Solidworks Aluminum Extrusion Profiles for Door and Window Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile for Door and Window Frame Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile for Door and Window Frame:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

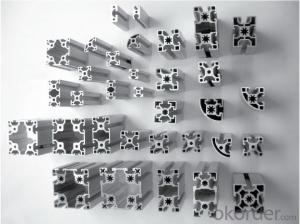

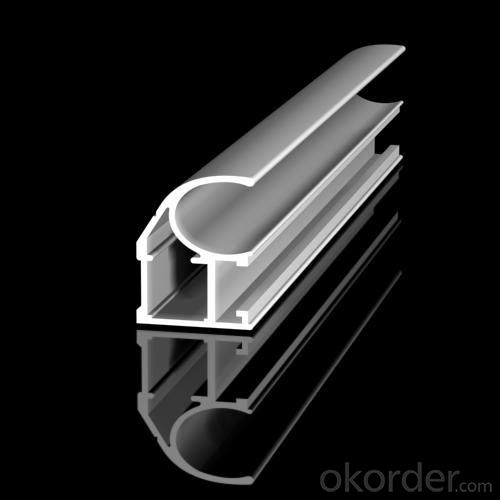

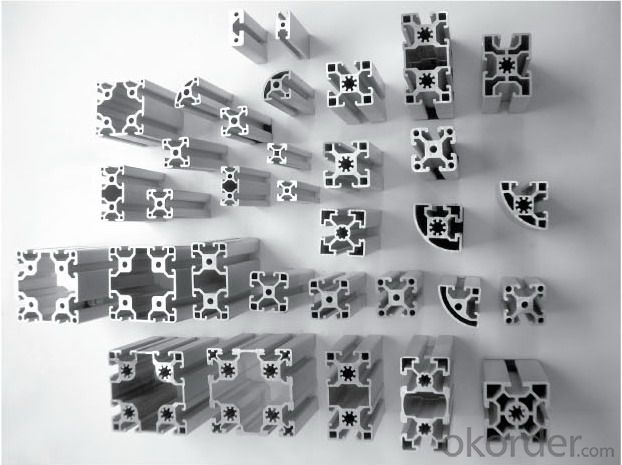

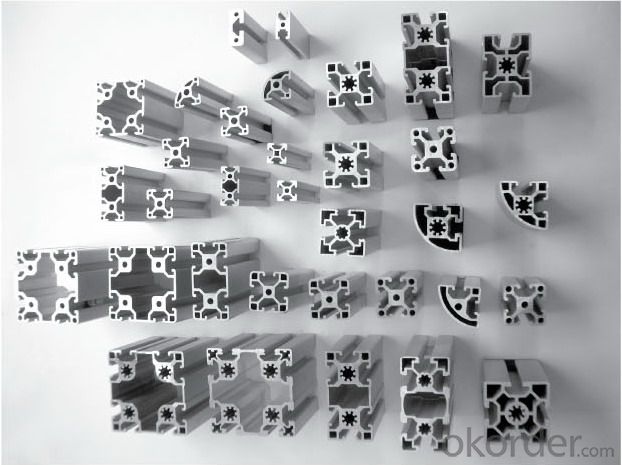

Images of the Aluminium Profile for Door and Window Frame:

Aluminium Profile for Door and Window Frame Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or ceilings.

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings due to their strength, durability, and lightweight properties. They offer design flexibility, are easy to install, and can be used in conjunction with various materials like glass or fabric. Additionally, aluminum profiles are resistant to corrosion and require minimal maintenance, making them a popular choice for both residential and commercial applications.</p>

- Q: How do you ensure proper weatherproofing with aluminum profiles?

- To ensure proper weatherproofing with aluminum profiles, it is essential to consider three key aspects: proper installation, effective sealing, and regular maintenance. Firstly, the profiles should be installed correctly, ensuring tight joints and secure fastening to prevent water leakage. Secondly, applying high-quality sealants or gaskets at the joints and corners helps to create a watertight barrier. Lastly, regular inspection and maintenance, such as checking for any damage or wear and resealing as needed, will help maintain the weatherproofing effectiveness of aluminum profiles over time.

- Q: This question asks for a variety of green building materials that incorporate recycled aluminum profiles, indicating an interest in sustainable construction practices.

- <p>Recycled aluminum profiles are used in various green building materials to promote sustainability. These include: 1) Window and door frames, known for their durability and energy efficiency. 2) Facade systems, which provide a lightweight and strong alternative to traditional materials. 3) Structural components, such as beams and columns, offering strength with less material. 4) Roofing materials, which can be lightweight and resistant to corrosion. 5) Modular building systems, which use prefabricated aluminum components for quick assembly. 6) Fencing and railings, offering a low-maintenance option. 7) Solar panel supports, combining recycled aluminum with renewable energy technology. These materials reduce waste, save energy, and lower carbon emissions in construction.</p>

- Q: Aluminum profiles 1, 2, 3, 4, 5, 7, 6, 8 line characteristics, what is the difference, please master more advice

- The alloy of 7 strength, welded structural alloy, solid profile alloy seems to be a shell case. Military companies have had this order beforeIt's too general. There are many alloys in each department

- Q: Can aluminum profiles be used for skylights?

- Skylights can indeed utilize aluminum profiles. The durability, strength, and corrosion resistance of aluminum make it a popular choice for skylight frames. Its lightweight yet robust nature ensures the skylight glass is adequately supported and guarantees long-lasting performance. Furthermore, aluminum profiles can be effortlessly tailored and molded to meet specific design needs, enabling a wide range of skylight styles and sizes. Incorporating aluminum profiles in skylights also offers exceptional thermal insulation, promoting energy efficiency by minimizing heat transfer and condensation. In summary, aluminum profiles are a dependable and pragmatic choice for skylight construction.

- Q: What are the potential health risks associated with handling aluminum profiles?

- <p>Working with aluminum profiles generally does not pose significant health concerns under normal conditions. However, there are a few considerations. Inhalation of aluminum dust can cause respiratory issues, and prolonged exposure may lead to a condition known as 'aluminum dust disease.' Additionally, aluminum can cause skin irritation in some individuals, especially with prolonged contact. It's important to use proper personal protective equipment (PPE), such as masks and gloves, to minimize these risks. Ingestion of aluminum is also a concern, as it can lead to health problems if it enters the body through contaminated food or water, although this is not directly related to handling aluminum profiles.</p>

- Q: Can aluminum profiles be used for electrical applications?

- Aluminum profiles possess the capability to be utilized in electrical applications. Given its high conductivity, aluminum emerges as an ideal choice for facilitating electrical conduction. In the realm of electrical applications, aluminum profiles frequently find employment in power distribution systems, wiring conduits, and bus bars. By virtue of being lightweight and cost-effective, they present a favorable solution for electrical installations. Moreover, aluminum profiles exhibit commendable thermal conductivity, successfully aiding in the dissipation of heat emitted by electrical components. Nevertheless, it remains crucial to duly factor in the specific requirements of the electrical application at hand, ensuring that the aluminum profiles adhere to the requisite electrical safety standards and regulations.

- Q: What is the nitriding process of aluminum extrusion die?

- The principle of nitridation:Gas nitrocarburizing, that is gas nitrocarburizing, refers to low temperature nitrocarburizing based on gas nitriding and carburizing. Commonly used media have 50% ammonia, +50% endothermic gas (Nitemper method); 35%-50% ammonia, +50-60% exothermic gas (Nitroc method) and ammonia through the drip ethanol or formamide and so on. In soft nitriding, because of the high solubility of carbon atoms in the epsilon phase, the soft nitrided surface is a common compound of carbon and nitrogen, which is good in toughness and wear resistant.In the process of gas nitrocarburizing, due to the extremely low solubility of carbon atoms, it quickly reaches saturation state and precipitates many super micro cementite points. These cementite particles, as the core of the crystallization of nitrides, contribute to the formation of nitrides. When the surface nitrogen concentration reaches a certain level, the epsilon phase is formed, while the carbon solubility of the epsilon phase is very high, which in turn accelerates the dissolution of carbon.After gas nitrocarburizing, its structure is composed of epsilon phase, gamma phase and nitrogen containing cementite Fe3 (C, N), carbon will reduce the diffusion rate of nitrogen, so the thermal stress and the stress of the tissue are hard, the nitriding is large and the layer is thinner. But at the same time, because the soft nitride layer does not exist. Therefore, the nitride layer, better toughness than hard nitriding

- Q: Can aluminum profiles be used for soundproofing?

- Aluminum profiles have the ability to offer some soundproofing benefits, although they may not provide the same level of sound reduction as specialized soundproofing materials like acoustic panels or insulation. These profiles are commonly used in the construction industry for various purposes, such as window frames and door frames. When incorporated into soundproofing applications, aluminum profiles can effectively minimize noise transmission through windows and doors. The lightweight and durable nature of aluminum makes it an ideal material for blocking or dampening sound waves. Its structural integrity allows for the creation of tight seals, resulting in reduced sound leakage and improved sound insulation. To further enhance soundproofing, aluminum profiles can be combined with other materials like rubber gaskets or weatherstripping. This combination enhances the sealing properties and contributes to better sound insulation. Additionally, the use of double or triple glazing with laminated glass in conjunction with aluminum profiles can provide even better sound insulation. However, it is important to consider that the effectiveness of aluminum profiles in soundproofing depends on various factors. These factors include the thickness and quality of the profiles, the design of the window or door system, and the overall construction of the building. In conclusion, while aluminum profiles can assist in reducing noise transmission through windows and doors, they should be viewed as part of a comprehensive soundproofing strategy rather than the sole solution.

- Q: Is it feasible to recycle aluminum profiles and what factors affect the recycling process?

- <p>Yes, aluminum profiles can be recycled easily. Aluminum is one of the most recycled materials globally due to its low melting point, which requires less energy for recycling compared to other metals. The recycling process involves melting the aluminum, which can be done at temperatures significantly lower than those needed for other metals. Additionally, aluminum retains its properties even after multiple recycling cycles, making it an ideal material for sustainable use. The recycling rate of aluminum is high, and it contributes to energy savings and reduced environmental impact. However, the ease of recycling can be affected by factors such as the presence of impurities, the complexity of the profile shapes, and the efficiency of collection systems.</p>

Send your message to us

Solidworks Aluminum Extrusion Profiles for Door and Window Frame

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords