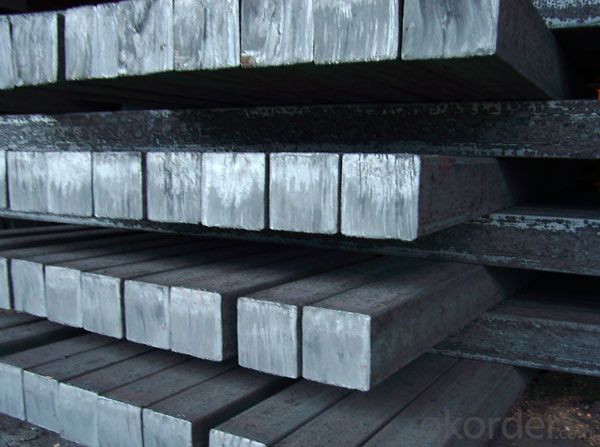

Alloyed steel square bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

hot rolled square steel billet

1.Q195 Q235 Q345B

2.terms of payment: L/C T/T

3.size: 100~150mm length: 5.8~12m

4.certificate:GB

Type | Steel billet |

Standard Grade | a. 3SP/PS |

b. Q235 | |

c. 5SP d. Q275 | |

Size | 120mm x 120mm-150mm x 150mm etc. as per customers' requirement |

Length | 12m as standard |

Application | Carbon structural steel, Alloy steel, Gear steel, etc. |

Packing | standard export packing, or as per customers' requirement |

Quality | First quality |

Delivery time | Right now after the deposit. |

Others | 1. our products conform to all the standards |

2. we can offer special specification products as per our customers | |

3. we can offer the original mill test certificate and original production |

- Q: Can a steel square be used for checking the squareness of a router table top?

- Indeed, the squareness of a router table top can be assessed using a steel square. This tool is widely employed for verifying squareness and yielding precise measurements. Placing the steel square against the table top's edges guarantees their perpendicularity. By contrasting the table top's squareness with the steel square, any deviations or misalignments can be readily detected. This step is indispensable to guarantee the precision and accuracy of the router table since a flawless square table top is vital for attaining consistent and accurate cuts.

- Q: What are some common mistakes to avoid when using a steel square?

- When using a steel square, there are a few common mistakes that should be avoided to ensure accurate measurements and precise angles. Here are some of the most frequent errors: 1. Not checking for squareness: One of the common mistakes is assuming that the steel square is perfectly square and not double-checking its accuracy. It is essential to verify its squareness by comparing it to a known square or using a precision instrument like a digital angle gauge. 2. Improper placement: Incorrect placement of the steel square can lead to inaccurate measurements. It is crucial to ensure that the square is aligned properly with the workpiece or the surface being measured. Placing it firmly against the edge or corner is necessary to obtain accurate results. 3. Misreading measurements: Another common mistake is misreading the measurements on the steel square. These squares typically have various scales and markings on different sides, so it is important to familiarize yourself with how to read them correctly. Using the wrong scale or misinterpreting the markings can result in incorrect measurements. 4. Inconsistent pressure: When marking or scribing lines with a steel square, inconsistent pressure can lead to inaccurate results. Applying uneven pressure or not holding the square firmly against the workpiece can cause the square to shift, resulting in imprecise lines. 5. Neglecting to clean and maintain the square: Over time, dirt, dust, and rust can accumulate on the steel square, affecting its accuracy. It is essential to regularly clean and maintain the square to ensure that it functions properly. Using a soft cloth and a mild cleaning solution can help remove any debris or rust. 6. Not using the square for its intended purpose: Lastly, using the steel square for tasks it is not designed for can lead to mistakes. Steel squares are primarily used for measuring and marking right angles, so trying to use them for other angles or complex measurements may result in errors. It is important to choose the appropriate tool for the specific task at hand. By being aware of these common mistakes and taking the necessary precautions, you can effectively use a steel square and achieve accurate measurements and precise angles in your projects.

- Q: Can a steel square be used for checking the flatness of a wall stud?

- No, a steel square cannot be used for checking the flatness of a wall stud. A steel square is a measuring tool that is primarily used for marking and measuring right angles. It is not designed to assess the flatness or straightness of a surface. In order to check the flatness of a wall stud, a straightedge or a level should be used. These tools provide a more accurate measurement and can determine any irregularities or deviations in the surface.

- Q: Can a steel square be used for measuring door and window openings?

- A steel square, also called a framing square or carpenter's square, is a versatile tool widely employed in construction and carpentry. It is capable of measuring door and window openings accurately. This tool typically possesses a 90-degree angle and a lengthier blade, which serves the purpose of measuring and marking straight lines. Additionally, the shorter blade can be utilized for measuring various angles, including 45 degrees or 30 degrees. To ensure precise and square measurements, a steel square can be utilized when measuring door and window openings. By placing it against the edges of the opening, one can determine if they are perfectly perpendicular or if any adjustments are necessary. The width and height of the opening can be measured using the longer blade, while the shorter blade serves to verify if the corners are square. In conclusion, a steel square is a dependable tool that can be used to measure door and window openings, guaranteeing their proper alignment and squareness.

- Q: What are the different types of steel squares available on the market?

- On the market, one can find a variety of steel squares, each specifically designed for different purposes. Some commonly encountered types are as follows: 1. Engineer's Square: This square, larger in size, is utilized in engineering and metalworking to ensure precise right angles and measurements. 2. Combination Square: Featuring a 90-degree angle and a sliding blade or ruler, this versatile tool is useful for measuring, marking, and checking both 90-degree and 45-degree angles. 3. Try Square: Smaller in size, this square with a handle and a 90-degree angle is primarily employed in woodworking to verify the accuracy of right angles and to mark straight lines. 4. Rafter Square: Also referred to as a framing square, this square, larger and heavier than other types, is commonly used in carpentry and construction to lay out and cut roof rafters, stairs, and other angled cuts. 5. Speed Square: Compact and portable, speed squares, also known as rafter squares, serve multiple functions. With a 90-degree angle, a 45-degree angle, and a built-in protractor, they allow for the measurement and marking of various angles. 6. Carpenter's Square: Similar to a try square but larger and sturdier, this square is specifically designed for carpentry tasks such as checking for squareness, marking lines, and measuring angles. 7. Machinist's Square: Precision-engineered and frequently utilized in machining and metalworking, this square offers an accurate 90-degree angle for precise measurements and layout work. These examples showcase the variety of steel squares available on the market, each designed with unique features to cater to specific needs in industries such as engineering, woodworking, construction, and metalworking.

- Q: Can a steel square be used for checking the squareness of a router table?

- Yes, a steel square can be used to check the squareness of a router table. It can be placed against the router table's surfaces and edges to ensure that they are perfectly perpendicular and square.

- Q: How do you use a steel square to find roof pitch?

- To use a steel square to find roof pitch, you would first align the square's tongue along the bottom edge of the roof rafter. Then, rotate the square until the rafter's edge intersects with the square's pivot point. The measurement on the square's blade will indicate the roof pitch angle, allowing you to determine the slope or pitch of the roof.

- Q: Can a steel square be used for checking the squareness of a router table fence?

- Indeed, a router table fence's squareness may be assessed using a steel square. This tool, known for its dependability in angle measurement and guaranteeing the perpendicularity of two surfaces, proves useful. To evaluate the squareness of the router table fence, effortlessly position the steel square against both the fence and the table surface, ensuring a seamless fit against each. If the steel square flawlessly forms a 90-degree angle with both the fence and table, it signifies the fence's squareness. In the event of any disparity or a non-90-degree angle, appropriate adjustments can be made to correctly align the fence.

- Q: How do you use a steel square to determine the height of a countertop?

- To use a steel square to determine the height of a countertop, you need to follow a few simple steps: 1. Start by placing the steel square on top of the countertop, making sure it is aligned with one of the corners. The long side of the square should rest on the countertop surface. 2. Next, extend the square vertically until it reaches the desired height you want to measure. Ensure that the square is perfectly perpendicular to the countertop surface. 3. Once the square is in position, take a tape measure and measure the distance from the bottom of the square to the countertop surface. This measurement will give you the height of the countertop. 4. Repeat the process on each corner of the countertop to ensure accuracy. It is important to measure multiple points to account for any unevenness or irregularities in the countertop surface. By using a steel square and following these steps, you can accurately determine the height of a countertop. This method is particularly useful when you need precise measurements for installing appliances, cabinets, or any other elements that require a specific countertop height.

- Q: How is a steel square different from a framing square?

- Carpentry and construction employ versatile tools known as steel squares and framing squares. Despite their shared field of usage, these tools possess distinct designs and functions. A steel square, alternatively referred to as a rafter square or carpenter's square, is a compact handheld tool typically made of steel. It comprises two arms, namely the tongue (a shorter arm) and the blade (a longer arm), which meet at a perfect right angle. The blade, usually equipped with scales and markings, facilitates the measurement of angles and lengths. Steel squares excel in measuring and marking right angles, gauging the squareness of corners, and establishing or verifying angles for cutting purposes. Their application is particularly prevalent in tasks requiring meticulous precision, such as framing, roofing, and constructing staircases. Conversely, a framing square, also known as a carpenter's square, presents itself as a larger tool commonly constructed from aluminum or steel. It features an elongated arm called the blade and a shorter arm known as the tongue, both conjoined at a right angle. The blade possesses a wider surface area and often exhibits multiple scales and markings, enabling measurements of diverse angles, lengths, and cuts. Framing squares play a primary role in rough carpentry and framing endeavors, including the layout and marking of rafters, stairs, or walls. They prove indispensable in ensuring accuracy and consistency during measurements and cuts within extensive construction projects. To summarize, steel squares and framing squares, despite being valuable assets in the field of carpentry and construction, diverge in terms of their size, design, and purpose. A steel square is a compact handheld device, primarily employed for measuring and marking right angles. Conversely, a framing square is larger in size, frequently incorporating multiple scales, and utilized for precise measurements and cuts in rough carpentry assignments.

Send your message to us

Alloyed steel square bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords