Steel Bars in Square Section with American Standard ASTM A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel Bar in Square Section description:

Steel bar in square section is a bar with square shaped cross-section. It is special case of equal sides. Before steel products are sold on the market, the steel must first be processed into more functional pieces. Raw steel cannot be of use while in its pure form, thus it has to be cast into shape. The freshly made steel, steel bar in square section is still in the form of a metal bar or rectangle. Small sizes of steel bar in square section are used in ship building.

2. Main Features of Steel Bar in Square Section:

• Grade: Q235

• Type: Mild carbon steel

• A quadrilateral with four equal sides and four right angles.

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

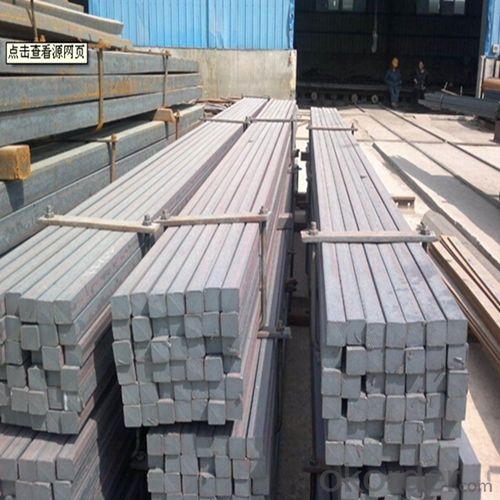

3. Steel Bar in Square Section Images:

4. Steel Bar in Square Section Specification:

Mechanical Properties | Grade | Steel diameter(mm) | |||

≤16 | 16~40 | 40~60 | 60~100 | ||

Yield Point Δs/MPa | Q195 | ≥195 | ≥185 | - | - |

Q235 | 235 | 225 | 215 | 205 | |

Tensile Strength | Q195 | 315~390 | |||

Q235 | 375~500 | ||||

Elongation δ5% | Q195 | ≥33 | ≥32 | - | - |

Q235 | 26 | 25 | 24 | 23 | |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①What is the main material?

There are two types of Square Bar, one is hot rolled square bar and other one is cold drawn square bar. Our principal products is hot rolled square bar. We dedicate to products with material Q195 and Q235. We offer products with high quality and low price.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How do you use a steel square to create half-lap joints?

- In order to create half-lap joints using a steel square, several steps must be followed: 1. Begin by marking the joint's location on both pieces of wood. Measure and mark the joint's width on each piece, ensuring proper alignment. 2. Prepare the steel square by placing it on the edge of one piece of wood, aligning the inner edge with the marked joint location. Ensure secure placement of the square. 3. Scribe lines along the inner edge of the steel square using a sharp pencil or knife. This will accurately transfer the measurement onto the wood. 4. Repeat the process on the second piece of wood, making sure the lines align with each other. 5. Carefully remove the material between the scribed lines on each piece of wood using a saw or chisel. Take your time and make precise cuts for a clean and accurate joint. 6. Test the fit by placing the two pieces together. They should fit tightly and securely without any gaps. 7. If the joint is not a perfect fit, make minor adjustments by removing more material or using a file to fine-tune the fit. Continually test and adjust until you achieve a snug and flush joint. Remember, mastering the technique of creating half-lap joints with a steel square requires practice and patience. It may take a few attempts to become proficient, but with time and experience, you will be able to produce strong and precise joints.

- Q: How do you use a steel square to find the square footage of a patio?

- To use a steel square to find the square footage of a patio, you can measure and mark the dimensions of the patio using the steel square. Once you have the length and width measurements, multiply them together to get the square footage of the patio.

- Q: How do you use a steel square for marking roof ridge angles?

- To use a steel square for marking roof ridge angles, first, position the square on the ridge board and align it with the top of the roof. Next, pivot the square until the desired angle is reached, ensuring that the square's edge aligns with the roof rafters. Finally, mark the angle on the ridge board and use it as a reference for cutting rafters or installing ridge beams.

- Q: What are some common uses for a steel square in box joint construction?

- A steel square is an essential tool in box joint construction and is used for a variety of purposes. Some common uses for a steel square in box joint construction include: 1. Layout and marking: A steel square is used to accurately mark and measure the dimensions of the box joint. It helps in setting up the appropriate size and spacing of the finger joints and ensures precision in the layout. 2. Checking for squareness: The steel square is utilized to check the squareness of the corners in box joint construction. This ensures that the joints are perfectly perpendicular and will result in a strong and sturdy box. 3. Aligning and guiding: When assembling the box joint, a steel square can be used to align and guide the pieces together. It helps to maintain the correct angle and ensures that the joints fit snugly, resulting in a tight and secure box. 4. Testing for flatness: The steel square can also be used to test the flatness of the joint surfaces. By placing the square against the surfaces, any gaps or irregularities can be detected and corrected before final assembly. 5. Cutting and sawing: A steel square can be used as a guide for cutting and sawing the box joint. It provides a straight edge for the saw or router, ensuring clean and accurate cuts along the joint lines. Overall, a steel square is an indispensable tool in box joint construction. It helps in layout, alignment, checking for squareness, and ensuring precision cuts, resulting in a well-fitted and strong box joint.

- Q: How do you use a steel square for creating accurate rabbet cuts?

- For achieving precise rabbet cuts, the following steps should be followed while utilizing a steel square: 1. Begin by measuring and marking the dimensions of the desired rabbet cut on the wooden surface, which includes both the width and depth of the rabbet. 2. Align one side of the steel square with the wooden edge, ensuring it is placed accurately on the wood. 3. While firmly holding the steel square in place with one hand, employ a pencil or marking knife to trace along the other side of the square. This will generate a straight and precise guideline for the rabbet cut. 4. Proceed to repeat this procedure on the adjacent side of the wood, employing the same measurement and aligning the square with the previously marked line. This will ensure parallelism and precision in the rabbet cut. 5. Utilize a chisel, router, or table saw to eliminate the material within the marked lines, following the straight guideline established by the steel square. It is crucial to take your time and make accurate cuts to accomplish a clean and precise rabbet. 6. Once the rabbet cut is completed, utilize the steel square once more to verify squareness and guarantee that the corners of the rabbet are at perfect right angles. By utilizing a steel square as a reference guide, accuracy and precision can be maintained in your rabbet cuts, ultimately resulting in well-executed and professional-looking woodworking projects.

- Q: Can a steel square be used for checking the squareness of a jointer table?

- Yes, a steel square can be used for checking the squareness of a jointer table. A steel square is a versatile and accurate tool that can be utilized for checking the squareness of various surfaces, including a jointer table.

- Q: What are some common measurements that can be taken with a steel square in electrical work?

- Some common measurements that can be taken with a steel square in electrical work include checking right angles, measuring and marking straight lines, finding the center point of a board or panel, determining the depth of a hole or conduit, and verifying the alignment of electrical boxes or fixtures.

- Q: How do you use a steel square to determine the angle of a molding cut?

- To use a steel square to determine the angle of a molding cut, you will need to follow a few simple steps. First, ensure that the steel square is clean and free from any debris or rust. This will ensure accurate measurements. Next, place the square on the edge of the molding, aligning one side of the square with the edge of the molding. Make sure the square is positioned in a way that the other side of the square is perpendicular to the edge of the molding. Once the square is properly positioned, locate the angle markings on the square. These markings are usually found on the inside corner of the square, where the two arms meet. Now, carefully read the angle measurement indicated on the square. This measurement will help you determine the angle at which the molding needs to be cut. If the angle indicated on the square is greater than 90 degrees, it means you need to make an obtuse angle cut. If the angle is less than 90 degrees, it indicates an acute angle cut. To make the cut, transfer the angle measurement from the square to your saw or miter box. Set the saw or miter box to the desired angle and carefully cut the molding along the marked line. Remember to always wear appropriate safety gear, such as goggles and gloves, when working with tools and sharp objects. Double-check your measurements and angle settings before making any cuts to ensure accuracy and precision.

- Q: Can a steel square be used for shed layout and construction?

- Yes, a steel square can definitely be used for shed layout and construction. Steel squares are versatile tools that can aid in accurately measuring and marking angles, distances, and lines. They are commonly used by carpenters and builders for various layout tasks such as determining right angles, marking out studs, and checking for squareness in construction projects like sheds. The durability and accuracy of a steel square make it a reliable tool for shed layout and construction purposes.

- Q: What are some common measurements that can be taken with a steel square in plumbing rough-ins?

- Some common measurements that can be taken with a steel square in plumbing rough-ins include determining angles for cutting pipes, checking for squareness and alignment of pipes and fixtures, measuring distances and dimensions accurately, and ensuring proper fit and alignment of pipes and fittings.

Send your message to us

Steel Bars in Square Section with American Standard ASTM A36

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords