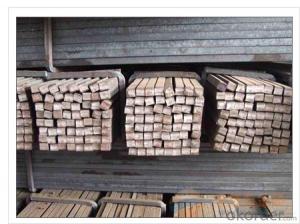

Hot Rolled Steel Square Bar with the Size 120mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Square Bar can be used as steel billet for other steel products like steel angles, channels, I-beams, H-beams, steel Rebar, steel wire rod etc.

Feature:

We have two kinds of Hot Rolled Steel Square Bar which is used as billet, one is produced by blast furnace, the other is produced by electrical arc furnace. The prices are different.

Detail Sizes:

120*120mm 113.18kg/m

Material Grade:Q235 Q275 3SP 5SP

FAQ:

Packing Detail: The products can be packed naked,loose

The products can be delivered by bulk vessel or by container

Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

- Q: How do you use a steel square to lay out a mortise and tenon joint?

- To use a steel square to lay out a mortise and tenon joint, you can follow these steps: 1. Start by marking the shoulder line on both the mortise and tenon pieces. This line determines how far the tenon will extend into the mortise. 2. Next, use the steel square to mark the thickness of the tenon on both the mortise and tenon pieces. This ensures that the tenon will fit snugly into the mortise. 3. Use the square to mark the width of the tenon on the end of the tenon piece. This will indicate how wide the mortise needs to be. 4. Now, mark the length of the mortise on the mortise piece. This is the depth to which the tenon will be inserted. 5. With the steel square, transfer the width marks from the tenon piece to the mortise piece. This will give you the exact dimensions for cutting the mortise. By using a steel square to lay out a mortise and tenon joint, you can ensure precise and accurate measurements, leading to a strong and well-fitting joint.

- Q: How do you use a steel square to ensure the correct angle for a dovetail joint?

- To use a steel square to ensure the correct angle for a dovetail joint, you need to follow a few simple steps. First, determine the angle you want to achieve for your dovetail joint. This is typically a 1:8 or 1:6 angle, with the 1:8 being more common. Next, place the steel square on the edge of the board that you will be cutting the dovetail joint into. The long side of the square should be aligned with the edge of the board, while the short side should be perpendicular to it. Now, using a pencil or a marking knife, mark a line along the short side of the square. This line will be your reference for cutting the dovetail joint. If you are using a 1:8 angle, the line should be 1/8th of an inch from the edge of the board. Similarly, for a 1:6 angle, the line should be 1/6th of an inch from the edge. You can then use this line as a guide for cutting the dovetail joint. Place the square on the edge of the board each time you need to mark another cut or make a measurement to ensure accuracy. By using a steel square in this manner, you can ensure that your dovetail joint will have the correct angle, resulting in a strong and precise joint. Remember to always double-check your measurements and make test cuts before finalizing your joint.

- Q: How do you measure angles with a steel square?

- To measure angles with a steel square, you can follow these steps: 1. Place the steel square against the edge of the material or object you want to measure the angle of. 2. Align one of the edges of the steel square with one side of the angle you want to measure. 3. Look at the scale or markings on the steel square. Typically, a steel square has a protractor scale on one of its sides. 4. Find the zero or 90-degree mark on the scale and ensure it aligns with the reference edge of the steel square. 5. Observe the angle formed by the other side of the angle you want to measure and the edge of the steel square. 6. Read the measurement on the scale where the other side of the angle intersects it. 7. Note down or memorize the measurement obtained, which represents the angle of the object or material you were measuring. Remember to hold the steel square firmly against the object or material to avoid any inaccuracies. Additionally, if the angle is larger than what the steel square can measure directly, you can use trigonometry or other methods to calculate the angle based on the measurements you obtained.

- Q: Can a steel square be used for measuring circular objects?

- No, a steel square cannot be used for measuring circular objects because it is designed for measuring right angles and straight edges.

- Q: What are the common applications of a steel square in carpentry?

- A steel square, which is also referred to as a framing square or carpenter's square, finds extensive use in carpentry for a variety of purposes. There are several common applications of a steel square including: 1. Layout and Measurement: A primary function of a steel square is to facilitate the layout and measurement of right angles. It is employed to guarantee the squareness of corners and accurately mark perpendicular lines. Carpenters often utilize it to indicate cuts on lumber, plywood, or other materials. 2. Angle Determination: Steel squares possess additional markings and scales that enable carpenters to measure and mark angles other than 90 degrees. This makes it a valuable tool for tasks such as determining the angle of a roof pitch or marking the angle for a stair stringer. 3. Level and Plumb Checking: A steel square can serve as a level or plumb line by placing one of its edges against a surface and observing if it is perfectly horizontal or vertical. This assists carpenters in ensuring that their work is level, straight, and aligned. 4. Roofing Applications: Steel squares are frequently utilized in roofing work. They can be employed to lay out common rafters, hip rafters, and bird's mouth cuts. Furthermore, the square can aid in determining the length and angles required for cutting valley rafters and jack rafters. 5. Scribing Lines: Steel squares possess a straight edge that can be utilized to scribe lines on materials. This proves helpful when fitting pieces together or marking cut lines that follow an irregular or curved shape. 6. Measurement Checking and Transfer: With its ruler-like markings, a steel square is highly effective for accurate measurement checking and transfer. Carpenters can utilize it to mark evenly spaced points, create parallel lines, or transfer measurements from one piece to another. 7. Mitre Layouts: Steel squares are commonly employed for laying out mitre cuts in trim work. They aid in determining the correct angle and length for cutting mitre joints, ensuring a precise fit when joining two pieces at a corner. In conclusion, the versatility and accuracy of a steel square render it an indispensable tool for carpenters. It guarantees precise, level, and properly aligned carpentry work, making it an essential component of any carpenter's toolbox.

- Q: How do you use a steel square to measure the height of a window opening?

- To use a steel square to measure the height of a window opening, follow these steps: 1. Position the steel square vertically against one side of the window opening, ensuring that it is flush against the side. 2. Hold the square firmly in place, making sure it is level and straight. 3. Look at the markings on the square's blade. The measurements are usually marked in inches and centimeters. 4. Starting from the bottom of the window opening, align the edge of the square's blade with the bottom edge of the opening. 5. Read the measurement on the blade at the top edge of the opening. This will give you the height of the window opening. 6. Note down the measurement and repeat the process on the opposite side of the window opening to ensure accuracy. Using a steel square provides a precise measurement of the height of a window opening, as it eliminates the risk of inaccuracy that can occur with measuring tapes or rulers.

- Q: How do you use a steel square for creating precise spline joints?

- To use a steel square for creating precise spline joints, first, measure and mark the desired length on both pieces of wood. Then, align the steel square against the edge of the wood, ensuring it is perpendicular to the surface. Next, draw a line along the edge of the steel square using a pencil or a marking knife. Repeat this process on both pieces of wood. Finally, align the marked lines and cut along them to create precise spline joints.

- Q: How do you use a steel square to measure outside corners?

- To use a steel square to measure outside corners, follow these steps: 1. Begin by placing the steel square against one side of the corner, aligning the long edge of the square with the edge of the corner. 2. Hold the steel square firmly, ensuring that it is flush against the corner. 3. Take note of the measurement on the outer edge of the square where it aligns with the other side of the corner. This measurement represents the length of the outside corner. 4. If you need to transfer this measurement to another material or surface, use a pencil or marker to mark the length on the desired location. By using a steel square, you can accurately measure the length of outside corners, ensuring precise measurements for various construction or woodworking projects.

- Q: Can a steel square be used for measuring the width of a wall opening?

- Yes, a steel square can be used for measuring the width of a wall opening. A steel square, also known as a framing square or carpenter's square, is a versatile tool that is commonly used in construction and woodworking. It has a wide range of measurements and angles marked on its face, making it suitable for various tasks. To measure the width of a wall opening, you can place the steel square against the edge of the opening and align it to ensure it is straight. The edges of the square can then be used to measure the width accurately. The square's markings will give you precise measurements, allowing you to determine the width of the wall opening with accuracy. However, it is important to note that a steel square is not the only tool that can be used for this purpose. There are other tools, such as a tape measure or a ruler, that can also provide accurate measurements. The choice of tool will depend on personal preference and the specific requirements of the task at hand.

- Q: Can a steel square be used for checking the squareness of shelf brackets?

- Certainly! The squareness of shelf brackets can indeed be checked with the aid of a steel square. An incredibly versatile tool, the steel square is frequently employed in carpentry and woodworking to assess the precision of right angles. By positioning the steel square against the corner of the shelf bracket, one can ascertain whether it is impeccably square or necessitates any modifications. Additionally, the straight edge of the steel square may be utilized to verify the appropriate alignment of the bracket with the shelf or wall. All in all, the employment of a steel square proves to be a highly effective means of examining the squareness of shelf brackets.

Send your message to us

Hot Rolled Steel Square Bar with the Size 120mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords