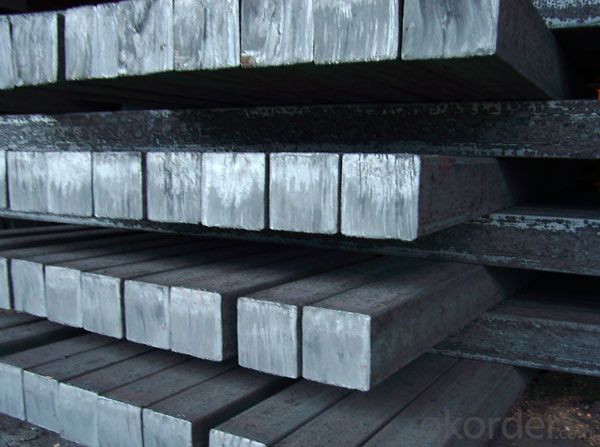

Alloyed square bar-Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

hot rolled square steel billet

1.Q195 Q235 Q345B

2.terms of payment: L/C T/T

3.size: 100~150mm length: 5.8~12m

4.certificate:GB

Type | Steel billet |

Standard Grade | a. 3SP/PS |

b. Q235 | |

c. 5SP d. Q275 | |

Size | 120mm x 120mm-150mm x 150mm etc. as per customers' requirement |

Length | 12m as standard |

Application | Carbon structural steel, Alloy steel, Gear steel, etc. |

Packing | standard export packing, or as per customers' requirement |

Quality | First quality |

Delivery time | Right now after the deposit. |

Others | 1. our products conform to all the standards |

2. we can offer special specification products as per our customers | |

3. we can offer the original mill test certificate and original production |

- Q: How do you use a steel square to measure the height of a countertop?

- To use a steel square to measure the height of a countertop, you would place one edge of the square against the underside of the countertop and extend it vertically until it reaches the desired height. Then, the measurement can be read from the markings on the square, providing an accurate measurement of the countertop's height.

- Q: Can a steel square be used for measuring pipe fittings?

- Indeed, pipe fittings can be measured using a steel square. By utilizing the straight edges of the square, one can guarantee that the fittings are perfectly perpendicular to one another. Furthermore, the square's 90-degree angle can be employed to confirm the correctness of the fitting's angles and ensure their proper alignment. Nevertheless, it is crucial to acknowledge that when precise measurements are required, or when factoring in possible discrepancies in pipe or fitting thickness, it may be more suitable to employ specialized measuring instruments like calipers or tape measures.

- Q: How do you use a steel square to measure board lengths at different points?

- To use a steel square to measure board lengths at different points, you would first align one edge of the square with the end of the board. Then, slide the square along the board until the desired measurement point aligns with the other edge of the square. Finally, read the measurement in inches or centimeters indicated on the square's markings at the aligned point to determine the board's length at that particular spot.

- Q: What are the different angles that can be measured with a steel square?

- A steel square can be used to measure various angles, including right angles (90 degrees), acute angles (less than 90 degrees), obtuse angles (greater than 90 degrees but less than 180 degrees), and straight angles (180 degrees).

- Q: What are some common uses for a steel square in cabinetry?

- A steel square, also referred to as a framing square or carpenter's square, holds great importance in cabinetry due to its versatility. It serves various purposes, some of which include: 1. Layout and marking tasks: In cabinetry, precise marking of straight lines, right angles, and exact measurements is crucial. A steel square aids in these tasks, ensuring accurate markings for different cuts and joints. 2. Checking for squareness: To guarantee proper alignment and fit in cabinetry, precise squareness is necessary. A steel square is employed to check the squareness of panels, corners, and joints, ensuring correct alignment of all components. 3. Marking and cutting angles: For many cabinetry projects, angled cuts are required, such as mitered corners or beveled edges. A steel square acts as a guide for marking and cutting precise angles, ensuring accurate achievement of desired angles. 4. Measurement and transferring measurements: Due to its straight edges and measurement scales, a steel square proves useful for measuring and transferring measurements in cabinetry. It enables precise measurements of lengths, widths, and depths, ensuring accuracy throughout the construction process. 5. Checking and marking for level and plumb: In order to ensure stability and proper functionality, cabinetry needs to be level and plumb. A steel square aids in checking and marking level and plumb lines, ensuring correct installation of cabinets. 6. Creating and checking right angles: Right angles play a fundamental role in cabinetry construction. A steel square facilitates the creation of right angles by aligning its edges with the workpiece, ensuring proper alignment and squareness of corners and joints. All in all, a steel square is an essential tool for any cabinetmaker or carpenter, offering accuracy in layout, measurement, and alignment. Its precision and versatility make it indispensable in the field of cabinetry.

- Q: Can a steel square be used for marking out tenon shoulders?

- Yes, a steel square can be used for marking out tenon shoulders. A steel square is a versatile tool that can be used for measuring and marking out precise angles and lines, making it suitable for marking the shoulders of a tenon. Its sturdy construction and accurate measurements ensure a clean and professional result.

- Q: How accurate are steel squares for measuring angles?

- Steel squares are generally very accurate for measuring angles. They are designed with precision and built to strict standards, ensuring that the angles they provide are reliable and consistent. However, their accuracy can be affected by factors such as wear and tear, misuse, or manufacturing defects. Therefore, it is important to regularly check and calibrate steel squares to ensure their accuracy. Overall, when used correctly and maintained properly, steel squares can be highly accurate tools for measuring angles.

- Q: How do you use a steel square for marking roof hip angles?

- To use a steel square for marking roof hip angles, you would start by placing the square on the edge of the roof hip. Align the tongue of the square with the hip and the body of the square with the roof surface. Then, using a pencil or scribe, mark the desired angle on the roof surface using the square as a guide. Repeat this process for each hip angle on the roof to ensure accurate markings.

- Q: How to make the steel arc

- The steel made arc:Solid steel:1, bending machine bend into arc2, flame cutting off arc baking3, bending machine coil windingHollow square:The hollow square filled with sand again by the method of solid steel bending arc.

- Q: What are some common measurements that can be taken with a steel square in sheet metal work?

- Some common measurements that can be taken with a steel square in sheet metal work include determining angles, checking for squareness, measuring the thickness of sheet metal, and marking straight and parallel lines. Firstly, a steel square can be used to measure and mark angles. By aligning the square's edge with the desired angle, one can accurately mark the sheet metal for cutting or bending. The square's markings, such as those for 45-degree or 90-degree angles, assist in achieving precise measurements. Secondly, a steel square is essential for checking squareness. It ensures that corners or edges of the sheet metal are perfectly perpendicular to each other. By aligning the square's edge against a corner and observing if the other edge aligns perfectly, one can determine if the sheet metal is square or if adjustments need to be made. Additionally, a steel square can be used to measure the thickness of sheet metal. By placing the square against the edge of the metal, one can read the measurement scale on the square to determine the thickness. This information is crucial for selecting appropriate tools, such as shears or punches, for cutting or shaping the sheet metal. Furthermore, a steel square is valuable for marking straight and parallel lines on sheet metal. By using the square's edge as a guide, one can draw precise lines that are parallel to an existing edge or at a specific distance from it. This is particularly important in sheet metal fabrication, where accuracy is crucial for the final product. In summary, a steel square is a versatile tool in sheet metal work, allowing for measurements of angles, checking squareness, measuring thickness, and marking straight and parallel lines. Its accuracy and reliability make it an essential instrument in achieving precise and high-quality sheet metal projects.

Send your message to us

Alloyed square bar-Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords