11mm*0.95kg/m square bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications

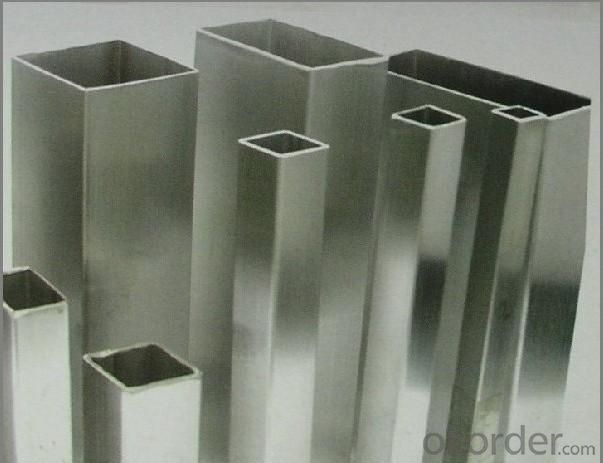

stainless steel square bar flat steel bar

Diameter:2-500mm

Length:Customized

Quality: High quality stainless steel bar

stainless steel square bar flat steel bar

Stainless Steel bar

Diameter:2-160mm

Length: Customized

Surface | bright,black |

Technique | Hot Rolled/Cold Drawn/Peeled |

1.Round bar 1Hot rolled black bar: (5~400x6000mm or according to your requirement. 2Acid round bar: (5~400)x6000mm or according to your requirement. 3Cold drawn bright bar: (1~20x6000mm or according to your requirement. 4)Polishing round bar: (5-400)x6000mm or according to your requests. | |

2. Square bar 1)Hot rolled black bar: (5*5-400*400)x6000mm or according to your requests. 2)Acid square bar: (5*5-400*400)x6000mm or according to your requests. 3)Cold drawn square bar: (1*1-20*20)x6000mm or according to your requests 4)Polishing square bar: (5*5-400*400)x6000mm or according to your requests | |

Diameter± | H9 tolerance can reach the industry standard |

Quality | Our production equipment 24 hours of continuous temperature work, to ensure the unity of the product roundness, elongation, tensile strength and yield strength. Welcome customers to our company to detect the products before shipment. For the customers who are not inconvenient, quality assurance can be laid down in the contract, we will take charge of the returning and shipping fee if there is any problems of the product quality, so it will dismiss any of your worry about our products. |

Package | Standard seaworthy packing(plastic&wooden) or according to the customer's requests |

Delivery time | 7-20days, according to the quantity |

Productivity | 10000 tons/month |

Stainless steel round bars:

Grade :200 series 300series 400series. (Standard: ASTM JIS DIN & BS)

Diameters: 4mm-300mm

Surface : white acid , annealed, black(hot rolled) , bright and following customers request.

Length: 6M(standard) or random

Packing: standard export packing or following customer’s demand.

- Q: How do you use a steel square to find the rise and run of stairs?

- To accurately determine the rise and run of stairs, one can utilize a steel square and proceed as follows: 1. Begin by measuring the total rise, which represents the vertical distance between the levels that the stairs will connect. This measurement can be taken from the upper floor's top surface to the lower floor's top surface. 2. Next, ascertain the desired number of risers. Divide the total rise by the desired riser height (typically between 6 to 8 inches) to obtain the number of risers required. Round the result to the nearest whole number. 3. To determine the number of treads, subtract 1 from the previously calculated number of risers. This adjustment accounts for the fact that the topmost step does not necessitate a tread, as it connects directly to the upper floor. 4. Divide the total run, which represents the horizontal distance the stairs will span, by the number of treads derived in the previous step. This calculation will yield the run measurement for each individual tread. 5. Employ the steel square by affixing it to the edge of a tread, ensuring that the 90-degree corner aligns with the tread's edge. 6. Slide the square along the tread until the desired tread depth (e.g., the 7-inch mark) on the square's inside edge aligns with the front edge of the tread. 7. Once properly aligned, mark the position of the square's outside edge on the tread. This marking denotes the run measurement for that particular tread. 8. Repeat this process for each tread, diligently aligning the square and accurately marking the run measurement. By adhering to these steps and utilizing a steel square, one can effectively determine the rise and run of stairs, guaranteeing a secure and comfortable staircase design.

- Q: How do you use a steel square to mark a line at a specific angle to a board?

- To mark a line at a specific angle to a board using a steel square, follow these steps: 1. Determine the desired angle by either using a protractor or measuring it with a degree scale. 2. Position the steel square on the board, aligning the long edge (blade) with the board's edge. 3. Hold the steel square firmly against the board's edge, ensuring it is flush with the surface. Make sure the blade extends beyond the board's edge, where the marking will be made. 4. Find the scale on the steel square that corresponds to the desired angle. Typically, this is marked on the blade or tongue of the square. 5. Align the desired angle on the scale with the board's edge. This will position the square correctly for marking the line. 6. With the steel square securely in place, use a pencil or scribe to draw a line along the blade's edge. Ensure the marking is consistent and clear. 7. After marking the line, double-check its alignment and accuracy by measuring it with a ruler or tape measure. Remember to maintain a steady hand and apply appropriate pressure to achieve a clean and accurate marking. Practice and precision are crucial for effectively using a steel square to mark a line at a specific angle to a board.

- Q: Can a steel square be used for stair layout and construction?

- Yes, a steel square can be used for stair layout and construction. A steel square, also known as a framing square or carpenter's square, is a versatile tool that can be used for various tasks in woodworking and construction, including stair layout and construction. A steel square has two arms, one long and one short, that meet at a right angle. The long arm is typically 24 inches in length and the short arm is around 16 inches. This design allows for accurate measurements and angles to be marked and cut, making it suitable for stair layout and construction. When using a steel square for stair layout, it can be used to determine the rise and run of each step, as well as the overall dimensions of the stairs. By placing the square against the edge of a board or riser, the correct angles and lengths can be marked and cut accurately. In addition to layout, a steel square can also be used during stair construction. It can be used to ensure that the stringers, which are the diagonal supports that hold the steps, are cut and positioned correctly. By using the square to mark the angles and lengths on the stringers, precise and secure cuts can be made, resulting in a sturdy and well-constructed staircase. Overall, a steel square is a valuable tool for stair layout and construction. Its ability to accurately measure and mark angles and lengths makes it a reliable choice for creating safe and functional stairs.

- Q: What are the different markings on a steel square and their purposes?

- A steel square is a versatile tool used in carpentry and other trades for measuring, marking, and laying out angles. It consists of a long, straight blade with a perpendicular handle, forming an "L" shape. The blade of a steel square typically has several markings that serve different purposes. 1. Inch Markings: The most common markings on a steel square are the inch markings along the blade. These markings allow for precise measurements when measuring lengths or distances. They are typically marked in increments of 1/16th of an inch, providing accurate measurements for various construction tasks. 2. Degree Markings: Another important set of markings on a steel square are the degree markings found on the handle. These markings indicate the angles from 0 to 90 degrees, allowing for precise angle measurements. Degree markings are useful for tasks such as cutting or marking angles on wood or other materials. 3. Rafter Tables: Some steel squares feature rafter tables, which are additional markings on the blade. Rafter tables provide measurements and calculations for common roof framing tasks, such as determining the length of a rafter or the angles required for roof pitches. These tables save time and help ensure accurate measurements when working on roofing projects. 4. Brace Measurement: Steel squares often have markings on the inside of the handle that help measure the width of boards or other materials. These markings are useful for quickly determining the width of a piece of wood, ensuring accurate cuts or joints. 5. Scribe Lines: Along the blade of a steel square, there may be small indentations or notches called scribe lines. These lines are used for marking a cut or a line on a workpiece. By placing a pencil or a knife in the scribe line and sliding it along the edge of the square, precise and straight lines can be marked on the material. Overall, the different markings on a steel square serve to provide accurate measurements, assist in angle calculations, aid in rafter-related tasks, and facilitate marking straight lines. These markings make the steel square an essential tool for carpenters, builders, and anyone involved in construction or woodworking.

- Q: What are some common techniques for using a steel square in box making?

- Some common techniques for using a steel square in box making include measuring and marking right angles, checking for squareness during assembly, ensuring accurate cuts and joints, and aligning edges and corners for precise box construction.

- Q: Can a steel square be used for checking the plumbness of a post hole?

- Yes, a steel square can be used for checking the plumbness of a post hole. A steel square is a versatile tool that is commonly used in woodworking and construction. It has a 90-degree angle that can be aligned with the sides of the post hole to check for plumbness. By placing the steel square against the sides of the hole, one can determine if the walls are straight and vertical. If the steel square does not align properly, adjustments can be made to ensure the post is set in a plumb position. However, it's important to note that while a steel square can be helpful for initial checking, a more accurate measurement can be obtained by using a plumb bob or a level to ensure the post is perfectly vertical.

- Q: How do you use a steel square to measure and mark right angles?

- In order to measure and mark right angles using a steel square, one must initially position the long edge of the square against a side of the desired object or surface. It is crucial to ensure that the long edge is perfectly aligned with the side. Following that, the square must be slid along the side until the short edge of the square also touches the adjacent side. This action will generate a flawless 90-degree angle at the intersection of the two square edges. Once the square has been accurately positioned, either a pencil or a scribe can be utilized to mark the right angle on the surface. Simply trace along the edges of the square to establish a distinct and precise line. The steel square serves as a versatile tool, applicable in various fields such as woodworking, construction, and metalworking. It offers a dependable and accurate technique for ensuring the precise measurement and marking of right angles, thereby resulting in meticulous and professional work.

- Q: Can a steel square be used for surveying work?

- Yes, a steel square can be used for surveying work. A steel square, also known as a framing square or carpenter's square, is a versatile and reliable tool commonly used in construction and woodworking. While it may not be the most precise or accurate tool for surveying purposes, it can still be used in certain surveying tasks that do not require high levels of precision. For example, a steel square can be used to measure right angles, determine level and plumb lines, and establish basic alignments. However, for more precise and accurate surveying work, specialized surveying instruments such as total stations or GPS receivers would be more appropriate.

- Q: How do you use a steel square to measure board lengths?

- To measure board lengths using a steel square, here are the steps you should follow: 1. Align one side of the steel square with the end of the board, placing it on the edge of the board. 2. Check if both sides of the square touch the board's edge to ensure that the square is perfectly perpendicular to the board. 3. Securely hold the square against the board to prevent any movement. 4. Examine the measurements marked on the blade of the square. Most steel squares have measurements in inches, with one side indicating length and the other indicating width. 5. Determine the length of the board by reading the measurement on the blade where the opposite end of the board aligns. 6. Record the measurement for future reference or make a mark on the board. It is crucial to emphasize the importance of accuracy when measuring board lengths with a steel square. Ensure proper alignment between the board and the square, and firmly hold the square against the board to achieve precise measurements.

- Q: How do you use a steel square for marking roof gable angles?

- To use a steel square for marking roof gable angles, follow these steps: 1. Start by determining the desired pitch or slope for the gable. This is typically specified in terms of rise over run, such as 6/12 (for a 6-inch rise over a 12-inch run) or 8/12. 2. Next, position the steel square on the gable rafter. The long side of the square, called the blade, should align with the edge of the rafter, while the short side, called the tongue, should rest against the top of the rafter. 3. Adjust the steel square until the desired pitch or slope aligns with the edge of the rafter. You can do this by sliding the square up or down the rafter until the markings on the square indicate the desired pitch. 4. Once the steel square is properly positioned, use a pencil or marker to mark the angle on the rafter. You can do this by tracing along the tongue of the square or using a straight edge to extend the lines from the markings on the square. 5. Repeat this process for each gable rafter, ensuring that all angles are marked consistently. By using a steel square in this manner, you can accurately mark the angles for roof gables, ensuring that the roof is properly pitched and aligned. Remember to double-check your measurements and markings before making any cuts or adjustments to the rafters.

Send your message to us

11mm*0.95kg/m square bar for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords