Aluminum Profiles Extrusion Frame for Equipment Window Door

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Frame

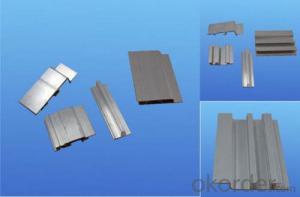

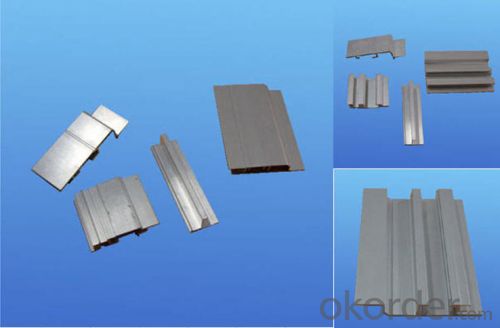

Products Introduction

Aluminum frame is made from aluminum and minerals. It's raw matrial for window frame, window frame, and other equipment frame. It's easy for construction, cost less, service longer than other materails. The size and design can be customerized.

Advantage of Aluminum Frame

-Build FLEXIBLE equipment, window, door.

-Bolt your structure together

-Build with Aluminum MORE EASILY

-Aluminum costs LESS

-Service life is more than 10 years

-Can be customerized

Specifications

(1) Product: Aluminium Frame;

(2) Material: Alloy 6063/6061/6005/6060, T5/T6;

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples;

(5) Standard: High-quality;

(6) Characteristics: strong, stylish, durable, corrosion-resistant.

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5, T6

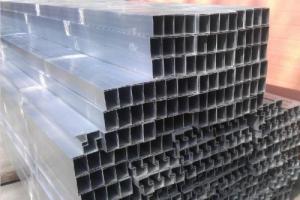

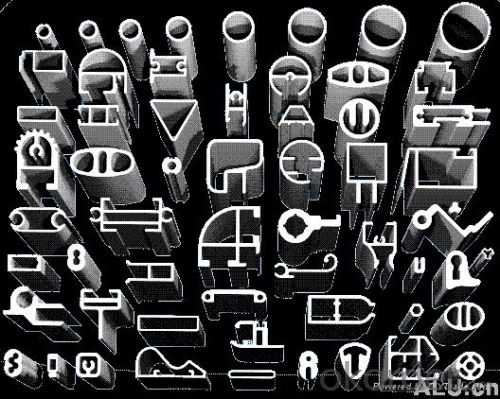

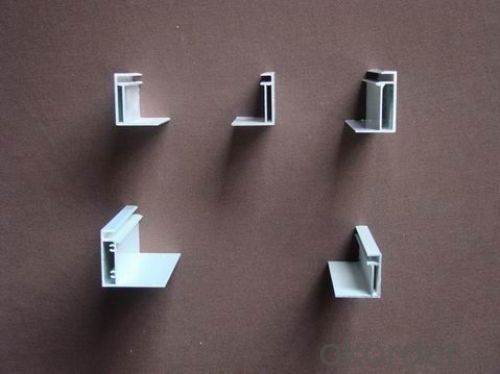

Section Shapes

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot, and other complicated shapes by custom design.

Surface treating

Mill / Anodizing (oxidation) / Sand blasting / Powder Coating / Electrophoresis / PVDFCoating / Wood effect.

Application

1) - for Window and door frames, for Wardrobe cabinet sliding doors, kitchen, for Building curtain glass walls

2) -for Fencing, Rail, Deck and Frame.

3) - for Solar panel frames, solar mounting / roofing brackets

4) - for Industry assembly lines equipment.

5) - for Heatsinks, for LED lighting.

7) - other by custom design size and dimension

FAQ

-What's your company profile?

We CNBM is the largest building material supplier of China. We are Chinese government owned corporation, which takes the 267th place in WOLD FORTUNE 500 CORPORATION. We own the largest prodcution base in North and South of China. With more than 15 warehouses and offices in different countries, our products sell very well all over the world. We have whole quality control system. We'll be your reliable partner.

-Which kind of payment do you usually support?

TT, LC at sight.

-Can you provide samples?

Yes, we provide free of charge samples, you just need to pay for the delivery.

Photos:

- Q: How much is the 5000 ton aluminum profile extrusion machine? What section can I have?

- It's more expensive than I thought. Thank you!Chasing the answerCheap, some people have to do, but large extruder manufacturers less, less than 3000 tons better.

- Q: The 50 series and the 60 series of aluminum profiles, which one is good?

- Of course, 60 of the good.60 and 50 refers to profiles, from the indoor to outdoor overall thickness of 60MM and 50MM.

- Q: Are aluminum profiles suitable for historical or heritage restoration projects?

- Historical or heritage restoration projects can benefit from the use of aluminum profiles. Aluminum, being a versatile material, offers numerous advantages for such projects. Firstly, it can be manufactured to replicate traditional architectural features and designs, seamlessly integrating and preserving the historical aesthetics. In addition, aluminum is lightweight, making it easier to handle and install, especially in complex or intricate restoration projects. It is also highly durable and resistant to corrosion, which is vital for maintaining the structural integrity and longevity of historical buildings or structures. Moreover, aluminum profiles can be easily customized and fabricated to meet the specific requirements of historical restoration projects. They can be shaped, cut, and finished to resemble the original architectural elements, such as windows, doors, trim, or decorative features. Furthermore, aluminum profiles offer excellent thermal performance, improving energy efficiency and insulation in restored buildings. This leads to reduced energy consumption, lower heating or cooling costs, and enhanced overall comfort. Although wood or steel have been commonly used in historical restoration projects, aluminum profiles provide a contemporary alternative that combines aesthetic appeal, durability, and sustainability. However, it is crucial to ensure that the use of aluminum profiles aligns with the preservation guidelines and regulations of the specific historical or heritage project. In conclusion, aluminum profiles are a suitable choice for historical or heritage restoration projects due to their versatility, durability, lightweight nature, customization options, and energy efficiency. They successfully blend modern functionality with historical aesthetics, contributing to the preservation and revitalization of our architectural heritage.

- Q: Can aluminum profiles be used in the production of packaging materials?

- Yes, aluminum profiles can be used in the production of packaging materials. Aluminum profiles offer several advantages for packaging, including lightweight and corrosion resistance properties. They can be shaped and formed into different packaging components, such as cans, tubes, foils, and containers, making them suitable for various industries, including food, beverages, pharmaceuticals, and cosmetics. Additionally, aluminum profiles provide a barrier against light, moisture, and oxygen, ensuring the quality and freshness of the packaged products.

- Q: Explain the advantages of utilizing aluminum profiles in the construction industry.

- <p>Aluminum profiles offer several benefits in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. This reduces the load on structures and facilitates easier handling and installation. They are also corrosion-resistant, ensuring longevity and low maintenance costs. Aluminum profiles are recyclable and environmentally friendly, contributing to sustainable construction practices. Their malleability allows for versatile design and customization, accommodating various architectural needs. Additionally, they have excellent thermal conductivity, which can be beneficial for heat management in buildings. Lastly, their aesthetic appeal and modern look enhance the visual appeal of construction projects.</p>

- Q: How to distinguish the true and false of aluminum profile

- Al Feng brand aluminum precision identification method is to do chemical detection. But in the absence of our conditions, we can only use "observation" to distinguish. What is "observation method", that is, we make a different perspective on the surface of aluminum. Aluminum door and window section is made of aluminum rod by die extrusion and the like, fake phoenix aluminum using bauxite as raw material, so the material contains a lot of impurities, extrusion is easy to mold galling, the surface profile produced is not smooth, there are many marks, and profiles of scrap produced. Can not be reached in a variety of physical effects on strength and hardness.The surface treatment of fake profiles for powder coating (common color: green, white, grey), said simply in this way, the profile above is squeezed out of the powder coverage, this method has great advantage on fake garbage can be squeezed out of aluminum profiles, profiles on the marks effectively cover. But because of fraud for more cost savings, they use inferior adhesion powder, short life, easy to fall off, and covered in the profile of the powder also small and thin, and extruded profile marks are too deep, even if there is a cover up the layer of powder, as long as viewed from different angles and shapes position still, it is easy to see these ugly marks.

- Q: This question asks for a method to calculate the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for your building project, first, measure the dimensions of the area where the profiles will be used. Determine the length and width of each profile required. Multiply these dimensions by the number of profiles needed for each section of the project. Add up the totals for all sections to get the overall quantity. Consider the type of profile and its application, as this will affect the quantity and specification. Factor in a small percentage for waste and cutting errors. For complex projects, consult with an engineer or use specialized software to ensure accuracy.</p>

- Q: What are the different extrusion methods used for aluminum profiles?

- There are several different extrusion methods commonly used for aluminum profiles. These methods include: 1. Direct extrusion: This is the most common method used for aluminum extrusion. In this process, a heated billet of aluminum is forced through a die using a ram. The aluminum is pushed through the die, which shapes it into the desired form. Direct extrusion is a highly efficient and cost-effective method. 2. Indirect extrusion: In this method, the billet is held stationary while the die moves towards it. The die pushes the aluminum through the stationary billet, shaping it into the desired form. Indirect extrusion is often used for more complex shapes or when a higher level of precision is required. 3. Impact extrusion: This method involves forcing a billet of aluminum into a die cavity using a punch. The punch strikes the billet with high force, causing it to flow into the die and take its shape. Impact extrusion is commonly used for producing hollow parts or tubes. 4. Hydrostatic extrusion: This method involves using a fluid, usually oil or water, to pressurize the billet and force it through a die. The high pressure of the fluid allows for greater control and precision in shaping the aluminum. Hydrostatic extrusion is often used for producing high-quality, high-strength aluminum profiles. 5. Cold extrusion: In this method, the aluminum billet is extruded at room temperature. The lower temperature helps to achieve greater strength and better surface finish. Cold extrusion is commonly used for producing small, intricate aluminum profiles. Each of these extrusion methods has its own advantages and is suitable for different applications. The choice of method depends on factors such as the complexity of the profile, desired strength, surface finish requirements, and cost considerations.

- Q: Can aluminum profiles be used in warehouse and storage systems?

- Yes, aluminum profiles can be used in warehouse and storage systems. Aluminum profiles are lightweight, durable, and corrosion-resistant, making them suitable for various applications in warehouses and storage systems. They can be used to construct shelving units, racks, and partitions to optimize storage space and organize inventory. Aluminum profiles are also known for their versatility, as they can be easily customized and assembled to meet specific storage requirements. Additionally, aluminum profiles offer excellent strength-to-weight ratio, allowing them to support heavy loads without compromising structural integrity. Overall, aluminum profiles are a popular choice in warehouse and storage systems due to their durability, flexibility, and cost-effectiveness.

- Q: How do aluminum profiles perform in earthquake-resistant structures?

- Aluminum profiles offer several advantages in earthquake-resistant structures. First and foremost, aluminum is a lightweight material, which means it has a high strength-to-weight ratio. This characteristic allows aluminum profiles to provide excellent structural integrity while minimizing the overall weight of the building. This is crucial in earthquake-prone areas as it helps reduce the forces exerted on the structure during seismic events. Additionally, aluminum is highly ductile, meaning it can deform significantly without losing its strength. This property allows aluminum profiles to absorb and dissipate seismic energy, thereby minimizing potential damage to the structure. The ductility of aluminum also ensures that it can withstand the lateral forces and vibrations generated during an earthquake, providing enhanced stability to the building. Moreover, aluminum profiles possess excellent corrosion resistance, which makes them ideal for earthquake-resistant structures in coastal regions or areas with high humidity. This corrosion resistance ensures the durability and longevity of the structure, even in harsh environmental conditions. Furthermore, aluminum profiles can be easily fabricated and assembled, offering versatility in design and construction. This flexibility allows architects and engineers to optimize the structural performance of the building, considering the specific seismic requirements of the region. In conclusion, aluminum profiles perform exceptionally well in earthquake-resistant structures due to their lightweight nature, high strength-to-weight ratio, ductility, corrosion resistance, and ease of fabrication. These characteristics make aluminum profiles a reliable choice for ensuring the safety and stability of buildings in seismic-prone areas.

Send your message to us

Aluminum Profiles Extrusion Frame for Equipment Window Door

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords