checking the alignment of a welded joint, a steel square can help achieve accurate alignment. 5. Checking Flatness and Squareness: Welders often use steel squares to check the flatness and squareness of welded surfaces. By placing the square against the surface or the weld, they can determine if the welded area is flat or if the edges are square. 6. Welding Table Setup: Steel squares are useful in setting up welding tables. They can be used to align and square the table's framework, ensuring a stable and level surface for welding operations. 7. Fabrication and Assembly: Steel squares are commonly used in the fabrication and assembly of welded structures. They aid in positioning and aligning components during the welding process, resulting in accurate and strong welds. Overall, a steel square is an essential tool in a welder's arsenal, providing accuracy, precision, and reliability in various welding applications.

Send your message to us

Prime Quality Mild Steel Square Billets and Square Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords