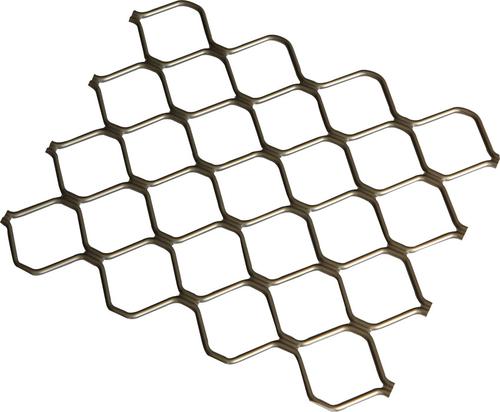

China Aluminum Frame Extrusion Profiles for Aluminum Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINUM MESH

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: What are the specifications of aluminium alloy door and window profiles?

- The aluminum alloy door and window profiles of the same size series are quite complex in shape and size. Must be analyzed and treated in accordance with the drawings.The section of aluminum door and window profile is divided into solid section and hollow section according to the shape of section, and the application of hollow profile is larger.Aluminum door and window profiles of wall thickness, for aluminum alloy window of not less than 1.4mm, with aluminum alloy door is not less than 2mm.The length, size, dividing ruler, double ruler and indefinite ruler of aluminum door and window profiles are three kinds. Fixed length generally not more than 6m, variable length is not less than 1m.

- Q: What are the different colors and finishes available for aluminum profiles?

- Aluminum profiles offer a wide array of colors and finishes for customization and design versatility. The available options include anodized finishes, which involve creating a durable oxide layer through an electrochemical process. This not only provides color choices like silver, black, white, bronze, and gold but also enhances corrosion resistance and durability. In addition to anodizing, powder coating is a popular method for achieving different colors and finishes. It involves applying a dry powder electrostatically and then heat-curing it for a smooth, strong, and uniform result. This technique offers a broad range of colors, including metallic, matte, gloss, and textured finishes. Moreover, liquid paint can also be utilized to paint aluminum profiles, offering limitless color possibilities. This makes it perfect for projects with unique design requirements, as the finishes can be customized to match specific color needs. To summarize, aluminum profiles can be finished with anodized options like silver, black, white, bronze, and gold, as well as powder coating finishes such as metallic, matte, gloss, and textured. Additionally, liquid paint allows for virtually any desired color. These choices ensure design flexibility and enable aluminum profiles to complement various architectural and industrial applications.

- Q: How to sell and sell industrial aluminium profiles?

- The production of industrial aluminum profiles is made in accordance with the requirements of the order and can be understood as customized, so this will cause some degree of limitations. In other words, the needs of an enterprise may not be appropriate for another enterprise. Therefore, this requires that we must know more about the needs of our customers when we are selling. In addition, the demand for industrial aluminum customers is mostly long-term, so long-term supply is needed. Therefore, for industrial aluminum profiles, the quantity of orders does not lie in quantity, but in quantity. The quantity of customer demand is much, and the cooperation cycle is long.

- Q: This question asks whether aluminum profiles are susceptible to damage from moisture and corrosion.

- <p>Aluminum profiles are generally resistant to moisture and corrosion due to their natural protective oxide layer. However, this resistance can be compromised in certain conditions. For instance, in highly corrosive environments or when exposed to aggressive chemicals, the protective layer may not be sufficient. Additionally, if the aluminum is not properly sealed or coated, it can still be affected by moisture over time. It's important to maintain the integrity of the protective layer and consider the specific environment when using aluminum profiles to ensure their longevity and resistance to corrosion.</p>

- Q: This question asks for an overview of the various types of aluminum profiles that are utilized in the construction of interior partitions and ceilings.

- <p>Aluminum profiles for interior partitions and ceilings come in various types, each serving specific purposes and functions. Common types include: 1. U-Channel profiles, used for creating the framework of ceilings and partitions. 2. T-profiles, often used as a cover for the joints between panels. 3. H-profiles, which are used as main beams in ceiling systems. 4. Angle profiles, used for corner connections and support. 5. Flat bar profiles, used for decorative or functional purposes in ceilings and partitions. 6. Box profiles, which can be used for both structural and aesthetic applications. 7. Special profiles, designed for specific applications such as lighting fixtures or air conditioning ducts. These profiles are chosen based on the design requirements, load-bearing needs, and aesthetic preferences for the project.</p>

- Q: What are the different cutting methods for aluminum profiles?

- There are several cutting methods for aluminum profiles, including sawing, shearing, milling, and laser cutting. Sawing is commonly used for straight cuts and can be done manually or with a powered saw. Shearing involves using sharp blades to cut through the aluminum, typically for thin profiles. Milling involves using a rotating cutter to remove material and create complex shapes. Laser cutting uses a high-powered laser beam to melt or vaporize the aluminum, offering precise and clean cuts. The choice of cutting method depends on the desired shape, thickness, and accuracy required for the aluminum profiles.

- Q: This question asks about the various types of aluminum profiles that are utilized in flooring systems, seeking to understand their specific applications and characteristics.

- <p>Aluminum profiles for flooring systems are designed for specific purposes and come in various types, including: 1. T-profiles, which are used as support beams for raised access floors; 2. L-profiles, often used for edge trims and transitions; 3. H-profiles, serving as main beams in the flooring structure; 4. U-channels, used for cover strips and edge protection; 5. C-profiles, which can be used for cable management within the floor void; 6. Z-profiles, suitable for joint covers and transitions. These profiles are chosen based on the load-bearing requirements, aesthetic considerations, and specific structural needs of the flooring system.</p>

- Q: Can aluminum profiles be used in the construction industry?

- The construction industry can utilize aluminum profiles, which possess qualities such as being lightweight, durable, and resistant to corrosion. These attributes make them suitable for a wide range of construction applications. Aluminum profiles are commonly employed in the production of windows, doors, curtain walls, and structural framing systems. They offer an excellent strength-to-weight ratio, enabling the creation of large and intricate structures without excessive weight. Furthermore, they are easily molded into various shapes and sizes, providing flexibility in design and construction. The thermal conductivity of aluminum profiles is also advantageous, as it allows for efficient insulation and energy conservation. All in all, due to their versatility, durability, and aesthetic appeal, aluminum profiles are a favored choice in the construction industry.

- Q: Can aluminum profiles be used in green building projects?

- Green building projects can utilize aluminum profiles effectively. Aluminum, being an eco-friendly material, offers numerous advantages in the realm of green building. To begin with, aluminum's lightweight nature cuts down on transportation costs and energy consumption during construction. Furthermore, aluminum is entirely recyclable, ensuring that it can be reused indefinitely without any loss in quality. This characteristic makes aluminum an ideal option for green building projects as it aids in waste reduction and promotes a circular economy. Additionally, aluminum boasts a lengthy lifespan and necessitates minimal upkeep, further enhancing its sustainability. It is worth noting that aluminum profiles can easily be integrated with other green building materials like glass, enabling energy-efficient designs that maximize natural light and minimize the reliance on artificial lighting. In conclusion, aluminum profiles offer a sustainable and versatile choice for green building projects.

- Q: What are the weatherproofing properties of aluminum profiles?

- Aluminum profiles have excellent weatherproofing properties due to their inherent characteristics and manufacturing processes. Aluminum is a naturally corrosion-resistant material, which means it can withstand exposure to various weather conditions without deteriorating or rusting. It forms a thin layer of oxide on its surface, providing an additional barrier against moisture and preventing further corrosion. Additionally, aluminum profiles can be further enhanced with various weatherproofing techniques. One common method is anodizing, where the aluminum surface is treated with an electrolytic process to create a thicker and more durable oxide layer. This not only improves the weather resistance but also enhances the profile's resistance to scratching and wear. Furthermore, aluminum profiles can be coated with different protective finishes, such as powder coating or liquid paint. These coatings not only provide an aesthetic appeal but also serve as an extra layer of protection against UV radiation, moisture, and other weather elements. Powder coating, in particular, offers superior durability and resistance to fading, chipping, and cracking. Moreover, aluminum profiles can be designed to incorporate weatherproof features such as gaskets, seals, and thermal breaks. These elements create a tight seal between the profile and other building components, preventing water infiltration, air leakage, and thermal transfer. They help maintain a comfortable indoor environment, reduce energy consumption, and enhance the overall weatherproofing performance of the aluminum profiles. Overall, the weatherproofing properties of aluminum profiles make them a popular choice for various applications, including windows, doors, curtain walls, roofing systems, and outdoor furniture. Their ability to withstand harsh weather conditions, resistance to corrosion, and available protective coatings make them a reliable and durable option for both residential and commercial projects.

Send your message to us

China Aluminum Frame Extrusion Profiles for Aluminum Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords