Extruded Aluminum Profiles for Air Handling Unit Case with Thermal Break

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

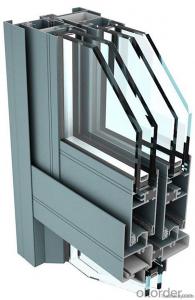

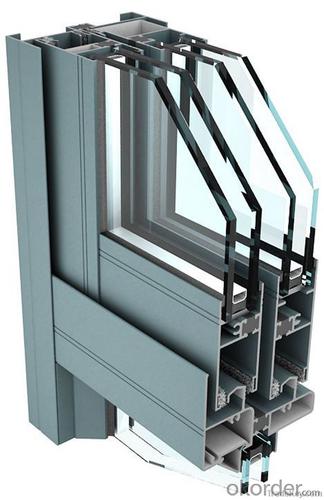

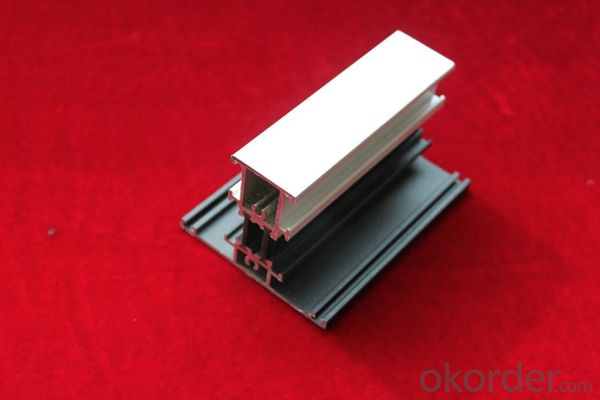

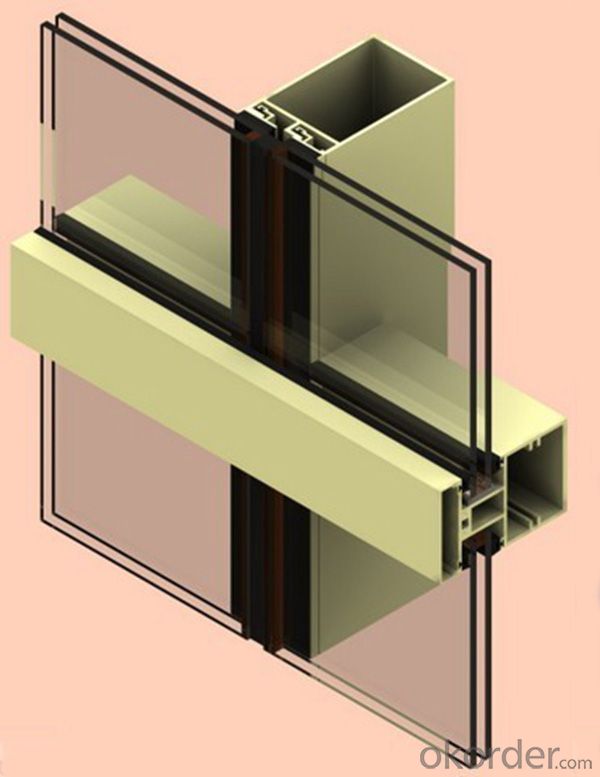

5. Image of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

6. Package and shipping of Air Handling Unit Case Aluminum Extrusion Profile With Thermal Break

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Can aluminum profiles be used for framing mirrors?

- Yes, aluminum profiles can be used for framing mirrors. Aluminum is a versatile and lightweight material that provides a sleek and modern look to any mirror frame. It is commonly used in various industries, including architecture and interior design, due to its durability, corrosion resistance, and ease of customization. Aluminum profiles come in a variety of shapes and finishes, allowing for endless design possibilities to match any style or decor. Additionally, aluminum frames are easy to install and maintain, making them a popular choice for framing mirrors in both residential and commercial settings.

- Q: Are aluminum profiles suitable for outdoor furniture and fences?

- <p>Yes, aluminum profiles are commonly used for outdoor furniture and fences due to their durability, resistance to corrosion, and low maintenance requirements. Aluminum doesn't rust like iron or steel, making it ideal for outdoor applications where exposure to weather elements is constant. It also retains its structural integrity over time and can be easily powder-coated or anodized for added protection and aesthetic appeal.</p>

- Q: Identify the key elements to evaluate when choosing aluminum profiles for a particular project.

- <p>When selecting aluminum profiles for a specific project, consider the following factors: 1) Load-bearing capacity, ensuring the profile can support the intended weight and stress; 2) Dimensional stability, to maintain structural integrity over time; 3) Corrosion resistance, especially for outdoor or humid environments; 4) Aesthetics, matching the profile's appearance with the project's design; 5) Cost-effectiveness, balancing quality with budget constraints; 6) Availability of the profile, considering lead times and supply chain reliability; 7) Ease of fabrication and assembly, which can affect construction time and labor costs; 8) Thermal properties, important for energy efficiency in buildings; 9) Compliance with industry standards and regulations; 10) Customizability, for projects with unique specifications or design requirements.</p>

- Q: This question asks for a comparison between aluminum profiles and other materials commonly used for roofing, focusing on their characteristics and performance.

- <p>Aluminum profiles for roofing are known for their durability, corrosion resistance, and lightweight nature. Compared to materials like steel, they are less prone to rust and offer a longer lifespan with minimal maintenance. When compared to traditional materials like wood or clay tiles, aluminum profiles are more resistant to weathering and do not rot or warp. They also have a high strength-to-weight ratio, making them ideal for structures that require lighter roofing materials. Additionally, aluminum profiles can be easily recycled, contributing to sustainability efforts. However, they may not offer the same aesthetic appeal as traditional materials and can be more expensive upfront.</p>

- Q: This question asks for methods to prevent rust formation on aluminum profiles during the periods of storage and transportation.

- <p>To prevent rust on aluminum profiles during storage and transportation, follow these guidelines: 1. Keep aluminum profiles dry and clean, avoiding contact with moisture or corrosive substances. 2. Store profiles in a cool, dry place, away from direct sunlight and heat sources. 3. Use protective packaging materials to shield profiles from physical damage and moisture. 4. Apply a protective coating or sealant to the aluminum surface if it's exposed to harsh environments. 5. Regularly inspect stored profiles for signs of corrosion and address any issues promptly. By adhering to these practices, you can minimize the risk of rust formation on aluminum profiles during storage and transportation.</p>

- Q: Explain the various uses of aluminum profiles in architectural design.

- <p>Aluminum profiles have a wide range of applications in architectural design due to their strength, durability, and versatility. They are commonly used for curtain walls, which provide a sleek and modern appearance while offering thermal insulation. Aluminum profiles are also used in window and door frames for their lightweight and strong properties, enhancing security and energy efficiency. They are integral in the construction of sun shading systems and louvers, which help control light and heat in buildings. Additionally, aluminum profiles are used in structural components like beams and columns, as well as in decorative elements such as facades and balustrades, offering both functional and aesthetic benefits.</p>

- Q: Can aluminum profiles be used for soundproofing or acoustic applications?

- Yes, aluminum profiles can be used for soundproofing or acoustic applications. Aluminum is known for its excellent sound-dampening properties, making it an ideal material for creating sound barriers or enclosures. Its structural rigidity and ability to absorb or reflect sound waves can effectively reduce noise transmission. Additionally, aluminum profiles can be easily customized and fabricated into different shapes and sizes to suit specific acoustic requirements. Whether used in walls, partitions, doors, or enclosures, aluminum profiles can help minimize the transfer of sound, providing a quieter and more comfortable environment.

- Q: This question asks about the various finishing options that can be applied to aluminum profiles.

- <p>Aluminum profiles can be finished in several ways to enhance their appearance and durability. Common types of finishes include: 1. Anodizing, which provides a protective oxide layer and can be colored. 2. Powder coating, a durable and customizable finish that offers a wide range of colors and textures. 3. Electrophoretic coating, which results in a smooth, even finish and is often used for automotive parts. 4. Polishing, which can produce a mirror-like finish. 5. Brushing, which creates a鍝戝厜 texture with a satin-like appearance. 6. Painting, which can be done with solvent-based or water-based paints for a variety of color options. 7. Wood grain transfer, which gives aluminum profiles the appearance of wood. Each finish has its own advantages and is chosen based on the specific application and aesthetic requirements.</p>

- Q: How to distinguish the good or bad of aluminum profile simply?

- With customers in the process of aluminum found billion purchase of aluminum profile, most do not know how to see the quality of aluminum profiles. And sometimes, many users in order to save costs, and select some cheaper industrial aluminum to do the work table stent, resulting in not long after the emergence of cracking, fading situation.

- Q: Can aluminum profiles be used for access control systems?

- Yes, aluminum profiles can be used for access control systems. Aluminum profiles are commonly used in the construction of access control systems due to their durability, lightweight nature, and corrosion resistance. They provide a sturdy framework for mounting access control devices such as card readers, keypads, and biometric scanners. Additionally, aluminum profiles offer flexibility in design and can be easily customized to fit specific requirements of access control systems.

Send your message to us

Extruded Aluminum Profiles for Air Handling Unit Case with Thermal Break

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords