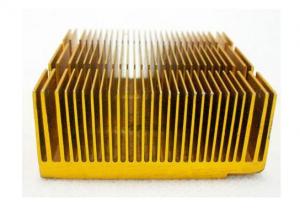

Aluminum Heat Sink Stock

Aluminum Heat Sink Stock Related Searches

Aluminum Heatsink Stock Aluminum Stock Aluminum Price Stock Aluminum Metal Stock Aluminum Shim Stock Aluminum Hinge Stock Aluminum Stock Tank Aluminum Ak Stock Aluminum Tubing Stock Aluminum Lathe Stock Aluminum Mill Stock Aluminum Gun Stock Aluminum Pipe Stock Aluminum Laminated Shim Stock Aluminum Machining Stock Aluminum Box Stock Aluminum Heat Sink Plate Stock Aluminum Aluminum Frame Stock Aluminum Block Stock Aluminum Commodity Stock Aluminum Butt Stock Aluminum Ar Stock Aluminum Fin Stock Aluminum Stock Tanks Aluminum Spacer Stock Aluminum Chassis Stock Hydro Aluminum Stock Ak Aluminum Stock Aluminum Stock PriceAluminum Heat Sink Stock Supplier & Manufacturer from China

Aluminum Heat Sink Stock encompasses a wide range of aluminum-based heat sinks designed to dissipate heat efficiently. These products are crafted from high-quality aluminum, known for its excellent thermal conductivity and lightweight properties, making them ideal for various electronic devices and systems. The aluminum heat sinks are designed to maintain optimal temperature levels, ensuring the longevity and performance of electronic components.Aluminum Heat Sink Stock finds its application in a multitude of scenarios, including computer processors, power supplies, LED lighting, and telecommunications equipment. They are used to manage heat generated by these devices, preventing overheating and maintaining efficient operation. By dissipating heat effectively, these heat sinks contribute to the overall reliability and stability of the systems they are integrated into.

Okorder.com stands as a prominent wholesale supplier of Aluminum Heat Sink Stock, boasting a vast inventory that caters to diverse customer needs. With a commitment to quality and competitive pricing, Okorder.com ensures that customers have access to a comprehensive selection of aluminum heat sinks to suit their specific requirements.

Hot Products