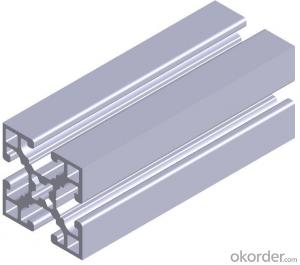

Aluminum Cladding Profiles for Heat Radiator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum profile.heat sink profile

1.Short lead time: 7-15days.

2.professional technology supports.

3.Factory direct price

aluminum profile,industrial aluminum extrusion, construction aluminum profile

Feature:

Specification: according to your aluminum profile drawing or sample

Alloy Code: 6063-T5.6061-T6 o

Surface treatment:

Mill finish

electrophresis

Anodized(silver anodizing,bronze anodizing,champagne anodizing,etc.),

powder coating (need your confirmation by the panton colour, such as RAL9001 )

Length: no more 6.0 M

Sample time: about 13 days o

Lead time:

about 20 days for 1x40' feet

package:

Shrink film and wrapper, kraft paper ,plastic film or per client's requirement.

price: A00(SMM)+Processing fee

payment :

30% deposit +70% before the delivery or against the copy of B/L

delivery : 15-25 days after the deposit confirmed

- Q: How much is the 5000 ton aluminum profile extrusion machine? What section can I have?

- 5000 tons press, plus auxiliary machine, installed finished, almost 50 million -1 million, this depends on the configuration. Cheap certainly also domestic, but a penny a cent goods.A general can reach the maximum about 400mm.

- Q: Are aluminum profiles suitable for use in pharmaceutical manufacturing?

- Pharmaceutical manufacturing can benefit greatly from the use of aluminum profiles. These profiles offer a range of advantages in the industry due to the versatile and lightweight nature of aluminum. One crucial advantage is the corrosion resistance of aluminum profiles, which is of utmost importance in pharmaceutical manufacturing where cleanliness and hygiene are vital. Aluminum does not rust or deteriorate when exposed to moisture, making it an ideal material for cleanrooms and sterile environments. Furthermore, aluminum profiles are easy to clean and maintain, maintaining their structural integrity even after rigorous cleaning processes such as sterilization and disinfection. This ensures that the pharmaceutical manufacturing equipment remains in a pristine and contamination-free condition. Customization is another key benefit of aluminum profiles in pharmaceutical manufacturing. These profiles can be easily fabricated into various shapes and sizes, allowing for the creation of complex structures and machinery. This flexibility makes aluminum profiles an excellent choice for designing precise pharmaceutical equipment, including conveyor systems, processing machinery, and packaging equipment. Additionally, aluminum profiles possess excellent thermal conductivity, which is advantageous in pharmaceutical manufacturing processes that involve temperature control. Freeze-drying, sterilization, and granulation, for example, can benefit from efficient heat transfer provided by aluminum profiles. This ensures that pharmaceutical products are processed and stored at the desired temperature. Lastly, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable, reducing the carbon footprint associated with pharmaceutical manufacturing. The ability to reuse and repurpose aluminum profiles contributes to a circular economy and minimizes waste generation. In conclusion, aluminum profiles are highly suitable for pharmaceutical manufacturing. Their corrosion resistance, ease of cleaning, customization options, thermal conductivity, and sustainability make them an excellent choice for designing and fabricating pharmaceutical equipment and machinery.

- Q: This question asks about the various applications of aluminum extrusions within the automotive manufacturing industry.

- <p>Aluminum extrusions are widely used in automotive manufacturing due to their lightweight, high strength, and corrosion resistance. They are utilized in several areas: 1) Structural components such as chassis, frames, and body parts to reduce vehicle weight and improve fuel efficiency. 2) Engine components to enhance engine performance and durability. 3) Heat exchangers and radiators for effective cooling systems. 4) Crash management systems to absorb impact during collisions. 5) Interior components like dashboards and door panels for lightweight and aesthetic appeal. 6) Electrical components such as battery casings and wiring harnesses. 7) Wheels and suspension components for improved handling and reduced unsprung weight. These applications contribute to the overall performance, safety, and efficiency of vehicles.</p>

- Q: Aluminum prices are calculated by the meter, or how to quote the ah?

- Yes, for example, today's aluminum price, 10340+ processing fee 4000=14340, in addition to 1000 is equal to 14.34 yuan /KG

- Q: What are the minimum thickness specifications for aluminum alloy door and window profiles?

- 2, GB8479, 2005, "aluminum alloy door" in 5.1: aluminum alloy door force components should be determined by test or calculation. The minimum measured wall thickness shall be greater than 2.0mm without the surface treated profiles.

- Q: Are aluminum profiles suitable for use in the renewable energy industry?

- Yes, aluminum profiles are suitable for use in the renewable energy industry. Aluminum is lightweight, durable, and corrosion-resistant, making it ideal for applications such as solar panel frames, wind turbine components, and electrical infrastructure. It also offers excellent thermal conductivity and recyclability, aligning with the sustainability goals of the renewable energy sector.

- Q: Are aluminum profiles resistant to termites and insects?

- Yes, aluminum profiles are resistant to termites and insects.

- Q: What kind of equipment are needed for the production of aluminum profiles?

- The production of aluminum equipment not hundreds of several decades, from the beginning, homogeneous casting furnace, extrusion machine, anodic electrophoretic coating production line groove, powder powder production line, fluorocarbon paint production line, insulated aluminum production line, processing workshop welding riveting, stitching and other processing equipment. Plus to die do I still have, cars, milling, grinding, drilling, EDM, wire cutting, and other processing equipment. I am now in a small department work of aluminum processing company.

- Q: What is the nitriding process of aluminum extrusion die?

- Aluminum extrusion die manufacturing process, extrusion die process is generally as follows:Put forward the mold task (profile drawing)HereDie design for forging blank, annealing and extrusionDown hereTurning procedure checkDown hereCoarse grinding plane, crossed through NC program tape or tapeHereDrilling and millingHereTo test the electrode machining EDM..HereHeat treatment line cutting processHereInspection and correction of grindingHereExtrusion honingHereExtrusion, mold testing and fixing the nitriding treatment

- Q: This question asks about potential health hazards related to the use of aluminum profiles in construction.

- <p>There are minimal health risks associated with using aluminum profiles in building construction. Aluminum is a non-toxic metal and does not emit harmful substances. However, during the manufacturing process, if not properly controlled, there might be concerns related to dust and fumes. Additionally, aluminum can react with other materials, potentially causing corrosion or weakening the structure. It's important to ensure that aluminum profiles are used in accordance with safety standards and guidelines to mitigate any potential risks.</p>

Send your message to us

Aluminum Cladding Profiles for Heat Radiator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords